Stage lighting system for improving uniformity of light spots

A lighting technology, uniformity technology, applied in electric light sources, components of lighting devices, devices used in theaters and circuses, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

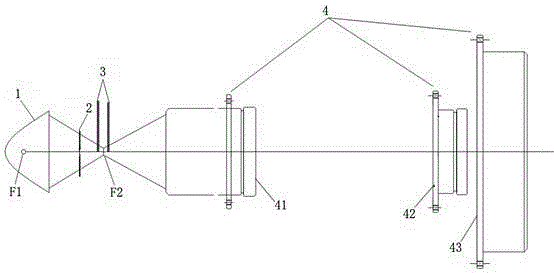

[0045] Such as figure 1 As shown, a stage light optical system for improving spot uniformity includes a light source arranged in sequence along the main optical axis, a reflector 1 and a second optical assembly 4, wherein the stage light optical system also includes a light source arranged on the reflector 1 The first optical component 2 between the first focal point F1 and the second focal point F2, the first optical component 2 is a single array lens.

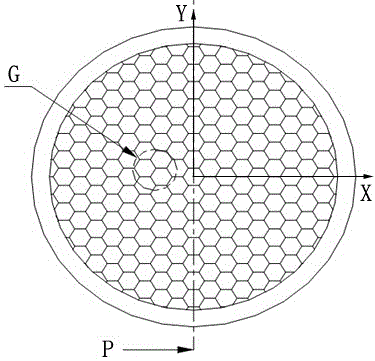

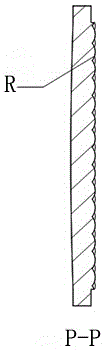

[0046] Such as Figure 2-4As shown, the structure of the array lens is based on glass, and the lens unit is covered on the glass plane. The lens unit is a convex lens unit. The longitudinal section of the lens unit is a regular polygon, preferably a regular hexagon or square. The lens unit mirror surface curvature The same or different, and each lens unit is closely connected together, and the adjacent lens units are seamlessly bonded. The array lens can divide the entire light beam into thin beams and re-superimpose, so th...

Embodiment 2

[0074] In this embodiment, the first optical component is improved on the basis of embodiment 1, and the rest of the structure is the same as that of embodiment 1.

[0075] Such as Figure 9 As shown, the first optical component described in this embodiment is a combination of an array lens and a lens, specifically, it includes a first convex lens 51, a first array lens 21, a second array lens 22, and a second array lens arranged in sequence along the main optical axis. Two convex lenses 52.

[0076] Similarly, the first optical component may also be an array lens and a combination of array lenses, that is, it is composed of several array lenses arranged in sequence along the main optical axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com