Method for welding cylindrical shell of water heater

A welding method and water heater technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient pressure resistance, corrosion, water infiltration, etc., and achieve the effect of enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

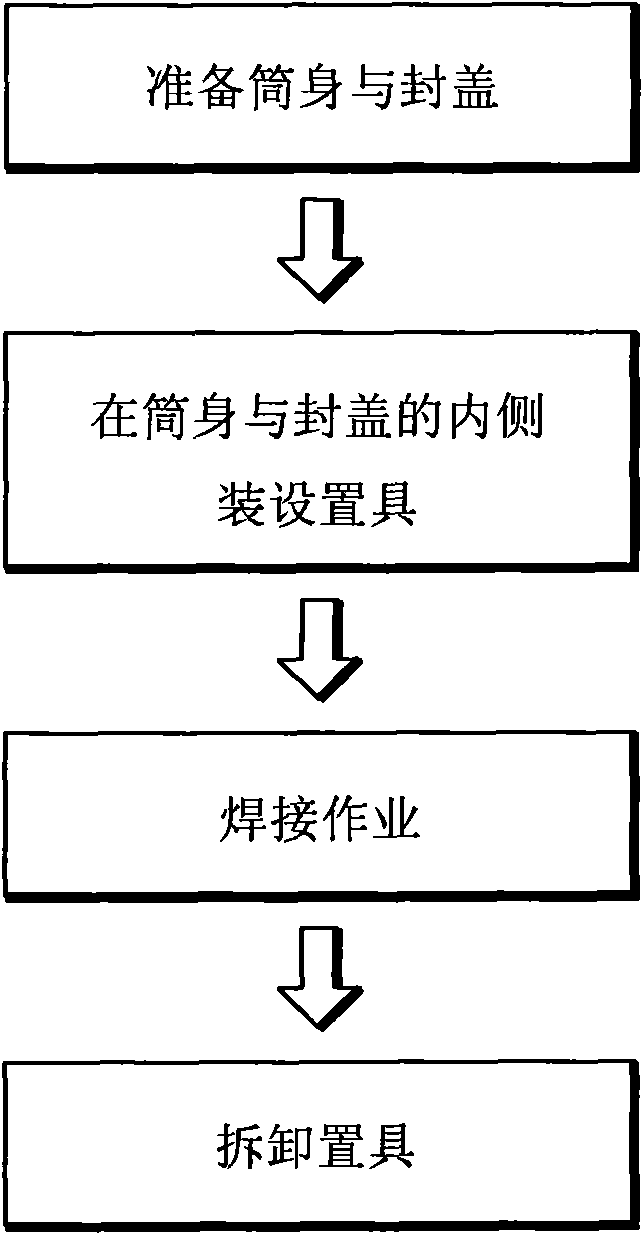

[0037] The invention provides a water heater cylinder welding method, such as Figure 1 to Figure 5 In the preferred embodiment shown, the steps of the welding method include:

