Air cylinder head for three-air-valve engine

A technology for engine cylinders and valves, applied to engine components, machines/engines, cylinders, etc., can solve the problems of poor airflow in the cooling air duct, unreasonable design of the cooling air duct, and air inability to flow out, etc., to achieve simple and reliable structure Increased durability and smooth air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

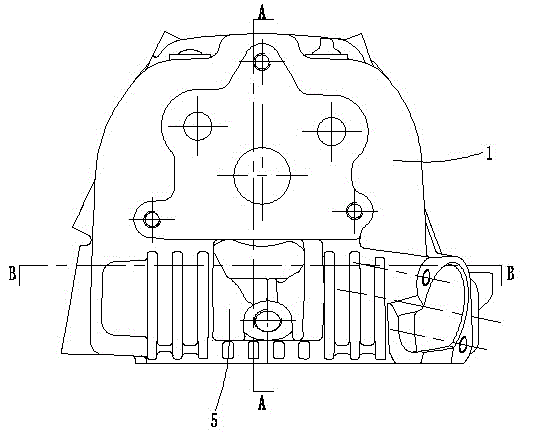

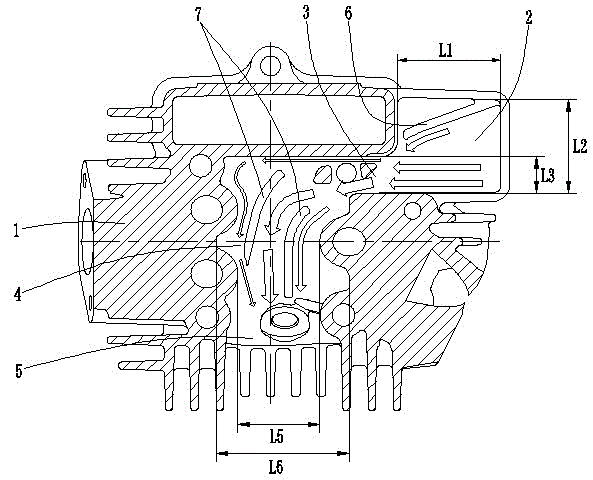

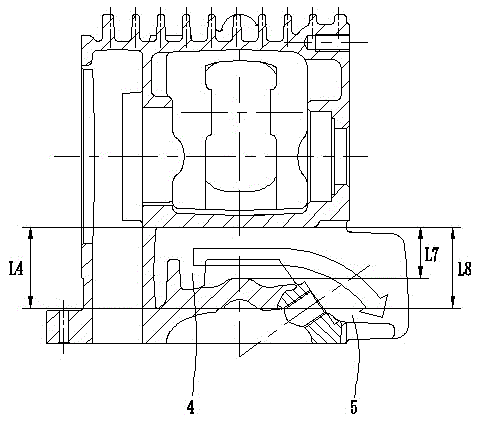

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the cylinder head of the three-valve engine has a cylinder head 1, and a cooling air passage is opened on the cylinder head 1, and the cooling air passage is successively composed of an air inlet 2, a first flow passage 3, a second flow passage 4 and an air outlet 5 Composition, the positions of the air inlet 2 and the air outlet 5 are the same as those of the prior art, and will not be repeated here. Wherein, the air inlet 2 is rectangular, the length L1 of the air inlet 2 is 32.5-39.5mm, and the width L2 is 30-36mm. In this embodiment, the length L1 of the air inlet 2 is preferably 36.5 mm, and the width L2 is preferably 33 mm. Inside the bottom of the air inlet 2 is provided a first guide channel 3 , and a first guide vane 6 for guiding the air flow to the first guide channel 3 is integrally fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com