Method for self-correcting coupling error of electromagnetic vector sensor array

A sensor array, electromagnetic vector technology, applied in the direction of measuring electrical variables, instruments, measuring devices, etc., can solve problems such as coupling error of electromagnetic vector sensor arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

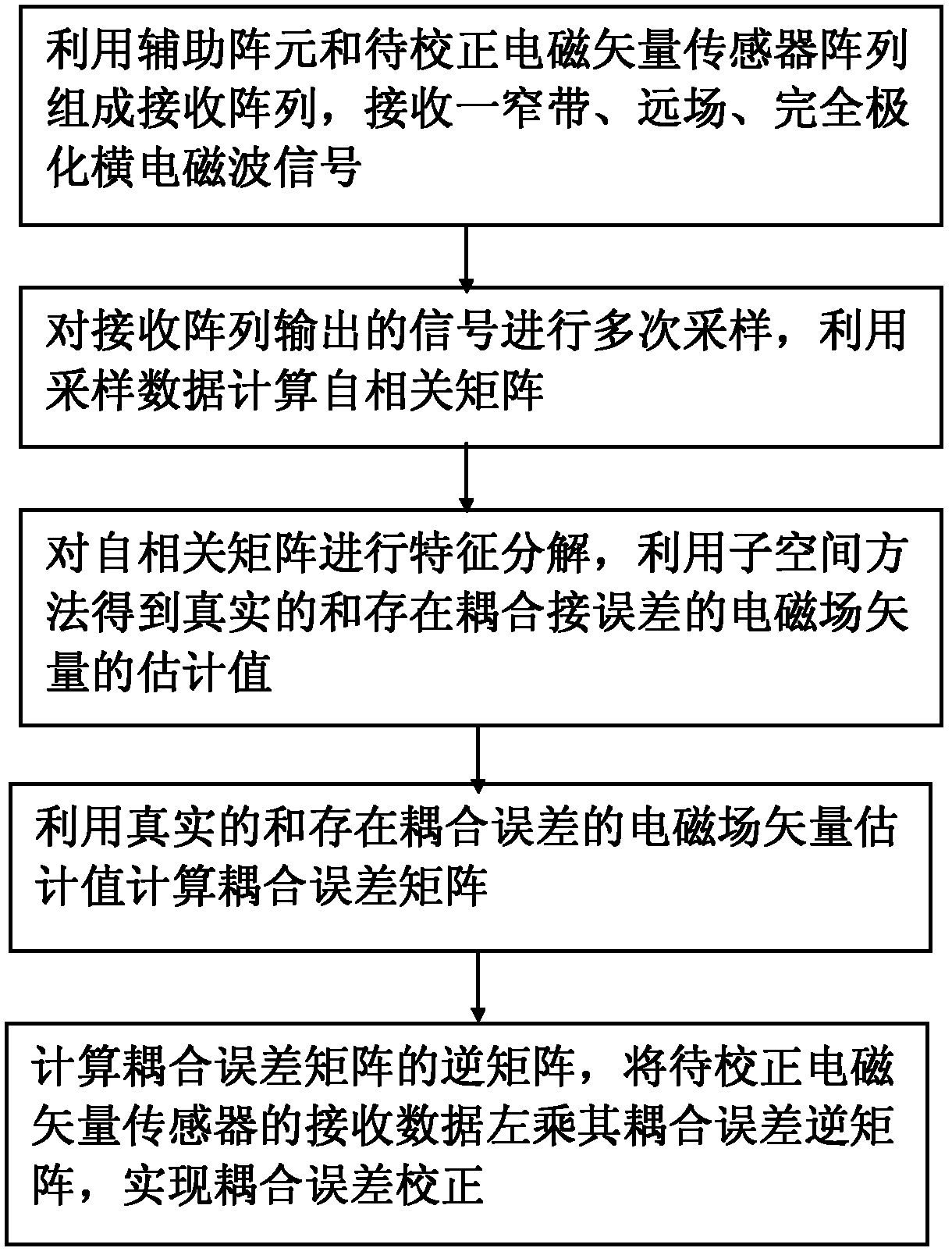

[0034] refer to figure 2 as shown, figure 2For the flow chart of the present invention, under the assumption that there is only coupling error in the electromagnetic vector sensor, that is, the magnitude and phase of the six channels of the electromagnetic vector sensor are all the same, by adding an auxiliary array element (ideal electromagnetic vector sensor) to the electromagnetic vector The coupling error of the sensor array is self-corrected, and the specific implementation steps of the self-correction method are as follows:

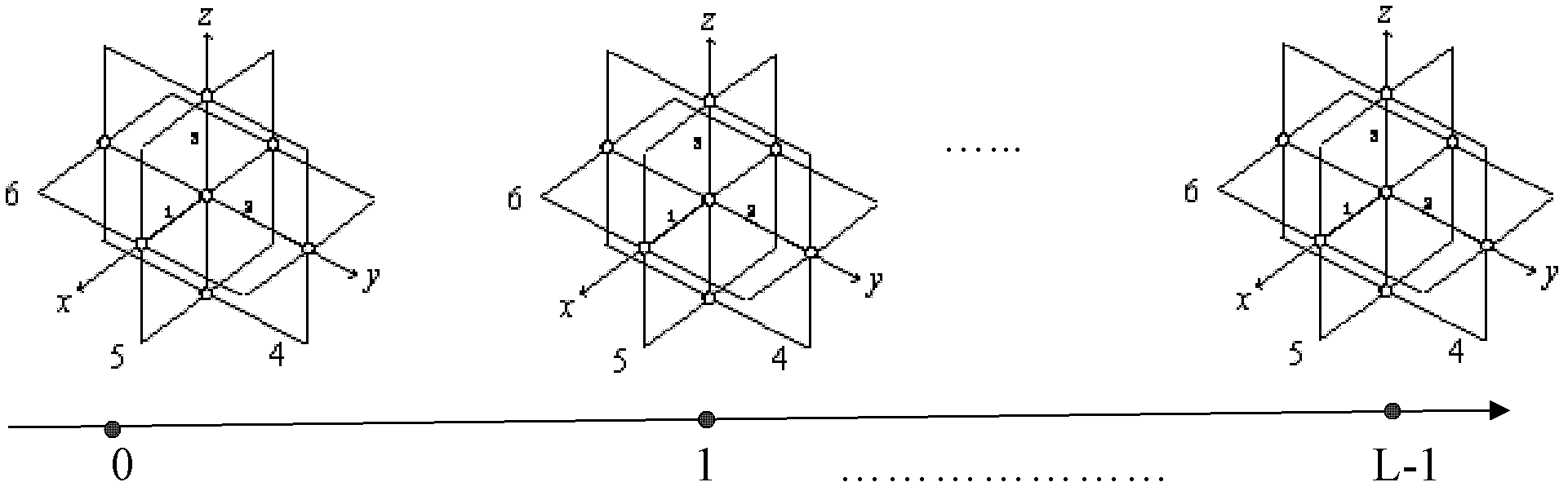

[0035] 1. An ideal electromagnetic vector sensor located at the origin of the coordinates is used as an auxiliary array element and L-1 electromagnetic vector sensors to be corrected to form a receiving array. The receiving array receives any narrowband, far-field, and fully polarized transverse electromagnetic wave signal. 1 time, the output signal of the receiving array for:

[0036] z ~ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com