Axial gap rotating electrical machine

A technology of axial gap and rotating motor, which is applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the problems of improving and not being able to benefit the performance of rotating motors, and reduce manufacturing costs. The effect of reducing the number of assembly steps and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

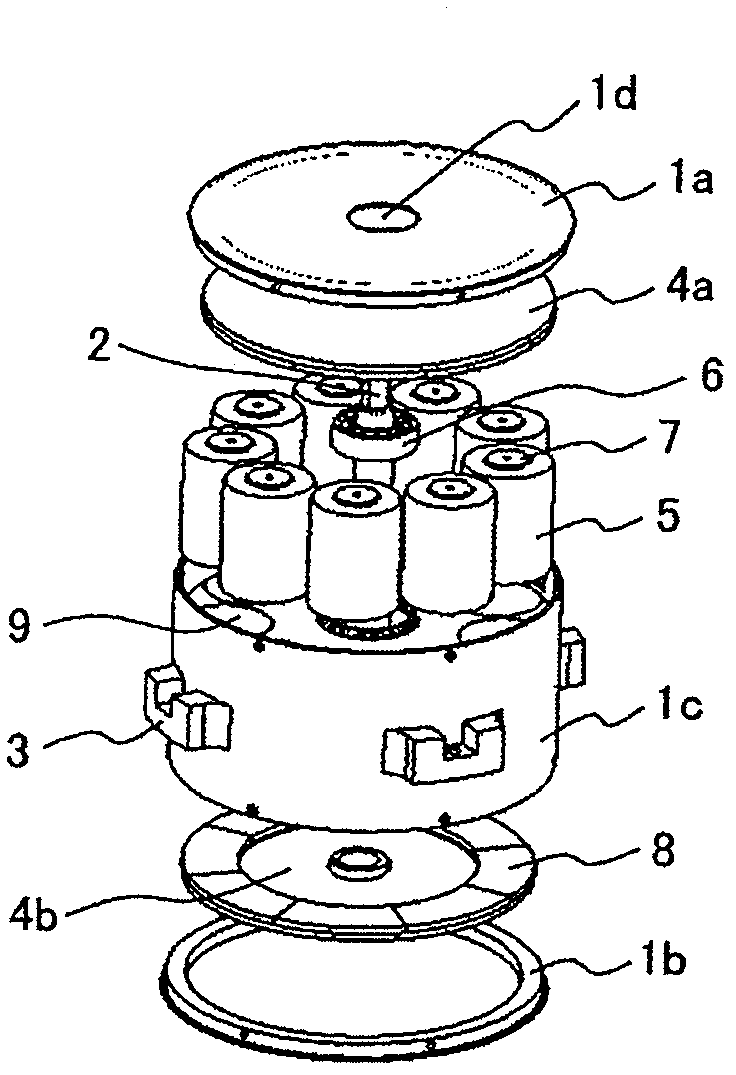

[0068] Hereinafter, embodiments of the present invention will be described using the drawings. Here, an axial gap motor will be described as an example of the axial gap type rotating electric machine of the present invention, but the structure described below can also be used as a generator instead of a motor.

