Loading test device for dynamic braking linear motors

A linear motor and energy-consumption braking technology, which is applied in the direction of motor generator testing, etc., can solve the problems of non-continuous adjustment and unidirectional test loading force, etc., and achieve the effect of simple structure, elimination of loading force fluctuation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

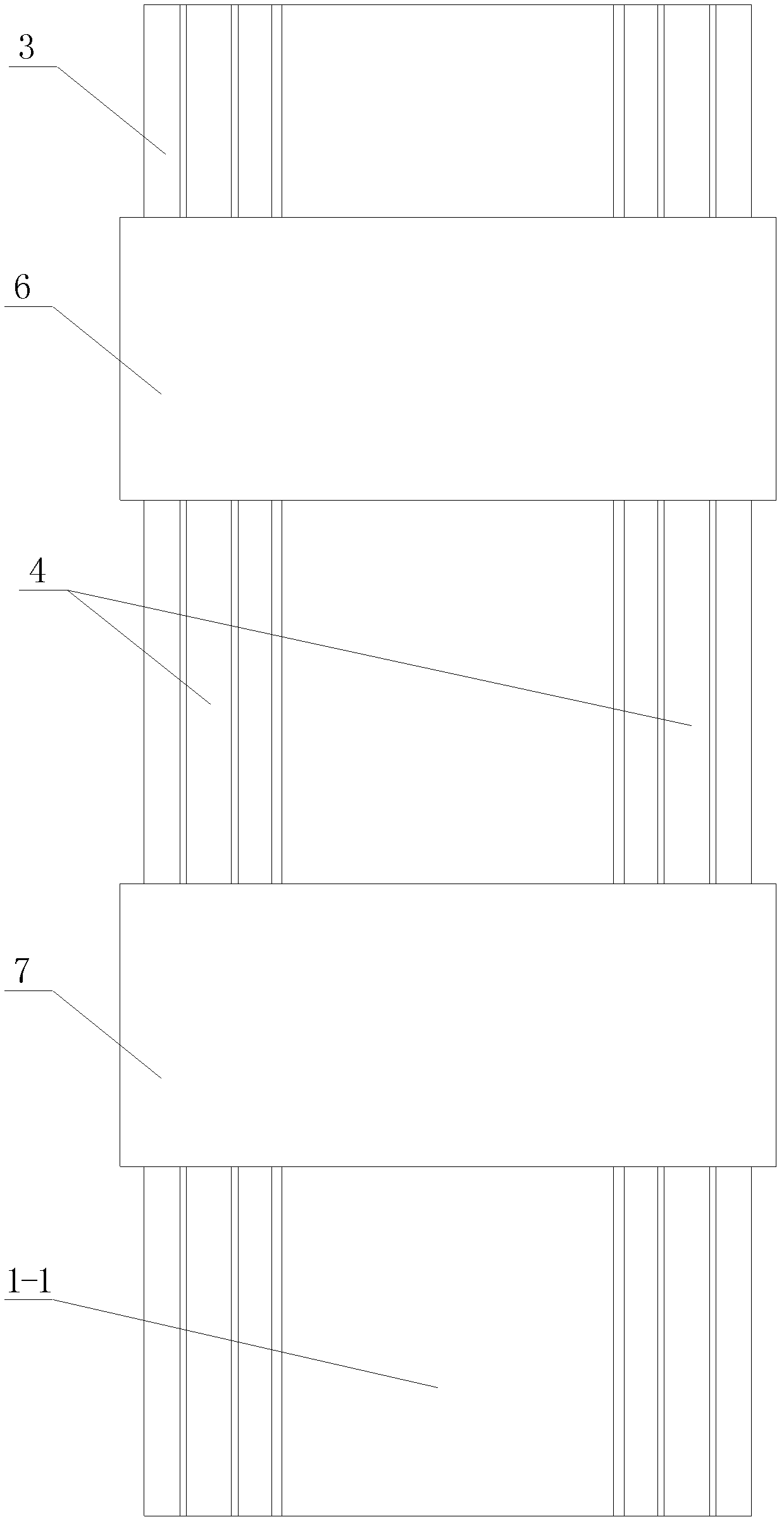

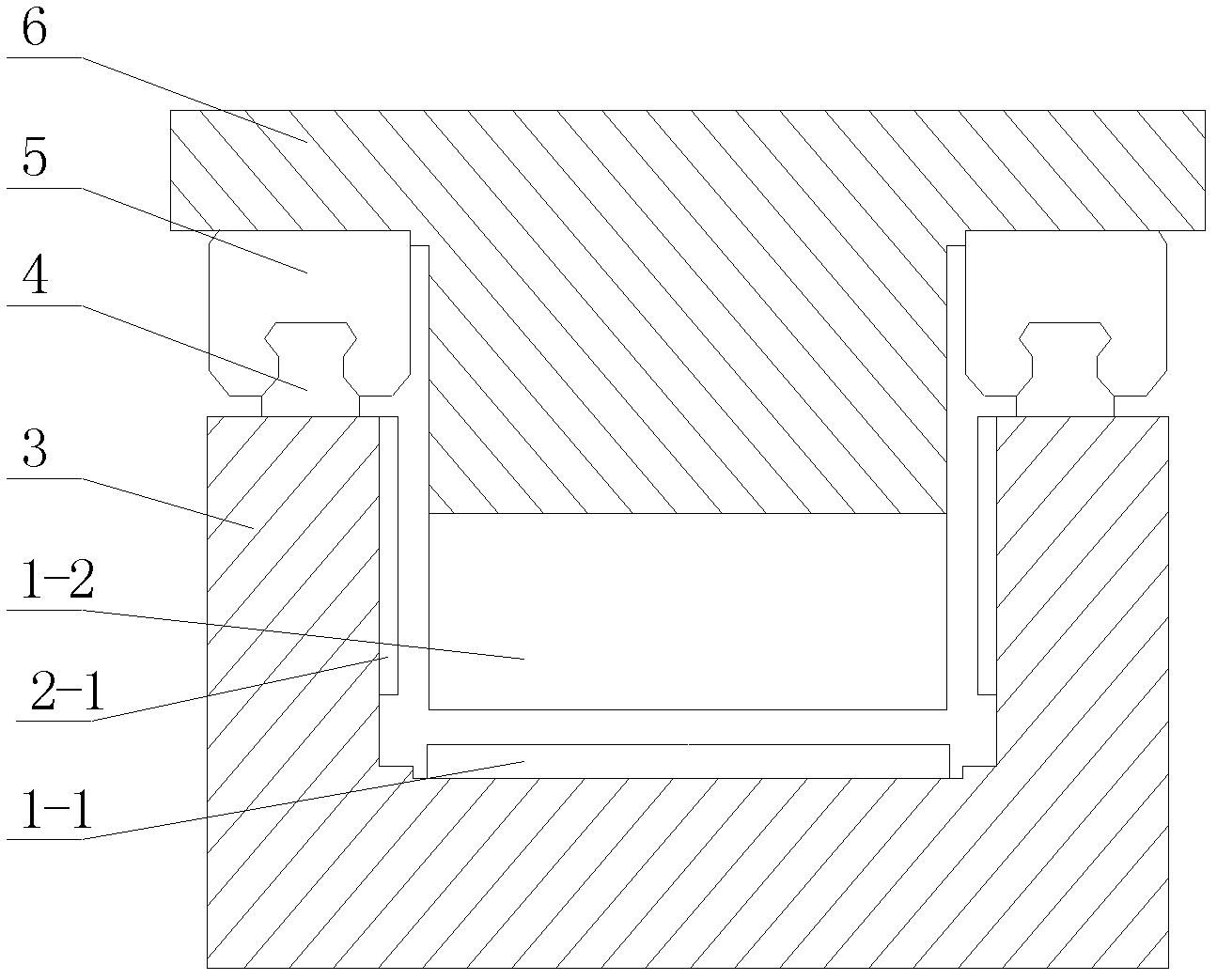

[0041] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the dynamic braking type linear motor test loading device described in this embodiment includes a linear motor to be tested, and it also includes a linear brake for loading, a table body 3, a support guide rail 4, a sliding frame 6 for the motor under test, Load brake carriage 7, force transducer and displacement transducer,

[0042] The table body 3 is a U-shaped structure, and support guide rails 4 are arranged symmetrically on the upper surfaces of the two vertical sections of the table body 3. The measuring motor sliding frame 6 is slidingly connected with the supporting rail 4 through the rail slider 5, and the loading brake sliding frame 7 is slidingly connected with the supporting rail 4 through the rail sliding block 5,

[0043] The motor stator 1-1 of the linear motor under test is fixedly installed on the inner surface of the horizontal section of the t...

