Method for preventing pressure peaks in a working medium cycle having a hydrodynamic machine

A working medium, hydraulic machine technology, applied in the direction of hydraulic brakes, hydraulic resistance brakes, mechanical equipment, etc., can solve problems such as equipment and control inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

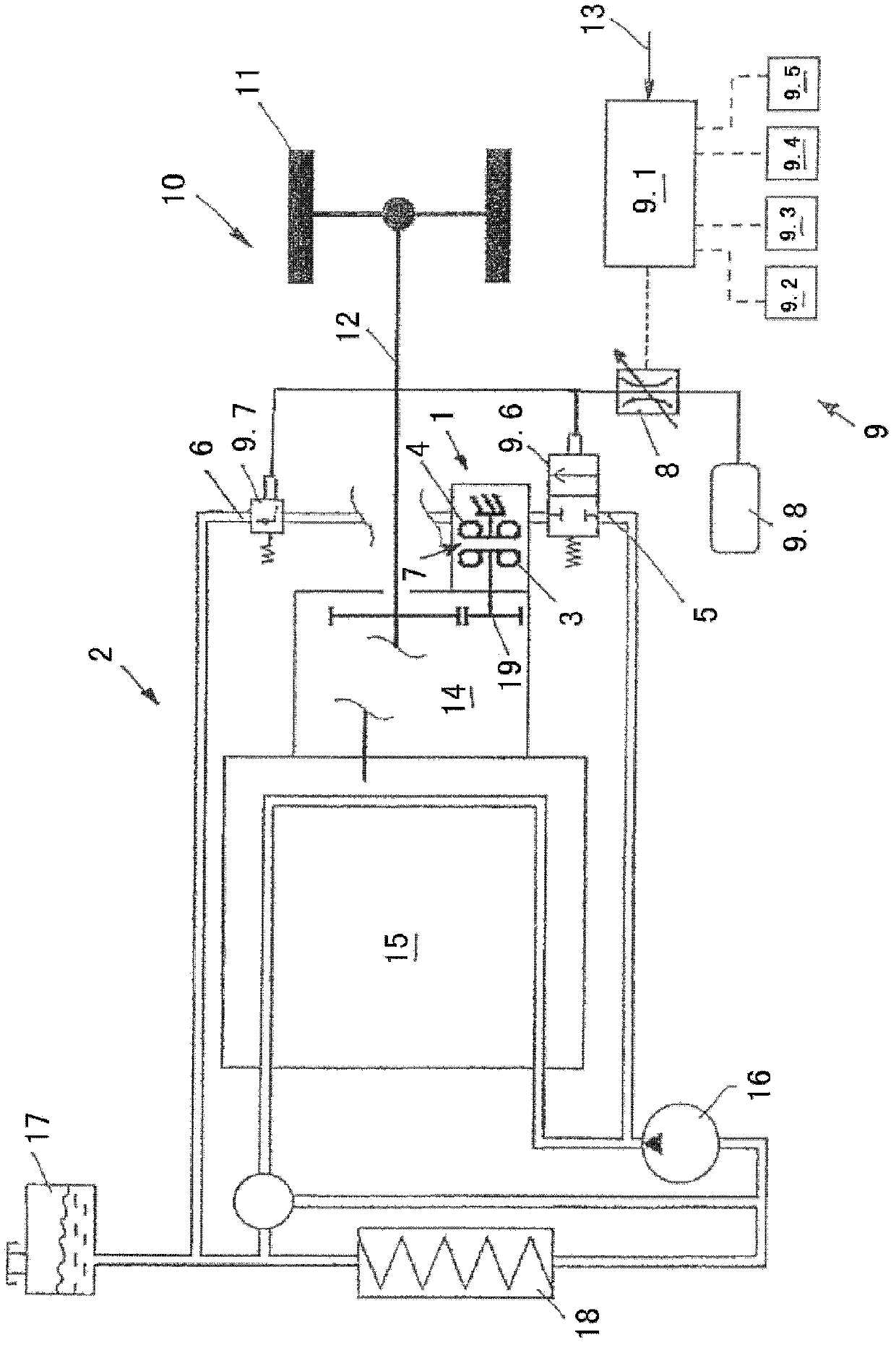

[0023] figure 1 A drive train 10 of a motor vehicle with an external working medium circuit 2 is shown. In this case, the working medium circuit 2 represents the cooling circuit. Furthermore, the hydraulic machine 1 , in this case a hydraulic retarder, is arranged in the external working medium circuit 2 , the retarder being arranged in this case as a water stop, so that its working medium also represents the vehicle at the same time. The cooling medium of the cooling circuit.

[0024] From the flow direction of the fluid, the following components are arranged in the working medium circuit 2 after the retarder: valve 9.7, hole for compensating adjustment tank 17, heat exchanger 18, circulation pump 16 and another valve 9.6. In this case, the valve 9 . 7 is arranged in the working medium circuit 2 in the region of the working medium outlet 6 and the valve 9 . 6 is arranged in the working medium circuit 2 in the region of the working medium inlet 5 . The internal combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com