[0069] 【Example】

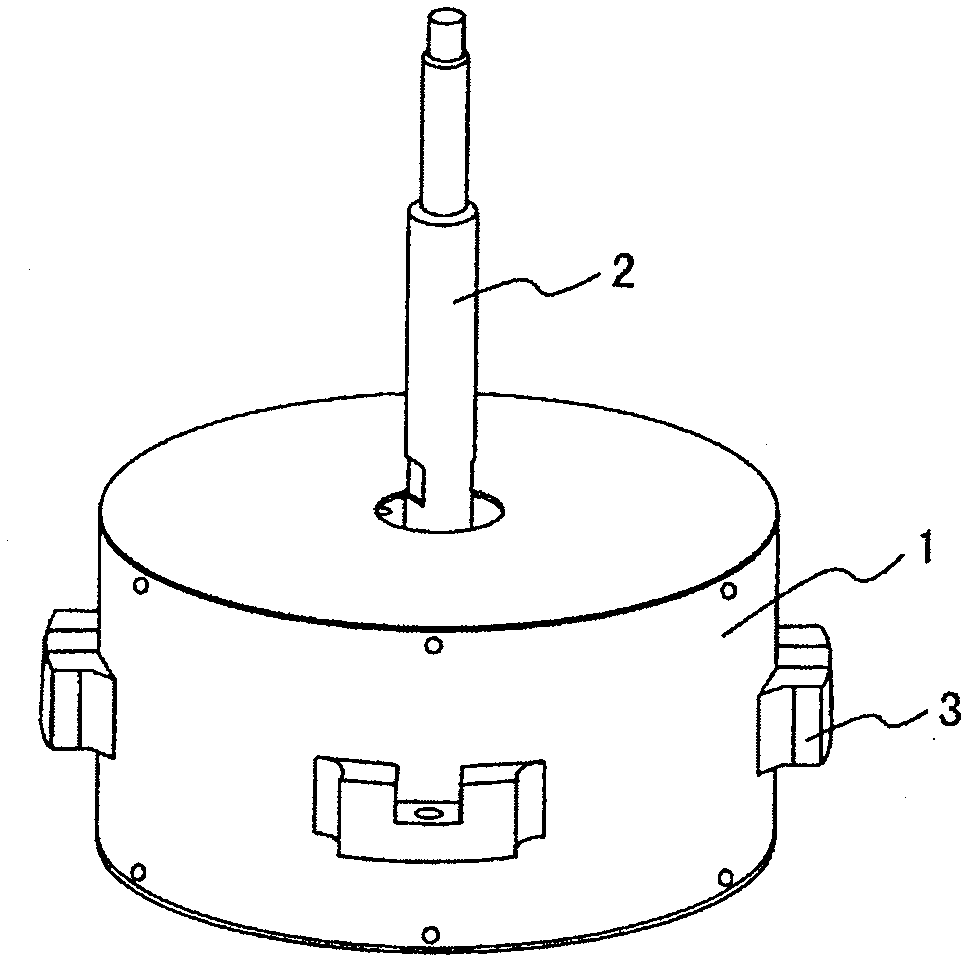

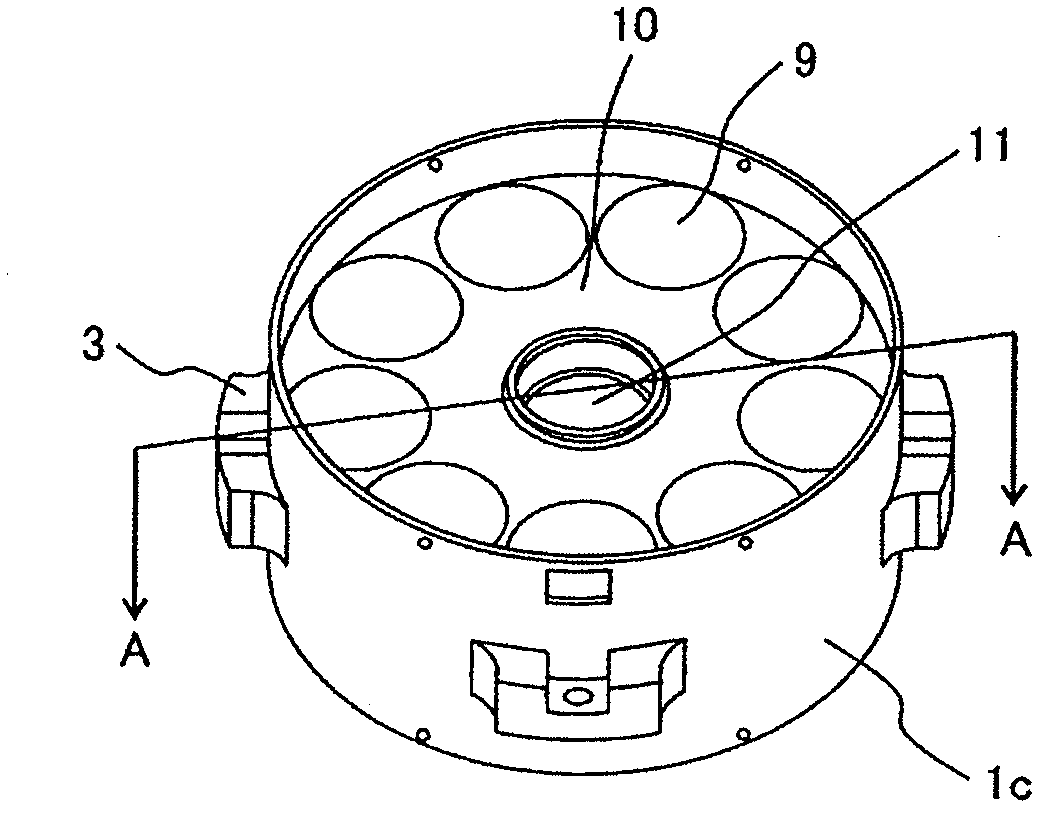

[0070] figure 2 It is a diagram showing the external shape of a general axial gap type rotating electrical machine, and has a shaft 2 extending upward in the center of a substantially cylindrical rotating electrical machine case 1 made of a non-magnetic material. The shaft 2 can be taken out from both sides of the casing 1 of the electric rotating machine, and an example of taking out only one side is shown here.

[0071] It should be noted that the rotating electrical machine housing 1 is provided with a mounting portion 3 for fixing the rotating electrical machine. In addition, as for the material of the case 1, when it is applied to a motor, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com