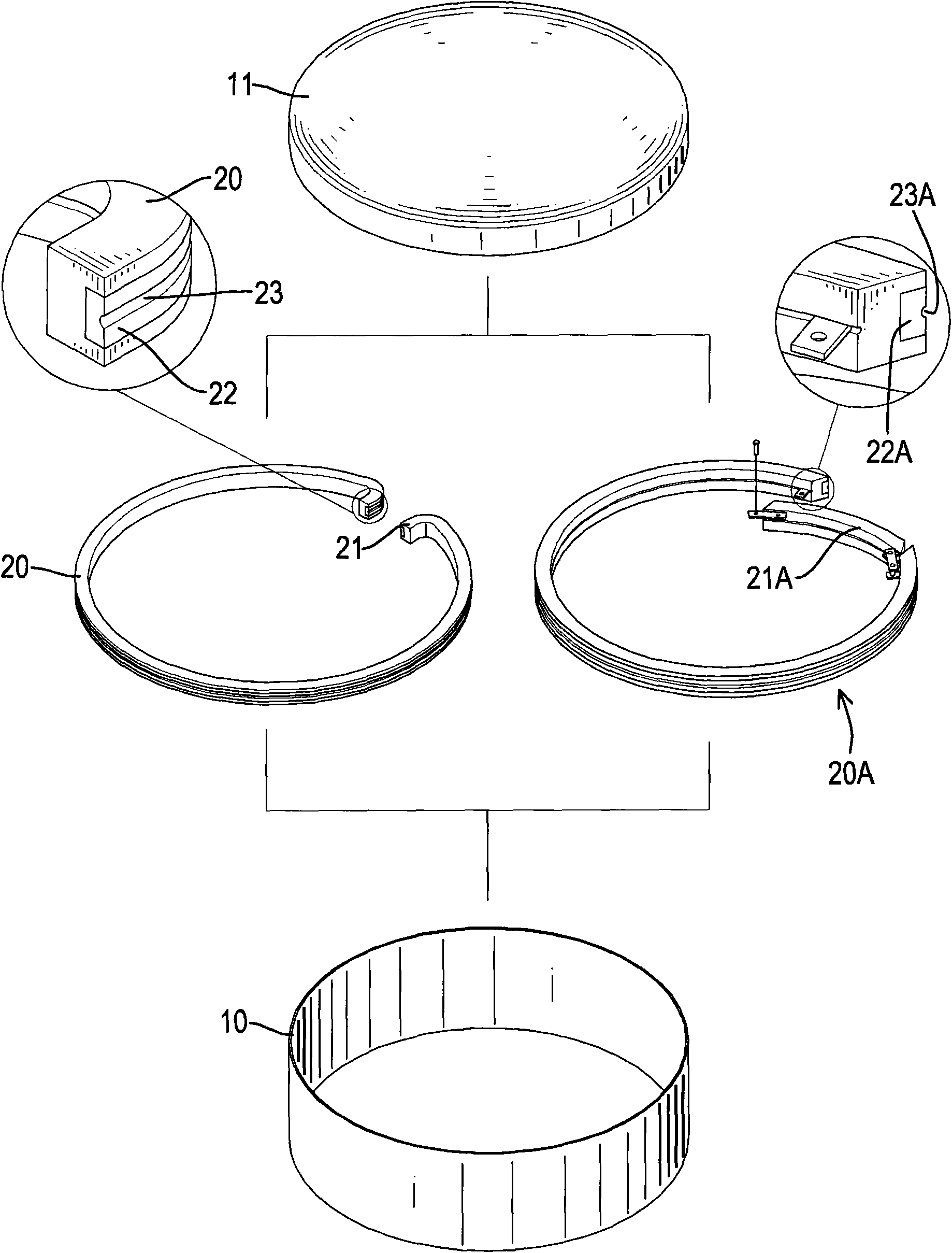

[0038] A. Prepare the cylinder body and cover: as figure 1 , figure 2 As shown, prepare a cylinder body 10 in the shape of a round tube and a cover 11 whose bottom edge matches the shape of the end edge of the cylinder body 10 , and connect the cover 11 to the end edge of the cylinder body 10 with the bottom edge.

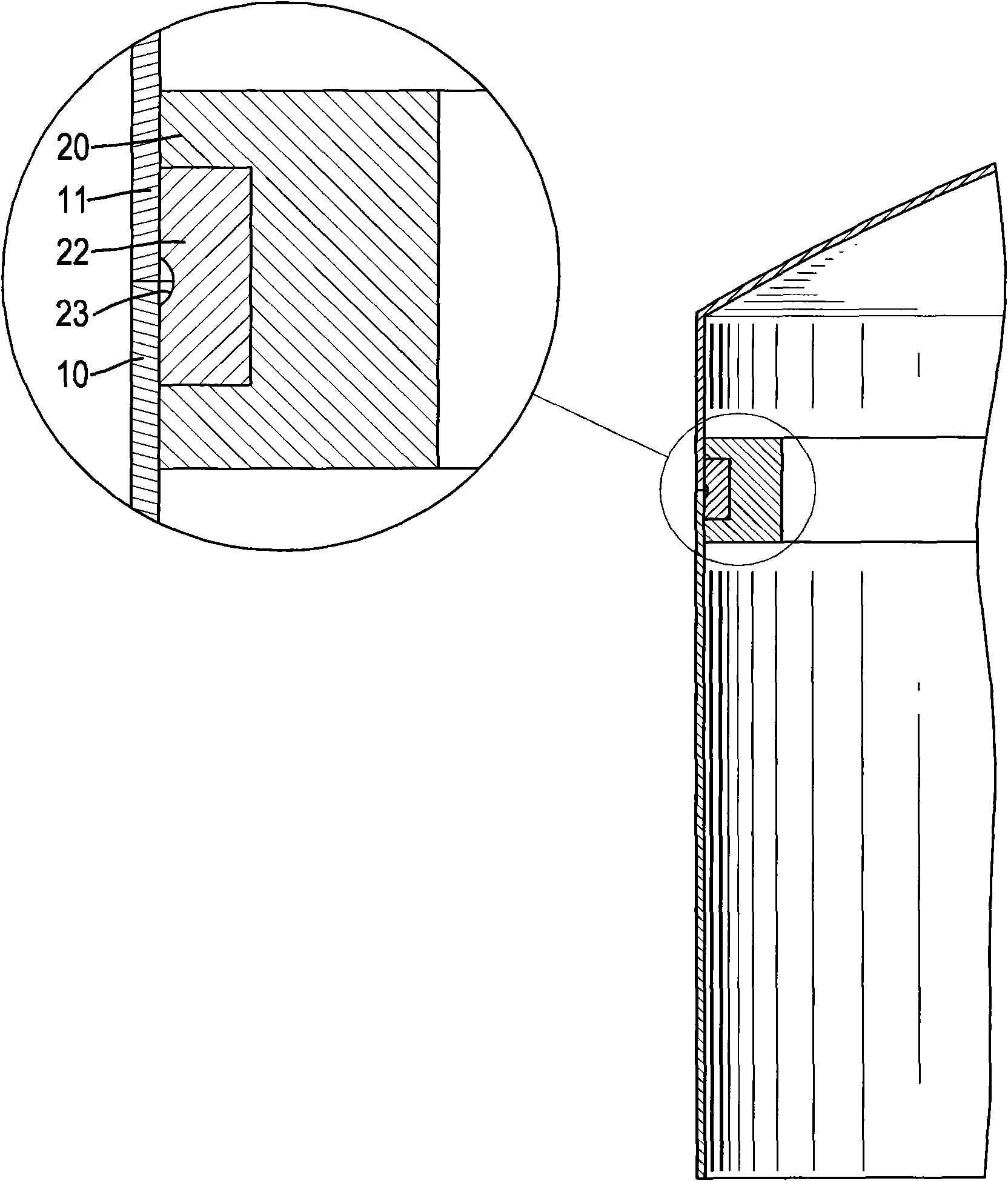

[0039] B. Install equipment on the inner side of the cylinder body and the cover: such as figure 1 , figure 2 As shown, on the inner surface of the end edge of the cylinder body 10 and the bottom edge of the cover 11, a set tool 20 is installed in a detachable form, which is a flexible C-shaped metal ring, which is bent inward at both ends. Stretch to form a clip part 21, a copper material 22 is embedded in the middle of the outer peripheral surface of the set tool 20, and a melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com