Air tunnel fast braking test system

A brake test and brake system technology, applied in the field of test systems for testing vehicle performance, can solve problems such as low safety factor, cumbersome operation, and easy accidents, and achieve the effects of improved safety, simple and convenient operation, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

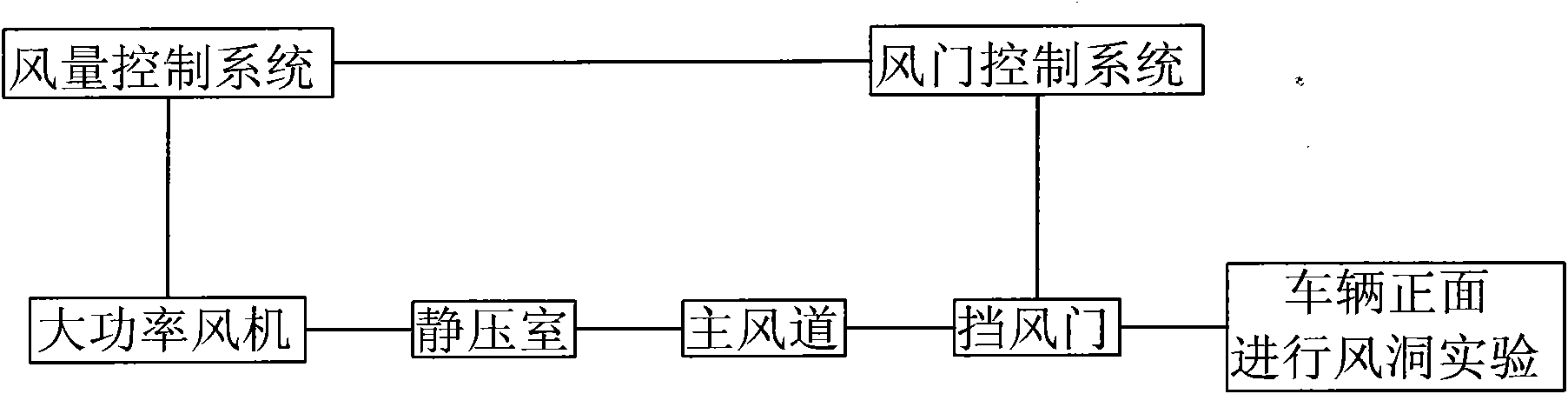

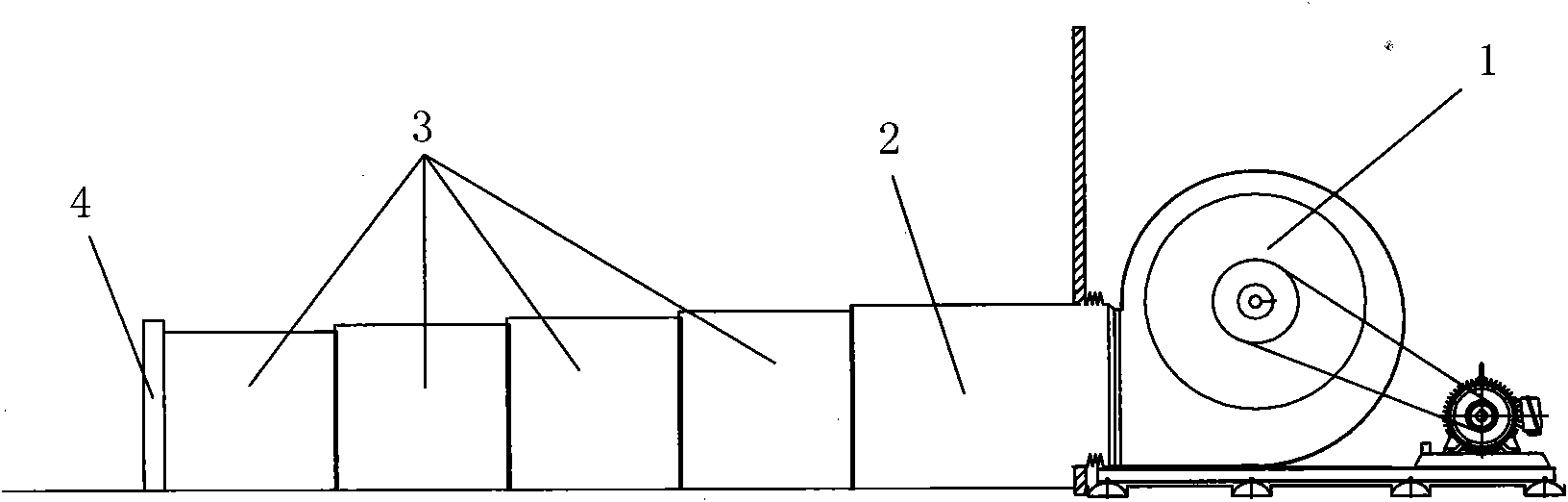

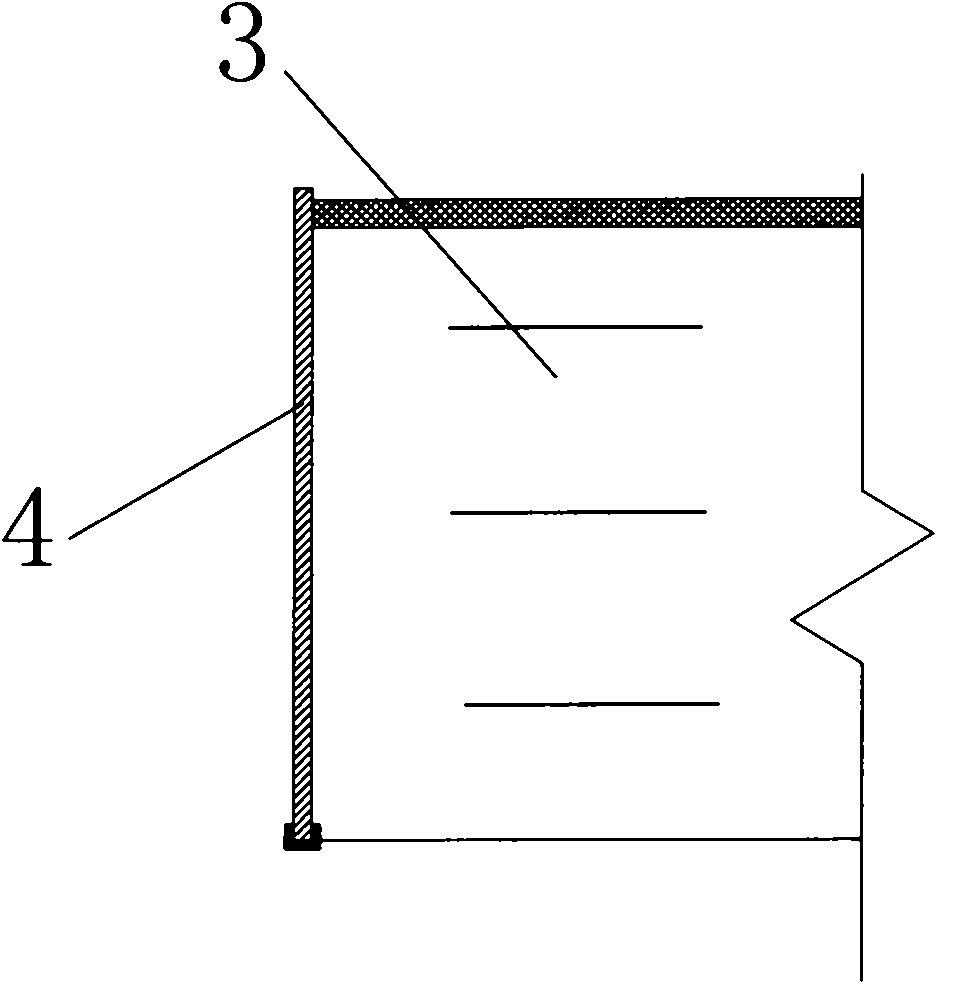

[0017] see Figure 4-6 , a fast braking test system in a wind tunnel, comprising a damper control system, an air volume control system, a blower fan 1, a static pressure chamber 2, a main air duct 3 and a movable damper 4, and the damper control system is respectively connected with the air volume control system and the static pressure Room 2 is connected, and the air volume control system is also connected with fan 1. Fan 1, plenum chamber 2 and main air duct 3 are sequentially arranged to form an air flow channel. The air flow output by fan 1 enters the active air duct 4 through plenum chamber 2, The wind tunnel quick braking test system also includes a secondary air duct 5 communicating with the static pressure chamber 2, and an air deflector 6 communicating with the secondary air duct 5 and the test space is arranged on the air outlet of the secondary air duct 5; 4 is set in the static pressure chamber 2, and a piston cylinder 7 that supports and adjusts the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com