Automatic correcting error control on converter tilting angle

A technology of automatic deviation correction and control method, applied in the direction of manufacturing converters, etc., can solve the problems of angle error, encoder deviation, debugging difficulties, etc., to achieve the effect of eliminating deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

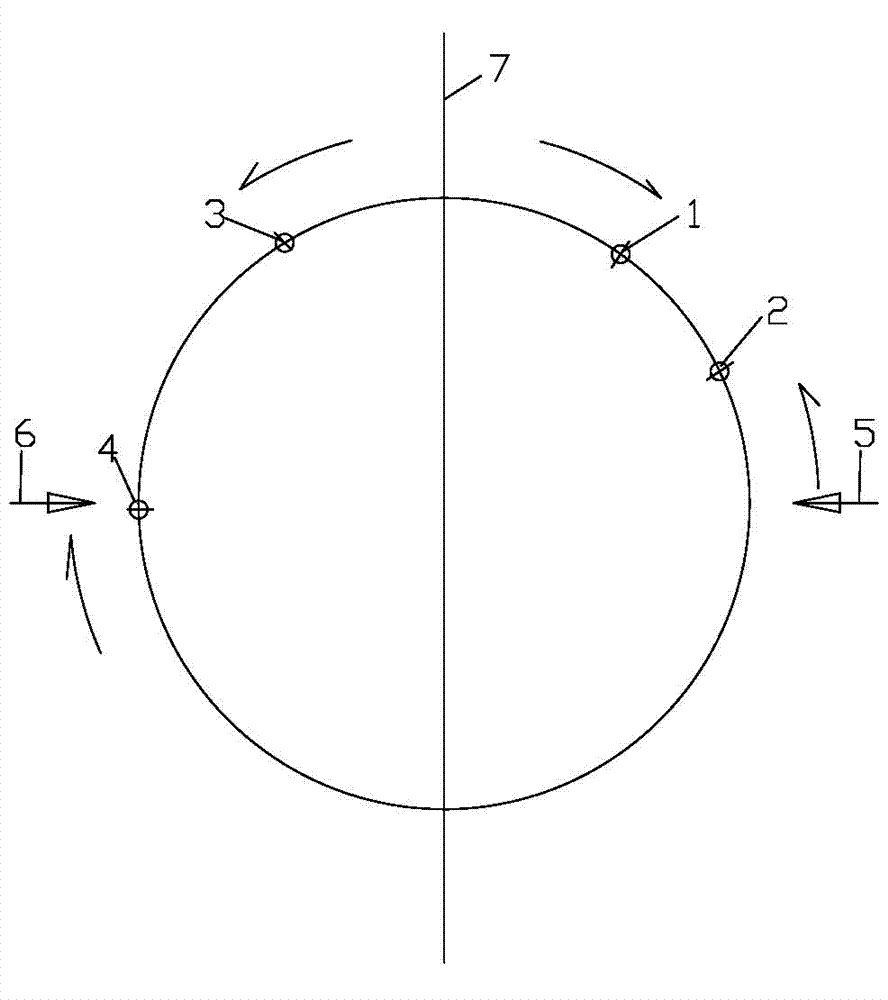

[0019] The automatic deviation correction control method of the converter tilting angle involved in the present invention includes PLC control, a rotary encoder and a master controller, the master controller is provided with 4 master controller control points, the first master controller Control point 1 is set in the area of 0~30 degrees when the converter rotates clockwise to the front of the furnace, the control point 2 of the second master controller is set in the area of 50~30 degrees when the converter rotates counterclockwise to the back of the furnace, and the third master controller Let the control point 3 of the controller be set in the area of 360~340 degrees after turning counterclockwise to the back of the furnace, and the control point 4 of the fourth main controller is set in the area of 270~300 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com