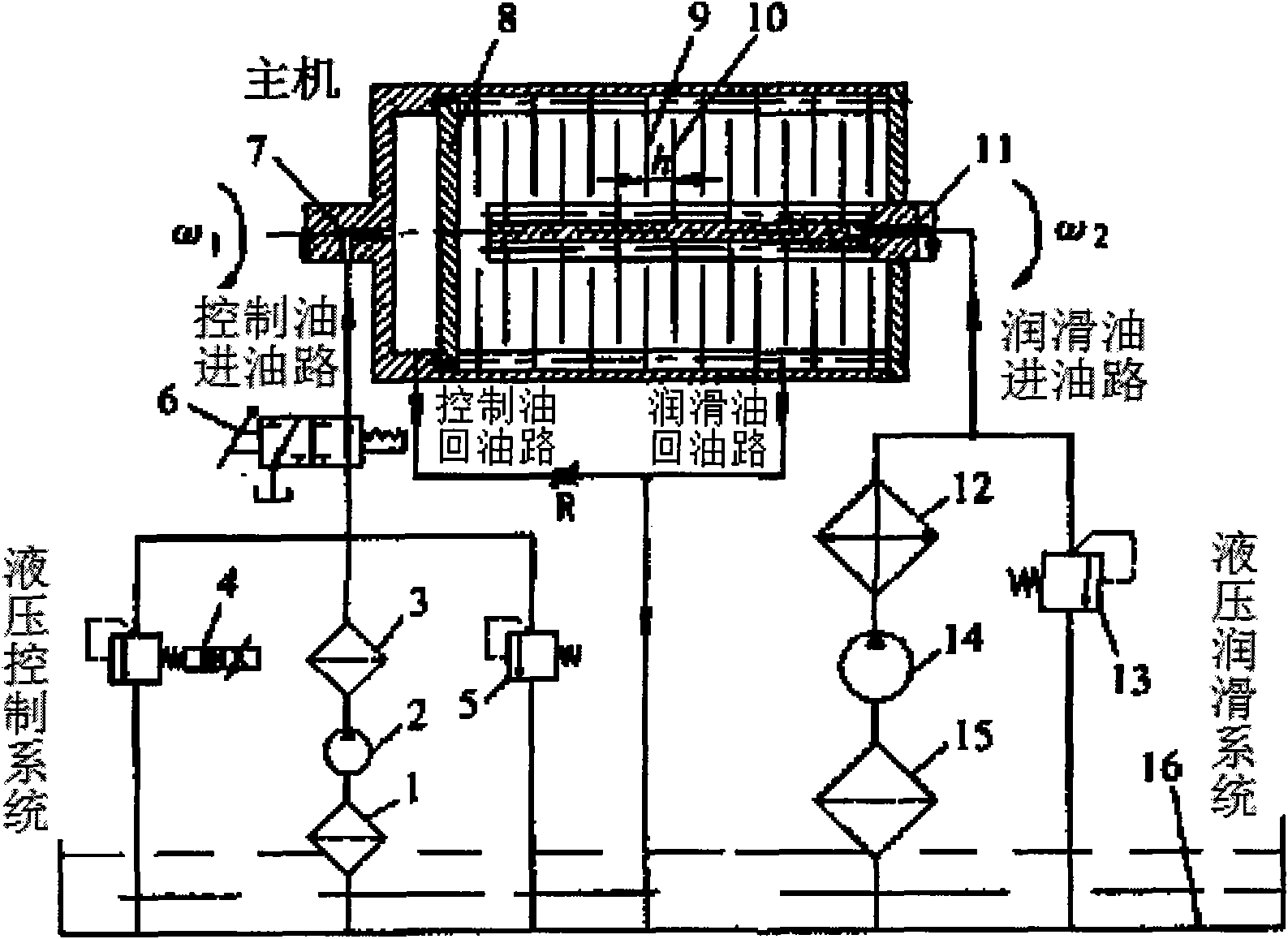

Design method for friction pair of hydro-viscous driver (HVD)

A technology of liquid viscosity and friction pair, which is applied in the field of clutches and can solve problems such as speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

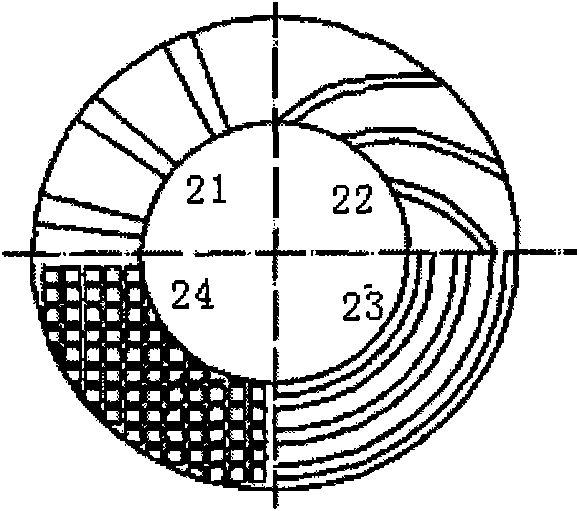

[0044] This embodiment provides a method for designing clutch friction pairs, which specifically includes the following steps:

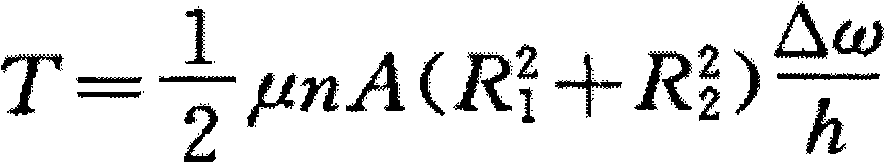

[0045] 1 Obtain the rated load of the friction pair

[0046] According to Newton's fluid shear theorem, the shear stress on the friction plate due to fluid viscosity at a radius r is

[0047] τ r = μ rΔω h - - - ( 1 )

[0048] In the formula, μ——oil dynamic viscosity; Δω——relative speed difference; h——oil film thickness

[0049] Both sides of formula (1) are multiplied by r, and both sides are from R 1 to R 2 Integral, the transfer torque of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com