Durability test stand for car door hinge and cover hinge

A technology for door hinges and lid hinges, which is applied in the field of durability test benches for automobile door hinges and lid hinges. Controllability, improved vehicle performance, and easy operation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

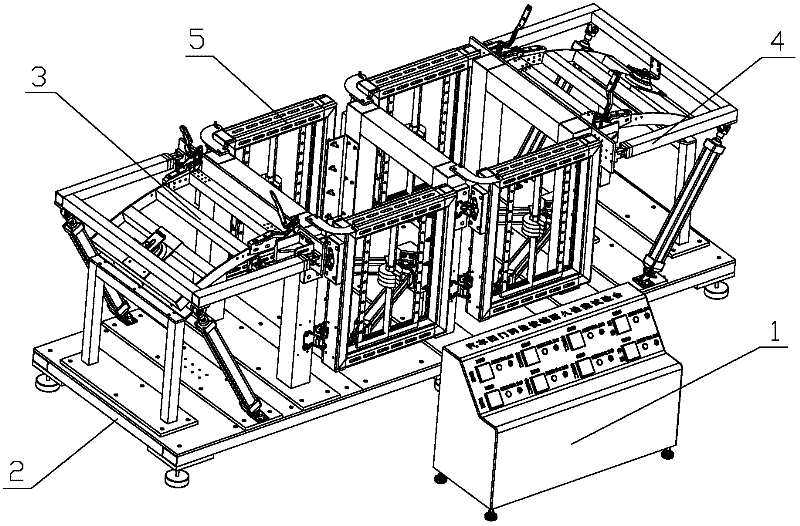

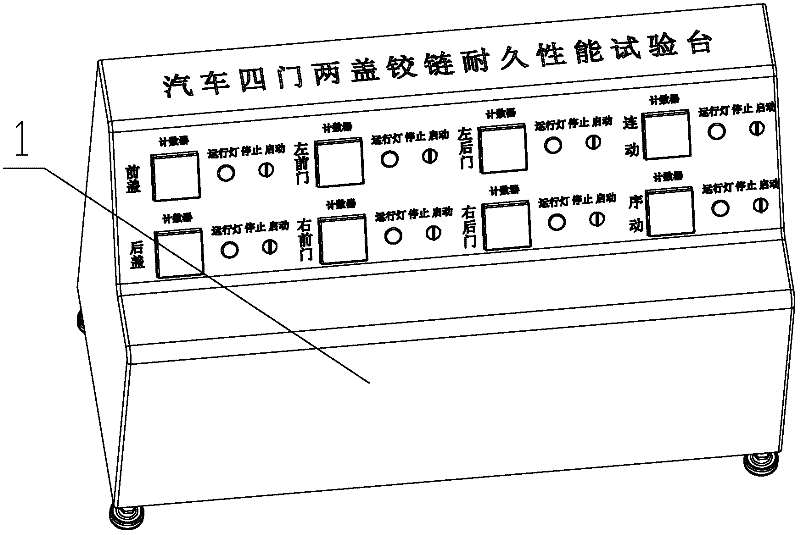

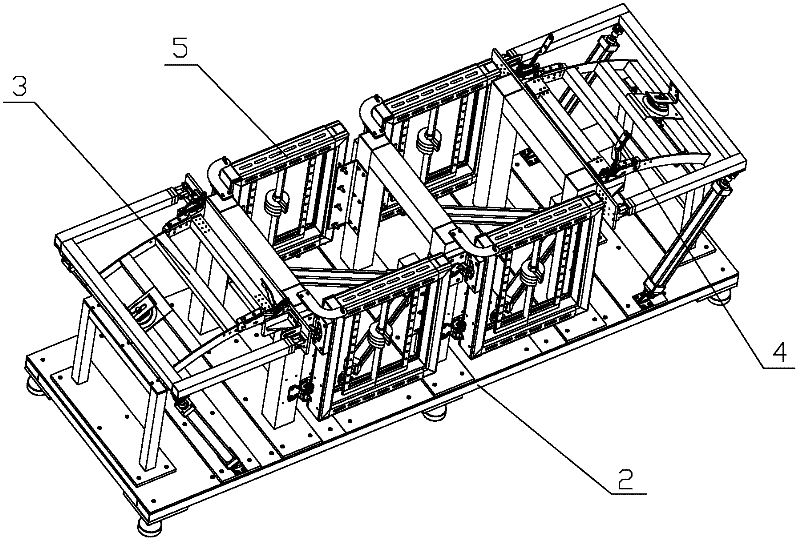

[0026] see Figure 1-Figure 3 Shown, a kind of automobile door hinge of the present invention and lid hinge durability performance test stand, for the endurance performance test of automobile door hinge and lid hinge, lid hinge comprises hair lid (front compartment lid) hinge 306 and rear lid (trunk lid) ) hinge 406, the test bench includes the control cabinet 1, the base steel frame assembly 2, and the cover hinge durable assembly 3 and the rear cover hinge that are arranged on the base steel frame assembly 2 and connected with the control cabinet 1 Durable assembly 4 and side door hinge durable assembly 5, side door hinge durable assembly 5 is located between hair cover hinge durable assembly 3 and rear cover hinge durable assembly 4. Sensors connected to the counters on the control cabinet 1 for sensing the number of movements of the door hinge or the cover hinge are respectively provided on the cover hinge durable assembly 3 , the rear cover hinge durable assembly 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com