Throttling device

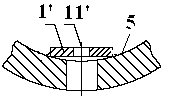

A technology of throttling device and throttling seat, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem that the throttling orifice 1' is easy to fall off, inconvenient to disassemble and replace, and the throttling function fails, etc. problems, to achieve the effect of enhancing the firmness and safety of the device, improving the installation accuracy, and avoiding wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with preferred embodiments, wherein the water bag 5 under the water wall of the boiler is taken as a specific embodiment of the pressure vessel 5 as an example.

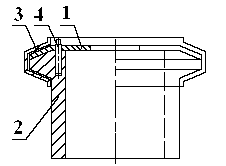

[0034] Such as Figure 4 and Figure 7 As shown, a throttle device includes a throttle orifice 1 , a throttle seat 2 , and a clamp ring 3 .

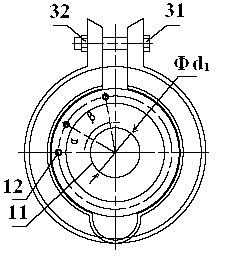

[0035] Throttle orifice 1 is provided with throttling holes 11 and N 1 A first pin hole 12, the orifice 11 is arranged in the center of the orifice plate 1, the diameter is Φd 1 , the first pin hole 12 is provided on the surface of the throttling orifice plate 1 and penetrates through the throttling orifice plate 1 .

[0036] Throttle seat 2 is a hollow column, such as Figure 2~Figure 4 As shown, the outer surface of the throttle seat 2 is smooth, and it is welded and connected with the water bag 5 under the water wall of the boiler. Its material is the same as that of the water bag 5 under the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com