Rolling method used for rolling strip steel of reversible mill

A rolling mill and strip technology, which is applied in the rolling field of strip steel in reversible rolling mills, can solve the problems of over-thick strip thickness, ultra-thin strip thickness, and reduce the yield of strip steel, so as to shorten the out-of-tolerance length. , The effect of improving product yield and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

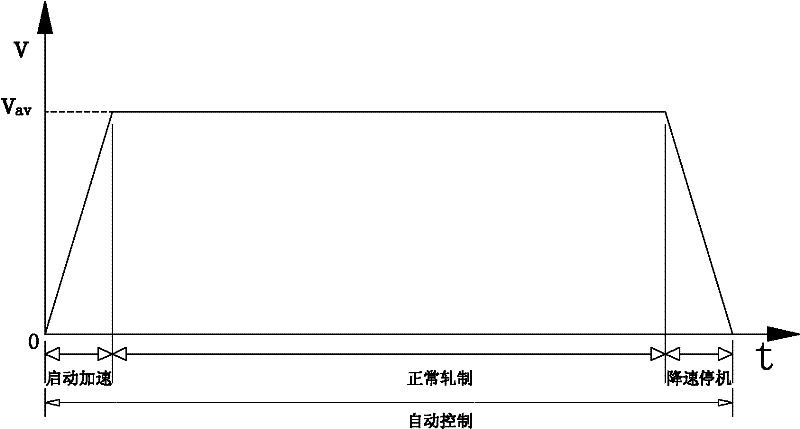

[0023] In the first step, after the strip threading is completed, the automatic strip thickness control function of the reversing mill is turned off, the reversing mill is started, rolling is carried out at a speed of 12m / min, and the pressure is adjusted manually to control the strip thickness deviation after rolling. 0~2.5% range.

[0024] In the second step, when the manual adjustment of the strip thickness accuracy reaches the range of 0 to 2.5%, the automatic control function of the strip thickness of the reversible rolling mill is turned on, and the rolling speed of the reversible rolling mill is accelerated to reach the normal rolling speed of 600m / min. The thickness deviation of the rear strip is controlled within ±1%.

[0025] Table 1 below shows the length of the thickness tolerance section of the same type of non-oriented electrical steel before and after rolling by the above-mentioned method of the present invention.

[0026] Table 1

[0027]

Embodiment 2

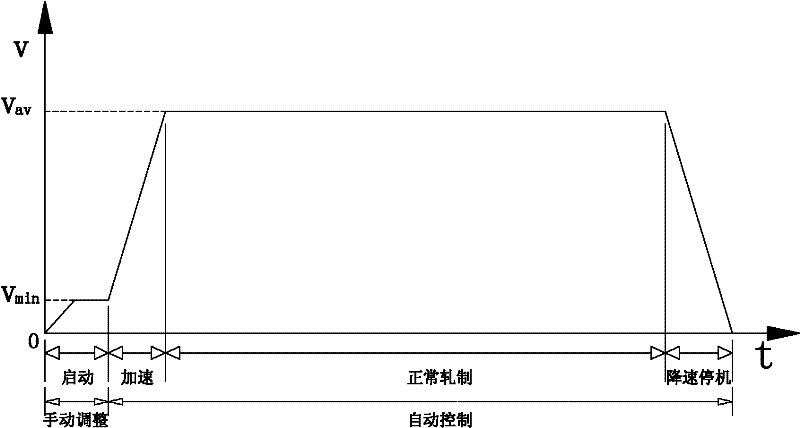

[0029] In the first step, after the strip threading is completed, the automatic strip thickness control function of the reversing mill is turned off, the reversing mill is started, rolling is carried out at a speed of 12m / min, and the rolling mill is manually adjusted to control the strip thickness deviation after rolling. In the range of -1.5 to 3%.

[0030] In the second step, when the accuracy of the strip thickness is manually adjusted to -1.5 to 3%, the automatic control function of the strip thickness of the reversible mill is turned on, and the rolling speed of the reversible mill is accelerated to reach the normal rolling speed of 800m / min. Strip thickness deviation is controlled within ±1%.

[0031]The length of the over-tolerance section of the thickness of the same type of non-oriented electrical steel rolled before and after the method of the present invention is shown in Table 2 below.

[0032] Table 2

[0033]

[0034] It can be seen that the length of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com