Clearance and flatness measuring tool

A technology for measuring tools and gaps, which is used in mechanical gap measurement, mechanical roughness/irregularity measurement, etc. It can solve the problems of poor position consistency of gap and flatness measurement, large data fluctuation, and measurement tools that cannot measure gaps and flatness. , to achieve the effect of improving production efficiency and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

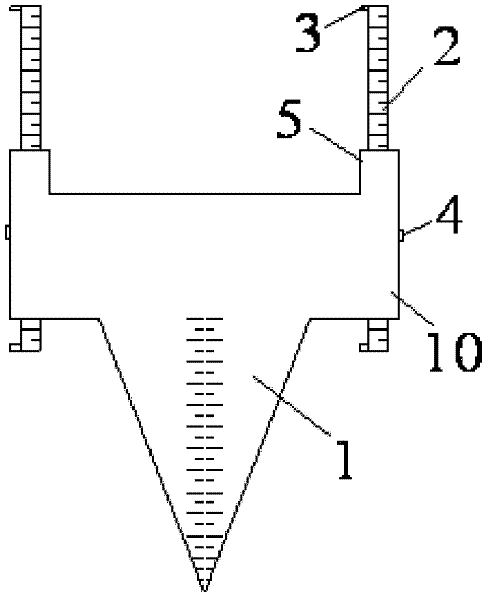

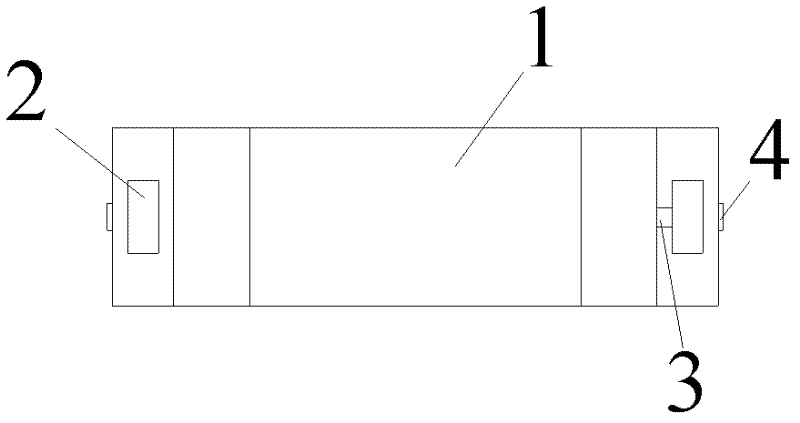

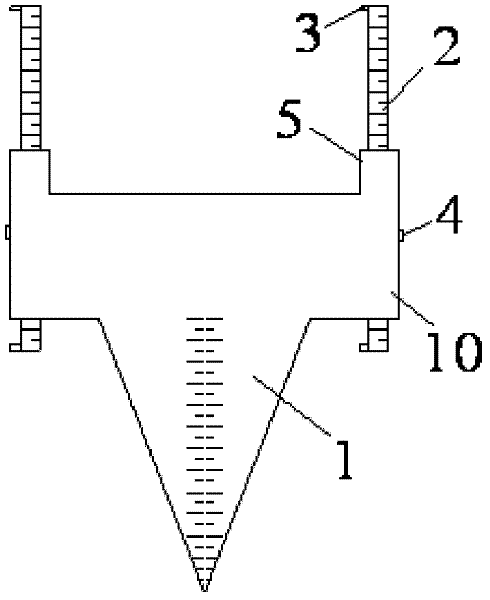

[0016] Such as figure 1 and figure 2 As shown, a gap and level measurement tool includes a tapered ruler 1 for gap measurement and a slide rule 2 for flatness measurement at the same time. The plane of the tapered ruler is an isosceles triangle, and a vertical scale line is arranged on the plane of the isosceles triangle, and the numerical value of the scale line is the width of the tapered ruler at the scale line. Said tapered ruler is symmetrically provided with a sliding ruler which can measure the flatness at the same time by the outer sides of the two waists of the isosceles triangle, and the sliding ruler and the tapered ruler carry out a clearance fit; specifically, the etc. A pair of side arms 10 are symmetrically arranged on the outer sides of the two waists of the waist triangle, and the slide rule 2 can slide vertically in the side arms 10 . The sliding rule is in the shape of a long ruler, and scale lines are arranged on the long ruler, and the sliding rules on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com