Tracklaying gear

A crawler mechanism and tensioning mechanism technology, which is applied in the field of crawler mechanisms, can solve the problems of complex tensioning devices and large sizes, and achieve the effects of making good use of available assembly space, saving assembly space, and flattening the damping curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

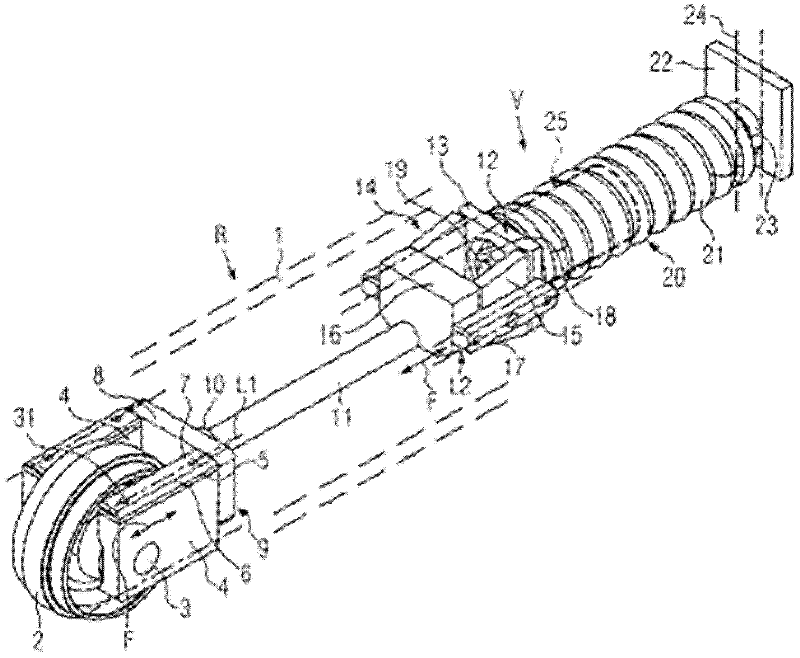

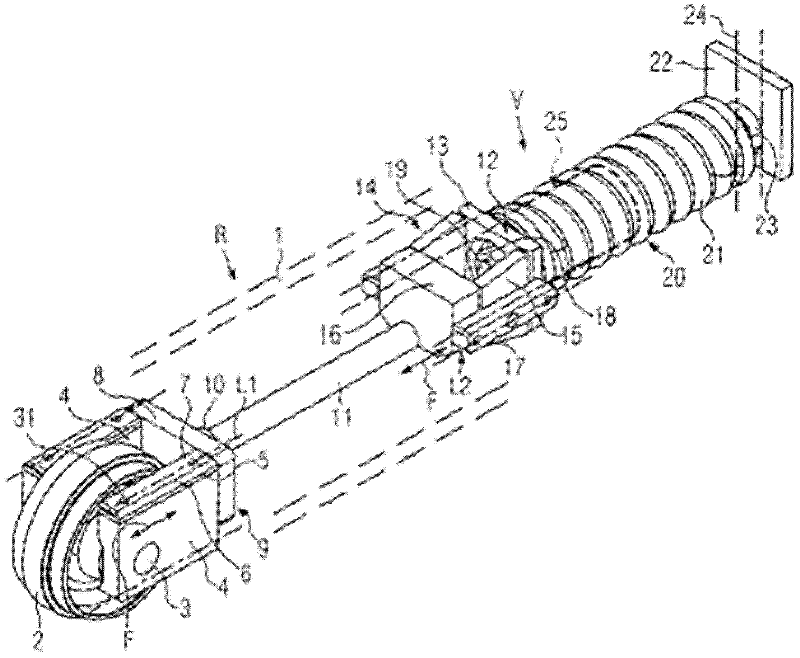

[0026] figure 1 Shown is a crawler mechanism R, particularly for construction machinery such as a road finisher (not shown), wherein the crawler mechanism R comprises a frame 1 (e.g. edge-mounted steel plates) on which besides tracks for not shown Track rollers and drag chain wheels, not shown, can also be provided with a drive guide wheel (not shown), wherein the track is guided on the guide wheel 2, which provides the track tensioning function in the track mechanism R And the tracks are pretensioned by the tensioning device V, but under impact loads under the force of the tensioning device V are recessed. As an alternative, two or more guide wheels 2 (not shown) placed next to each other can also be provided.

[0027] The guide wheel shaft 3 used in the guide wheel linear guide L1 of the frame 1 guides the guide wheel 2 displaceably in the guide direction F on two parallel block guides 4 here. Each guide 4 bears a sliding pad 6 at least on the upper and lower sides, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com