specific Embodiment approach 2

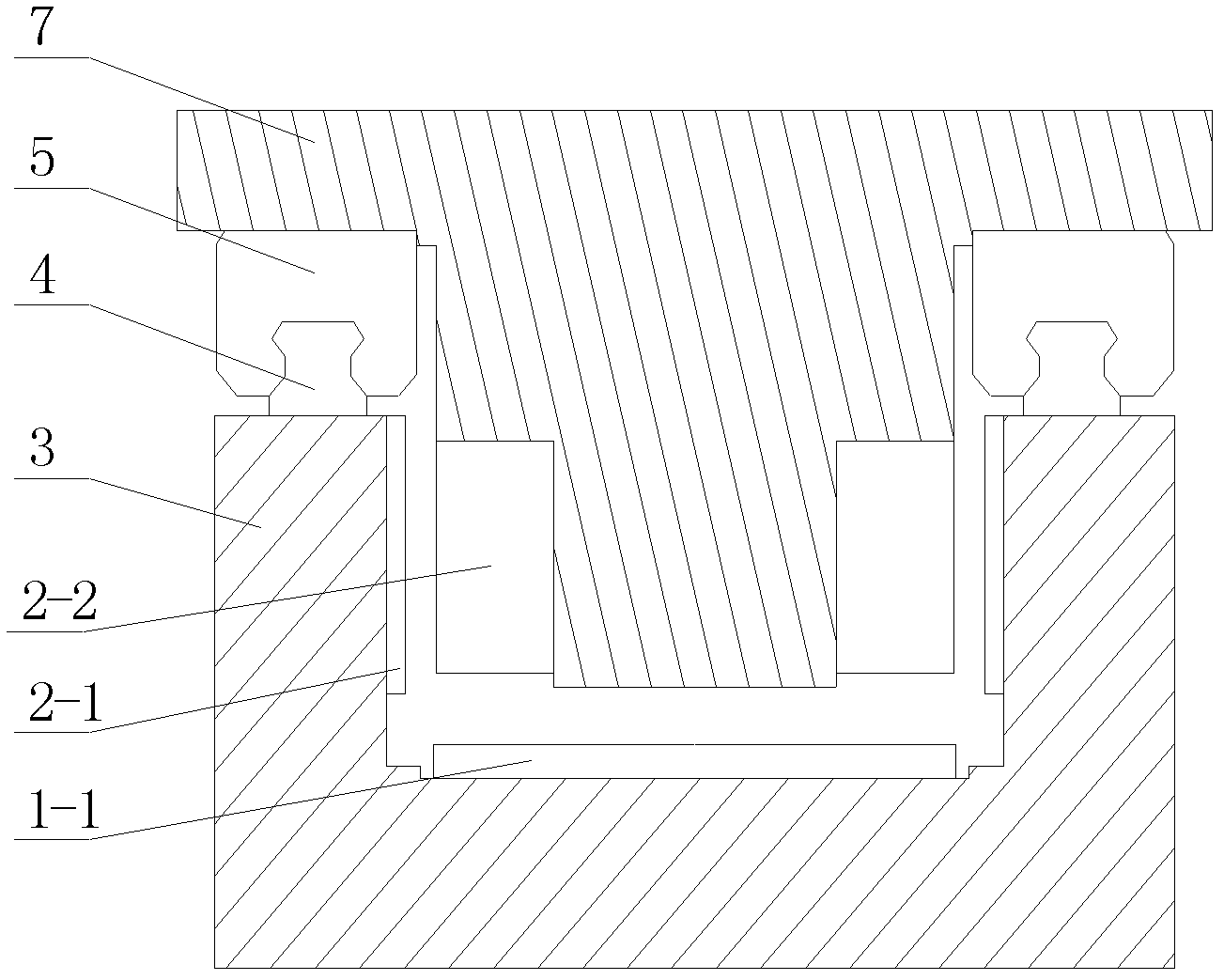

[0048] Specific implementation mode two: the following combination Figure 5 and Figure 6 Describe this embodiment, the dynamic braking type linear motor test loading device described in this embodiment includes a linear motor to be tested, and it also includes a linear brake for loading, a table body 3, a main support guide rail 4, and a sliding frame 6 for the motor under test , load brake carriage 7, force sensor and displacement sensor,

[0049] The upper surface of the table body 3 is symmetrically provided with a main rail substrate 3-1, and the main rail substrate 3-1 divides the upper surface of the table body 3 into a left section, a middle section and a right section,

[0050] The main support rails 4 are arranged symmetrically on the upper surface of a pair of main rail substrates 3-1, the tested motor sliding frame 6 and the loading brake sliding frame 7 are all arranged on the main supporting rails 4, and the measured motor sliding frame 6 passes through the mai...

specific Embodiment approach 3

[0056] Specific implementation mode three: the following combination Figure 7 and Figure 8 Describe this embodiment. This embodiment is a further description of Embodiment 2. The test loading device described in this embodiment also includes an auxiliary support guide rail 8 and an auxiliary guide rail slider 9. The table body 3 also includes a pair of auxiliary guide rail substrates. 3-2,

[0057] A pair of auxiliary guide rail substrates 3-2 are arranged symmetrically on both sides of the table body 3, the auxiliary guide rail substrate 3-2 is parallel to the main guide rail substrate 3-1, and on the upper surface of the pair of auxiliary guide rail substrates 3-2 Auxiliary support guide rails 8 are arranged symmetrically, and the auxiliary support guide rails 8 are slidably connected with the loading brake sliding frame 7 through the auxiliary guide rail sliders 9 .

[0058] In this embodiment, an auxiliary guide rail base plate 3 - 2 is added to support the loading bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com