Uniaxially coupled double-wind driven generator

A wind-driven generator and single-axis technology, applied in the direction of wind-driven generator components, wind-driven engines, wind-driven motor combinations, etc., can solve problems such as inconvenience, large deflection force of the generator support frame, and inappropriate application of large-scale generators, etc., to achieve Easy to use, high heat dissipation efficiency, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

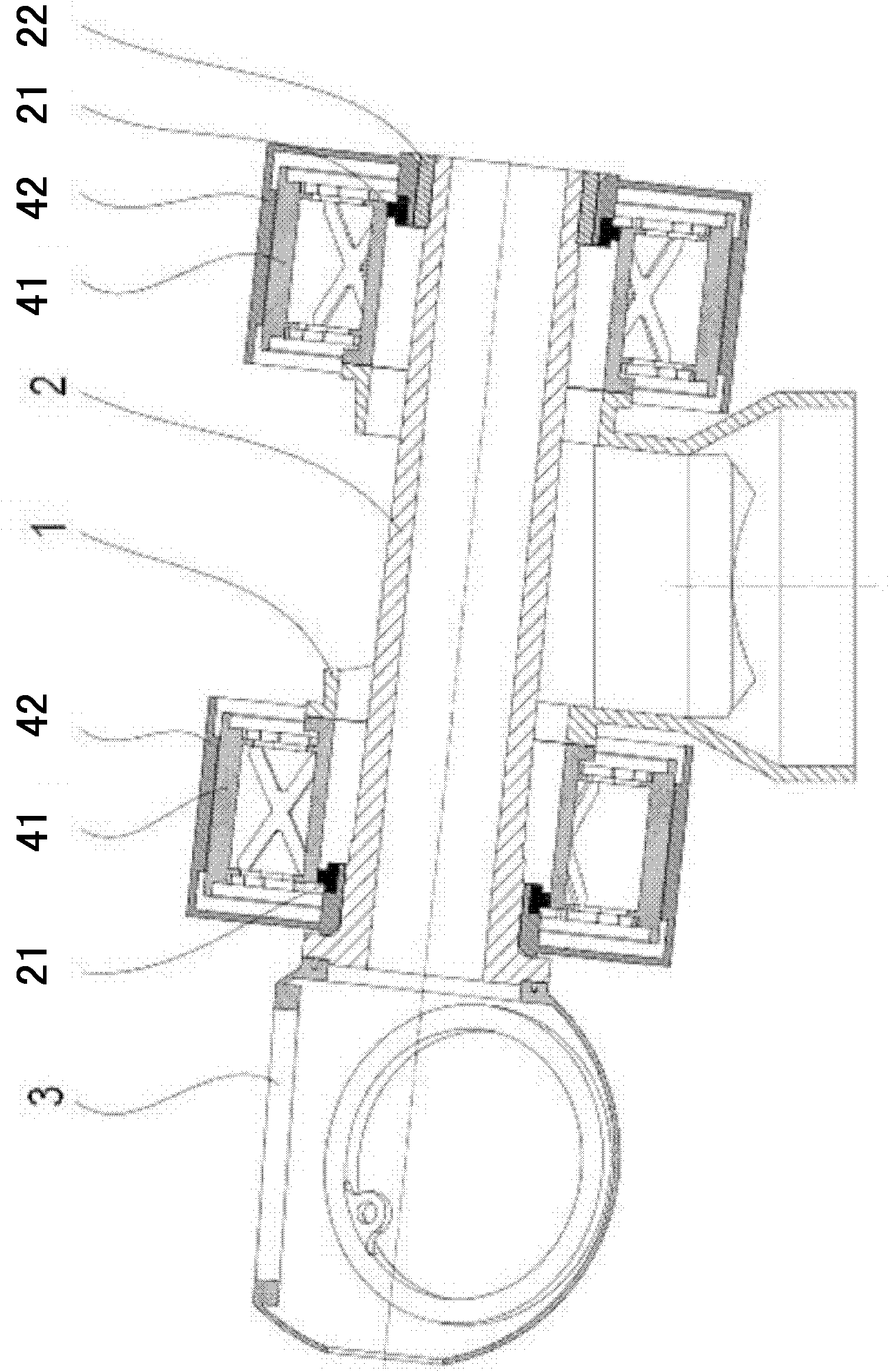

