Alternating current permanent magnet synchronous spindle motor for threading machine

A permanent magnet synchronous, spindle motor technology, applied in the direction of synchronous machine parts, etc., can solve the problems of affecting the working efficiency of tapping machines, complex structure and speed regulating mechanism, slow rotation of the rotating shaft, etc., to achieve easy promotion and use, wide range Effects of load adaptability and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

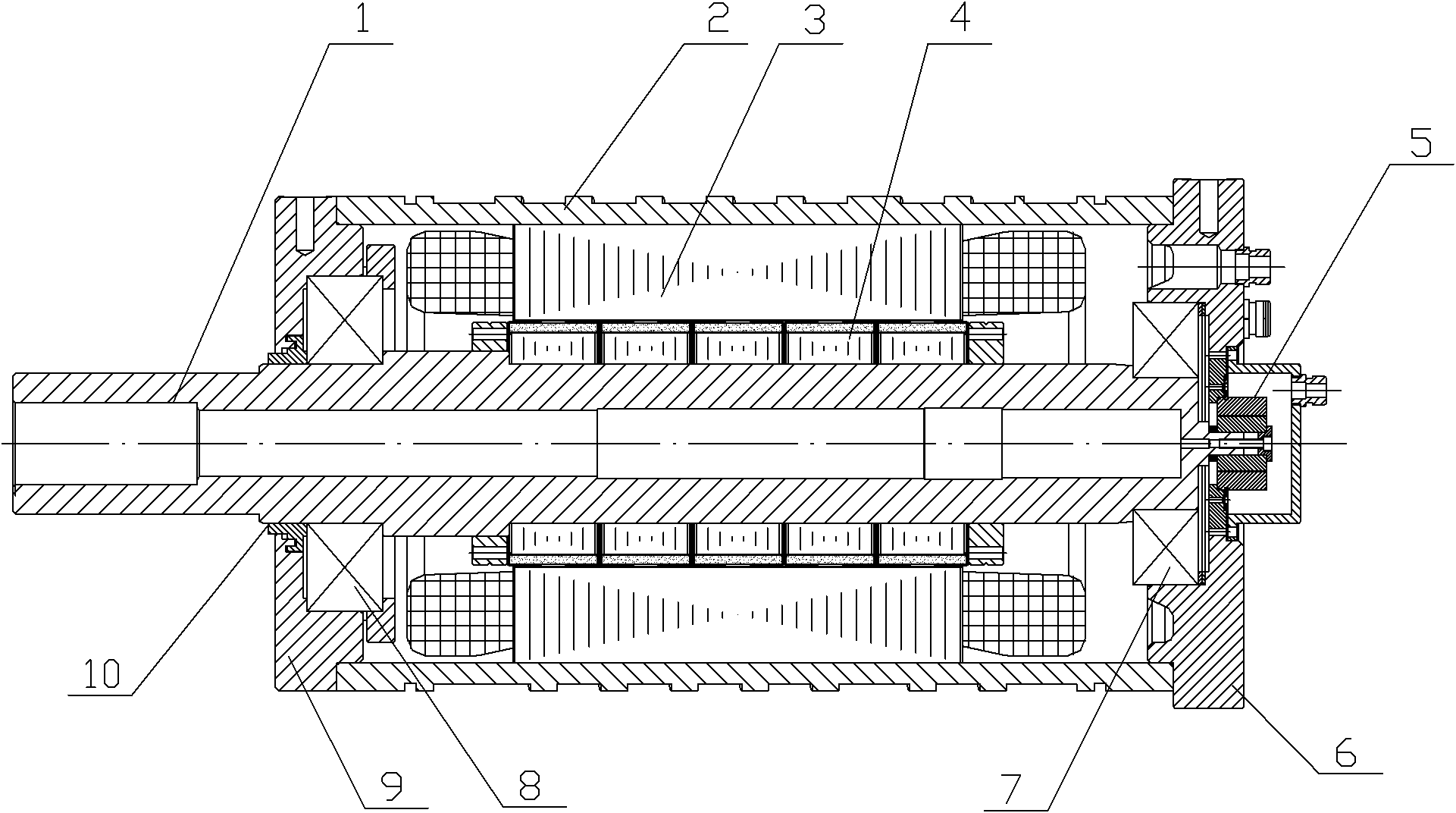

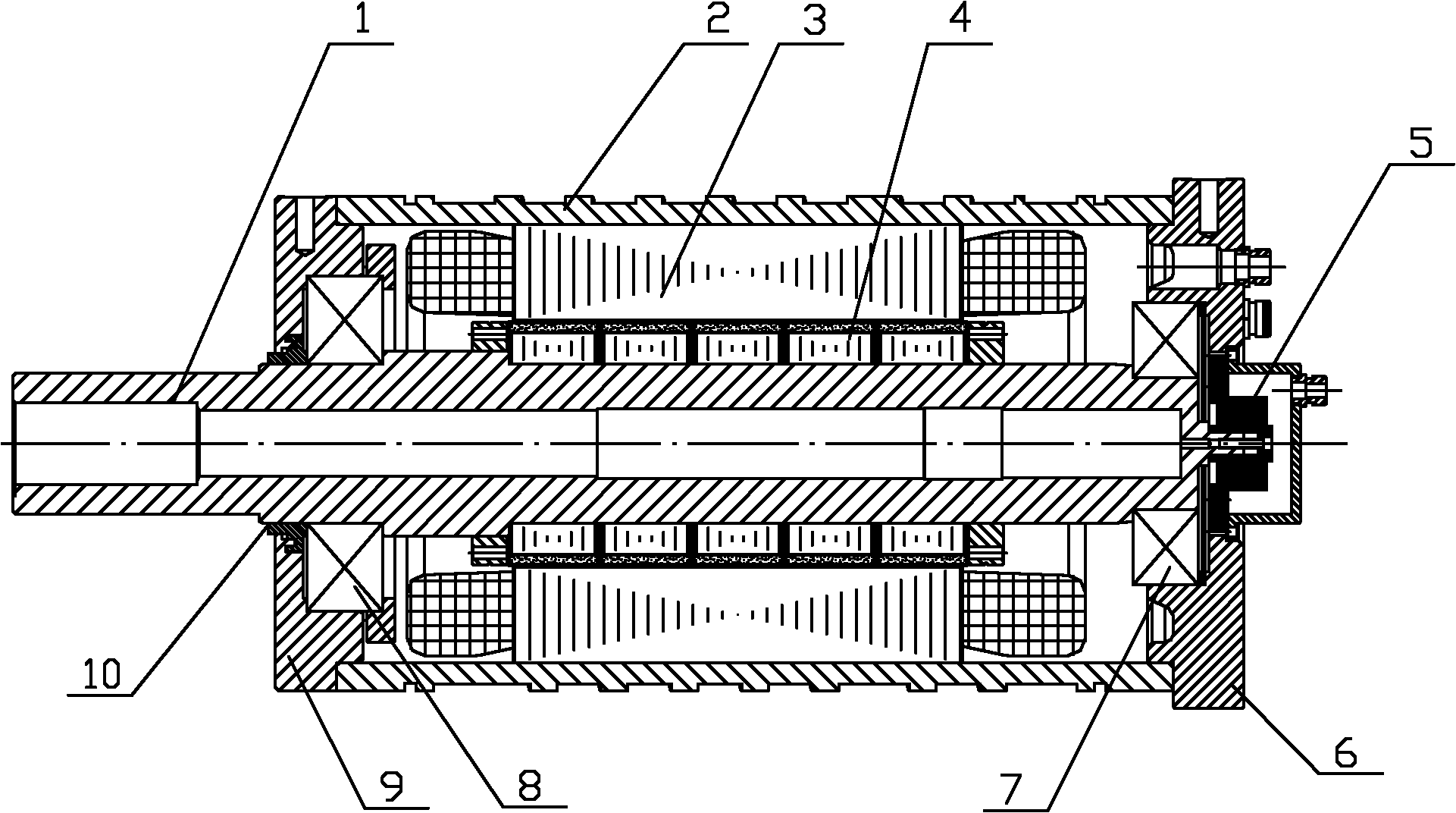

[0016] Such as figure 1 The shown AC permanent magnet synchronous spindle motor for tapping machine includes a housing 2, a rotating shaft 1, a permanent magnet rotor assembly 4, a stator assembly 3, an encoder 5, a front end cover 9 and a rear end cover 6. The front end cover 9 is installed on the front end of the casing 2, the rear end cover 6 is installed on the rear end of the casing 2, the rotating shaft 1 is arranged inside the casing 2 and is connected to the front end cover 9 and the The rear end cover 6 is connected, the permanent magnet rotor assembly 4 is installed on the rotating shaft 1, the stator assembly 3 is arranged on the inner wall of the housing 2 and corresponds to the permanent magnet rotor assembly 4, and the encoder 5 is installed on the rotating shaft The rear end of the shaft 1 and the encoder 5 are connected with an external driver, the rotating shaft 1 is a hollow structure, and the cross section of the hollow structure is variable. A sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com