Remote-controlled continuous zoom lens with liquid

A remote control and zoom lens technology, applied in the field of micro-optics, can solve the problems of high process difficulty, control accuracy and reliability limitations, complex production of liquid zoom lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in further detail below through embodiments and in conjunction with the accompanying drawings.

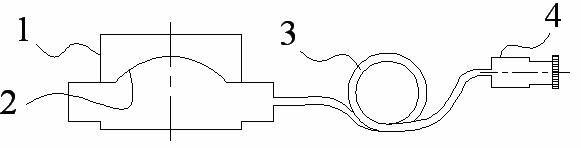

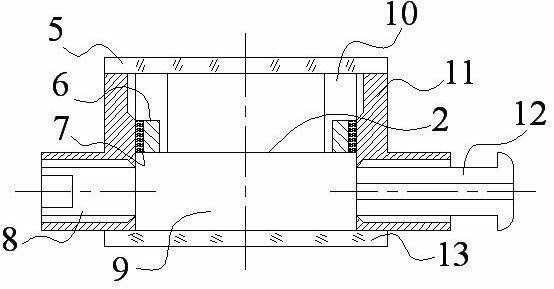

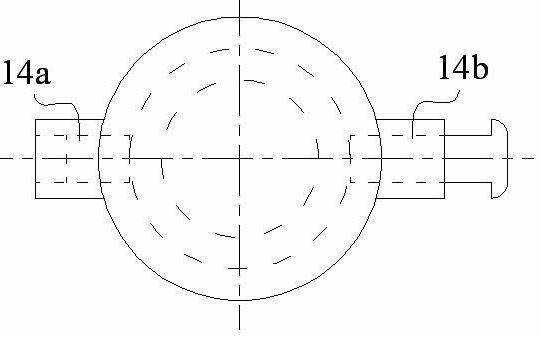

[0033] like figure 1 , 2 , 3, the remote control type liquid continuous zoom lens is composed of a zoom assembly 1, a hollow rubber tube 3 and a control assembly 4; Plate 13, the upper cover plate and the lower cover plate are all made of optical glass or plexiglass transparent material, the upper cover plate, the lower cover plate and the main body are bonded by glue; the main body is composed of an inner sleeve 10 and an outer sleeve 11, and the outer wall of the inner sleeve Threads are provided on the top, and threads are provided on the inner wall of the outer casing. The two are connected by thread fit. The outside of the inner casing is stepped. 2 Set on the lower end surface of the inner sleeve and pressed by the sealing ring 6 on the lower end surface of the inner sleeve 10, a chamber 9 is formed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com