Water/air separator

An air separator and separator technology, applied in separation methods, dispersed particle separation, combustion air/combustion-air treatment, etc., can solve problems such as performance degradation, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

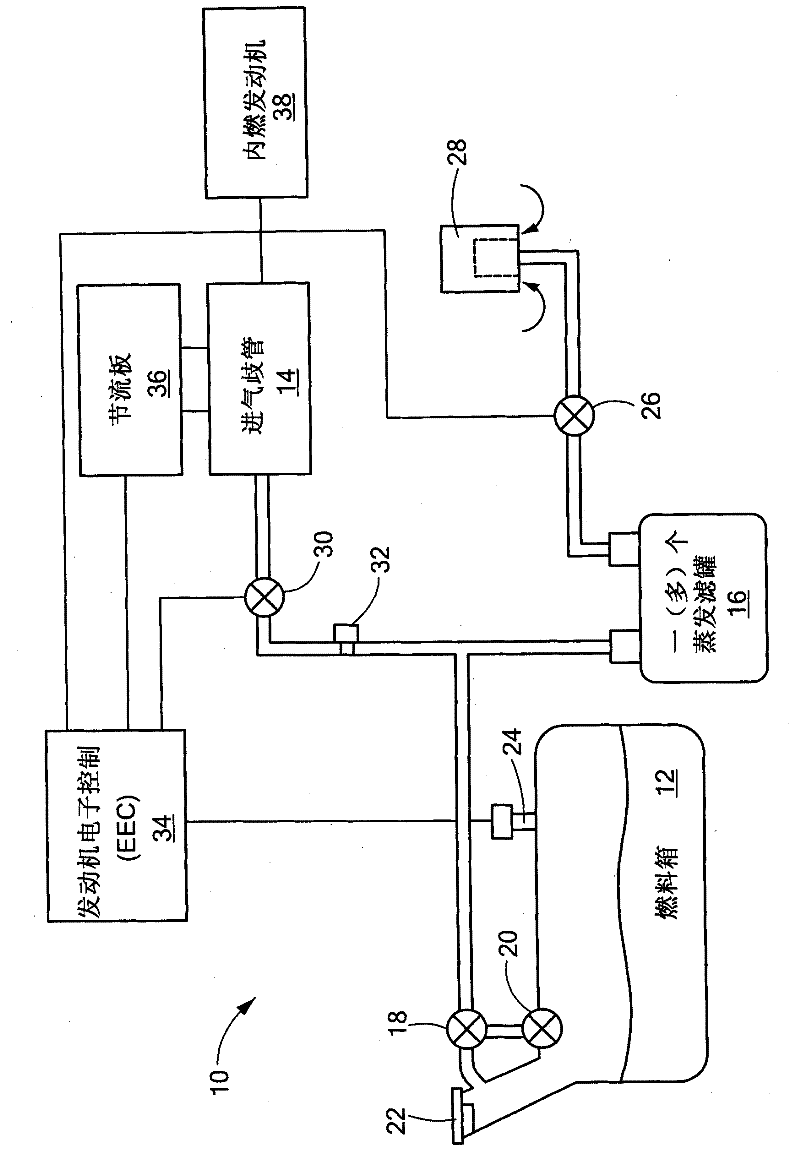

[0035] first reference figure 1 , the vehicle is equipped with an evaporative (fuel vapor) emission control system, generally indicated by the number 10. Emission control system 10 includes a fuel tank 12 having an upper interior volume in communication with one or more evaporative canisters 16 and an intake manifold 14 of an internal combustion engine (ICE) 38 . Fuel tank 12 provides fuel to engine 38 and generally includes vapor discharge valve 18 and rollover valve 20 . The fuel tank 12 may also include a vacuum relief valve 22 integral with the fuel tank cap for preventing excessive vacuum or pressure from being applied to the fuel tank 12 . The fuel tank 12 also includes a pressure sensor 24 for monitoring fuel tank pressure or vacuum and for providing a corresponding input signal to an engine electronic control (EEC) 34 . The pressure sensor 24 may be mounted directly into the fuel tank 12 or remotely mounted and connected to the fuel tank 12 by wire.

[0036] A vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com