Automatic intercepting device of logistic sorting track

An automatic interception and track technology, applied in sorting, conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, aging structure, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

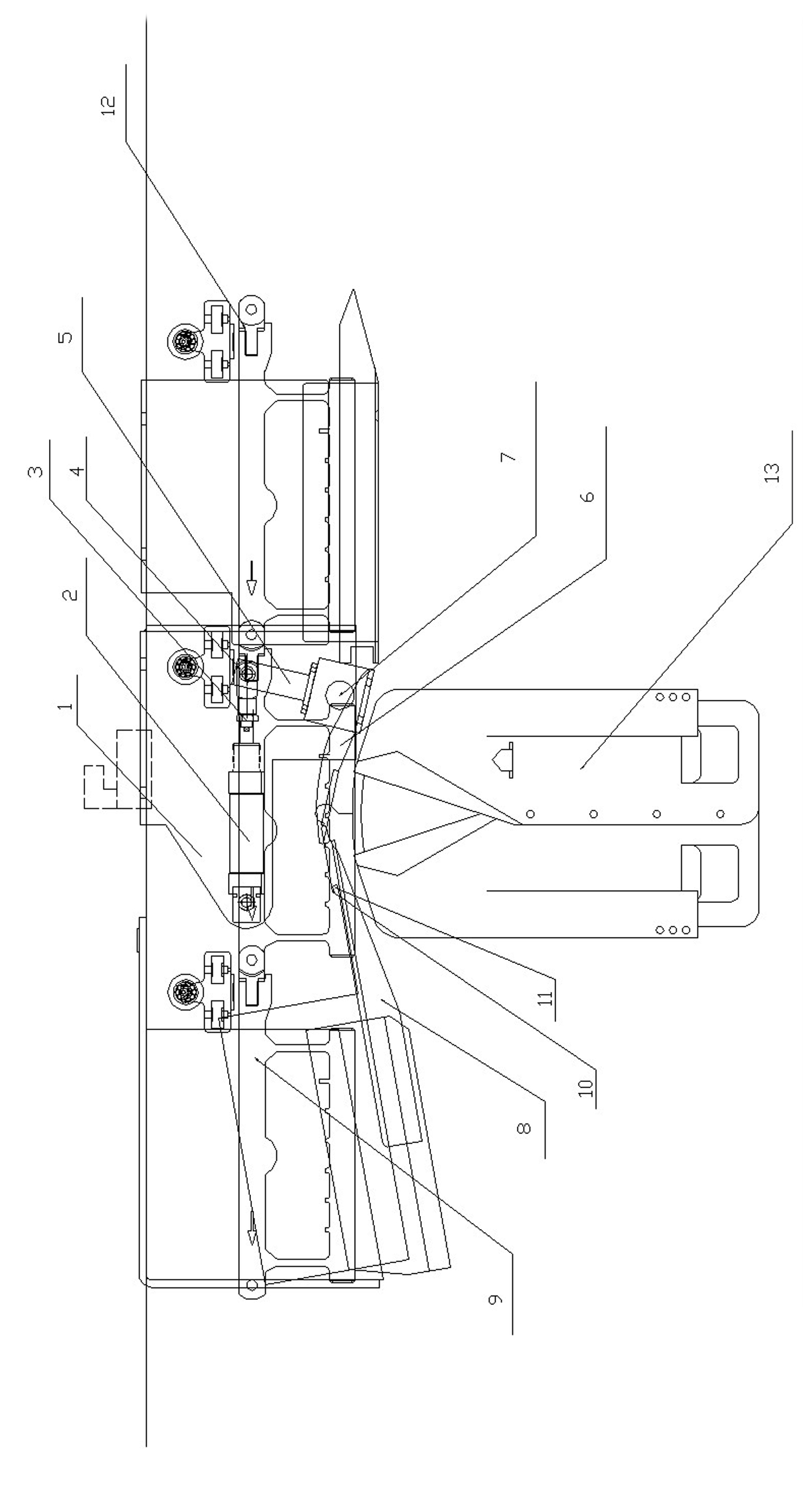

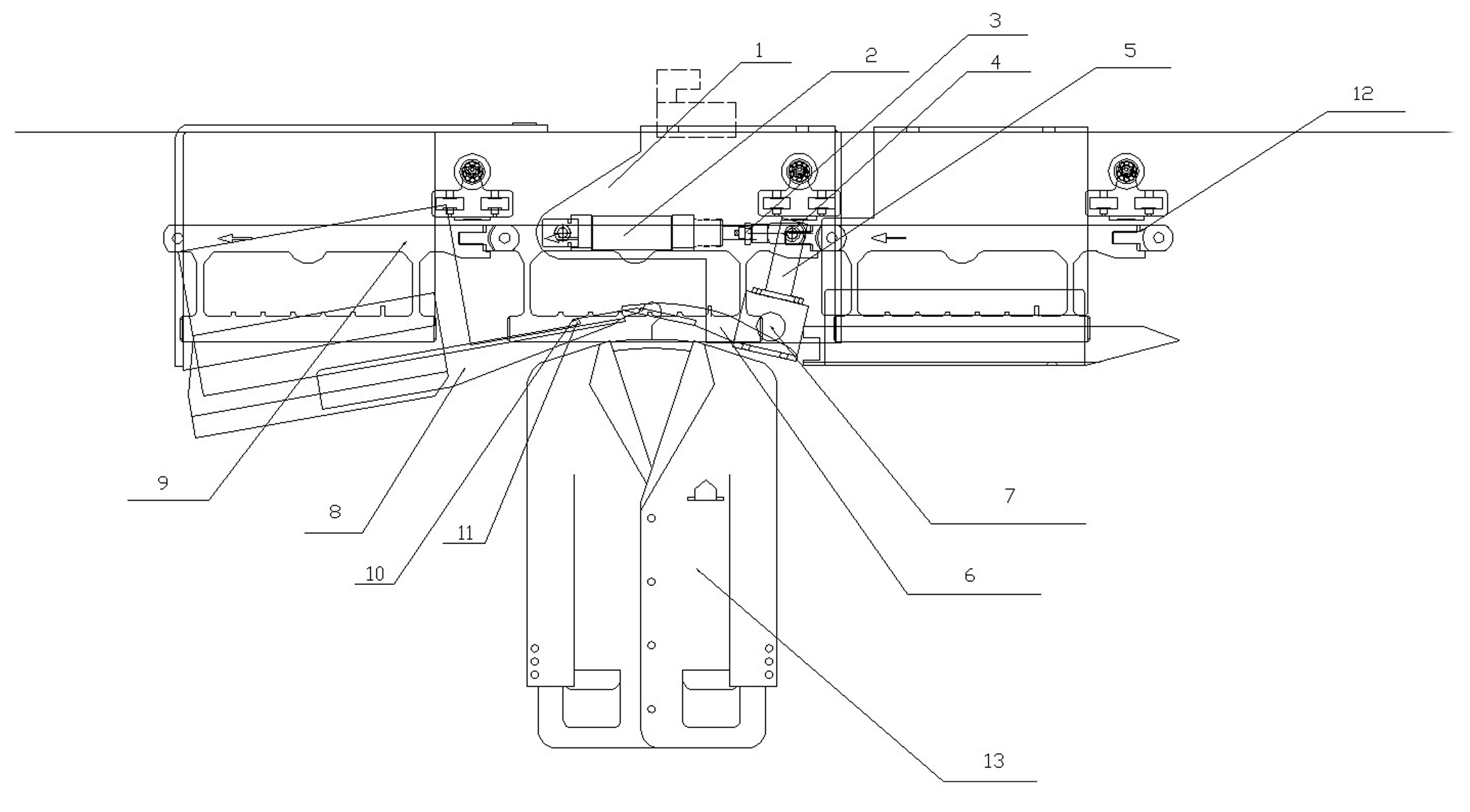

[0008] The invention is an automatic interception device for logistics sorting track, such as figure 1 As shown in , it mainly includes a bracket 1, which is different from the prior art in that: the bracket 1 is provided with a cylinder 2, the output shaft 3 of the cylinder 2 is movably connected with one end of the rocker lever 5 through a movable joint 4, and the rocker lever The other end of 5 is connected to one end of the clothes picker 6, the rocker arm 5 is provided with a fixed shaft 7 near the other end, the support 1 is provided with a clothes picker 8, and one end of the clothes picker 8 is set close to the other end of the picker 6 , one end of the clothes pick-up bar 8 is located obliquely above the other end of the clothes pick-up bar 6 (when the clothes pick-up bar picks up clothes and exceeds the height of the clothes pick-up bar, it is now above the clothes pick-up bar, and the clothes hanger rises along the clothes pick-up bar , go to the top of the clothes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com