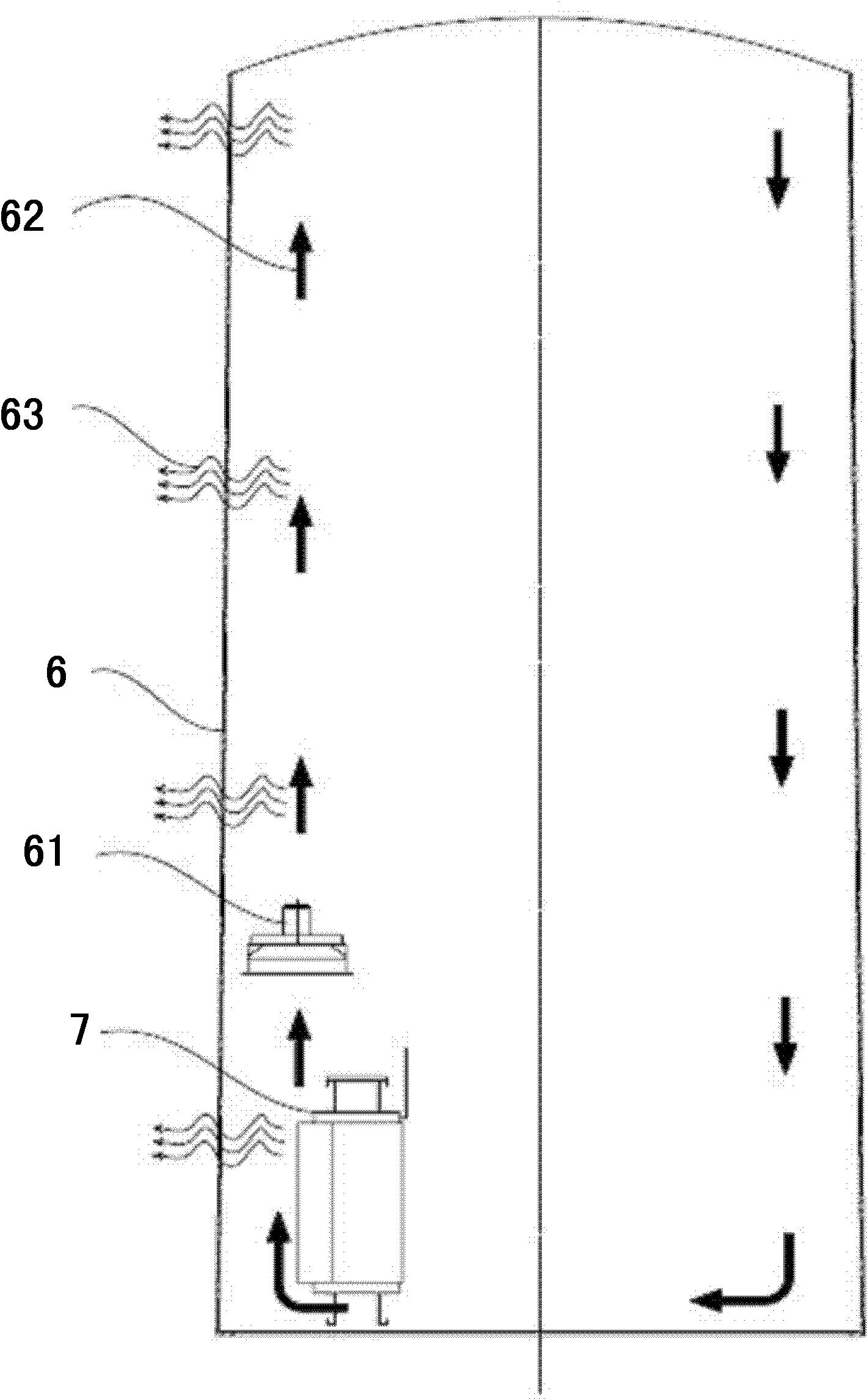

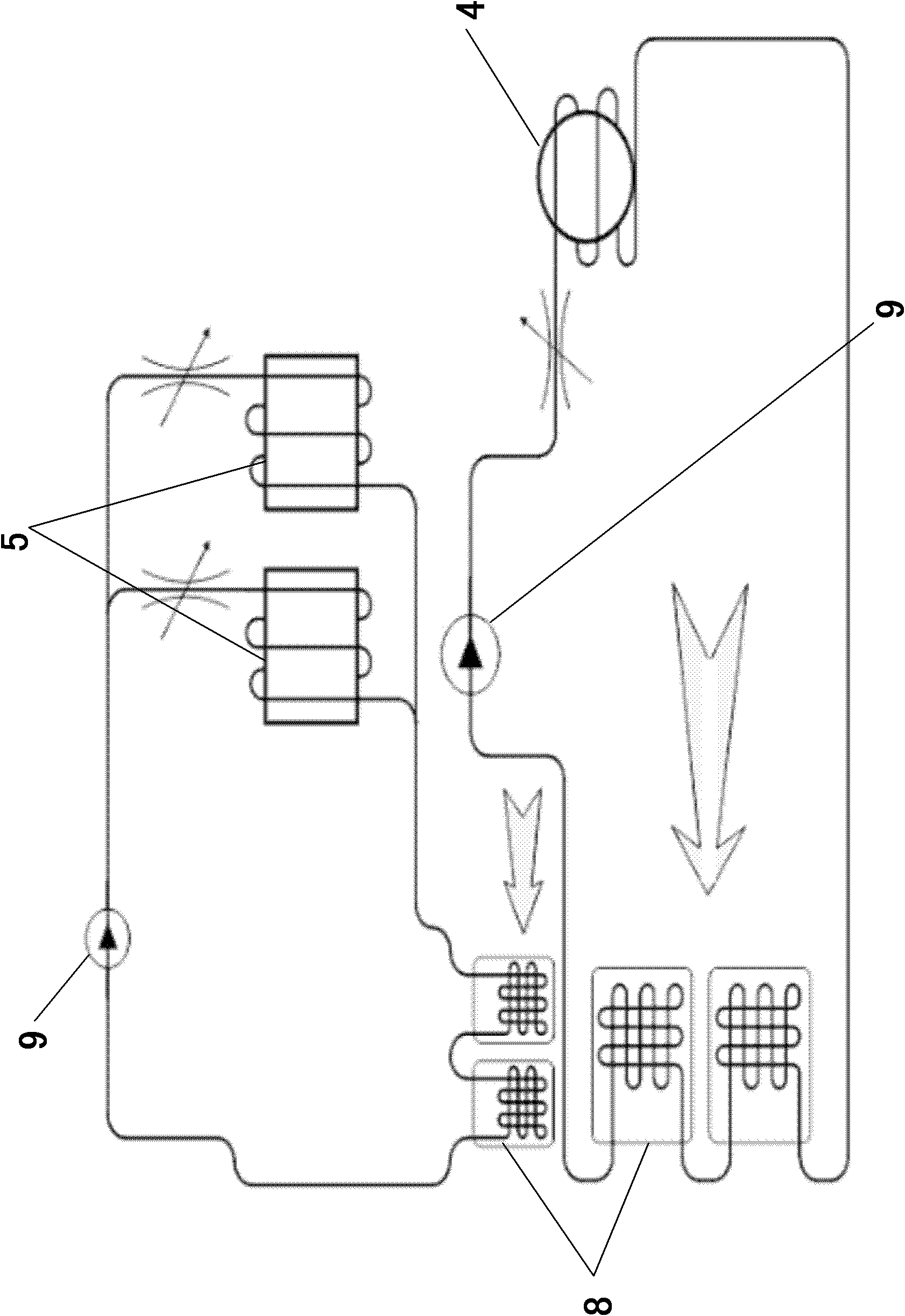

[0030] see figure 1 As shown, the single-shaft coupled dual wind power generator of the present invention mainly includes a tower 6 , a main frame 1 , a main shaft 2 , a hub 3 , a converter and two wind power generators 4 .

[0031] Among them, the two wind power generators 4 are medium voltage (MV) megawatt variable speed permanent magnet wind power generators, both of which are mainly composed of an inner stator 41 and an outer rotor 42 .

[0032] The stator 41 is preferably a coil winding made of rectangular copper conductors, forming multiple parallel circuits, using a three-phase system.

[0033] The rotor 42 is a permanent magnet, preferably a bipolar permanent magnet system. Each pole is connected by a plurality of magnetic steel blocks through clamps and interference rings. The outer surface of the magnetic steel blocks is provided with electroplating or epoxy anti-corrosion coating. A copper layer is provided between the anti-corrosion coatings of the magnetic steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com