Light guide for endoscope, endoscope equipped with light guide, and method for producing light guide for endoscope

An endoscope and light guide technology, which is applied to endoscopes and manufactures light guides for endoscopes, can solve problems such as harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

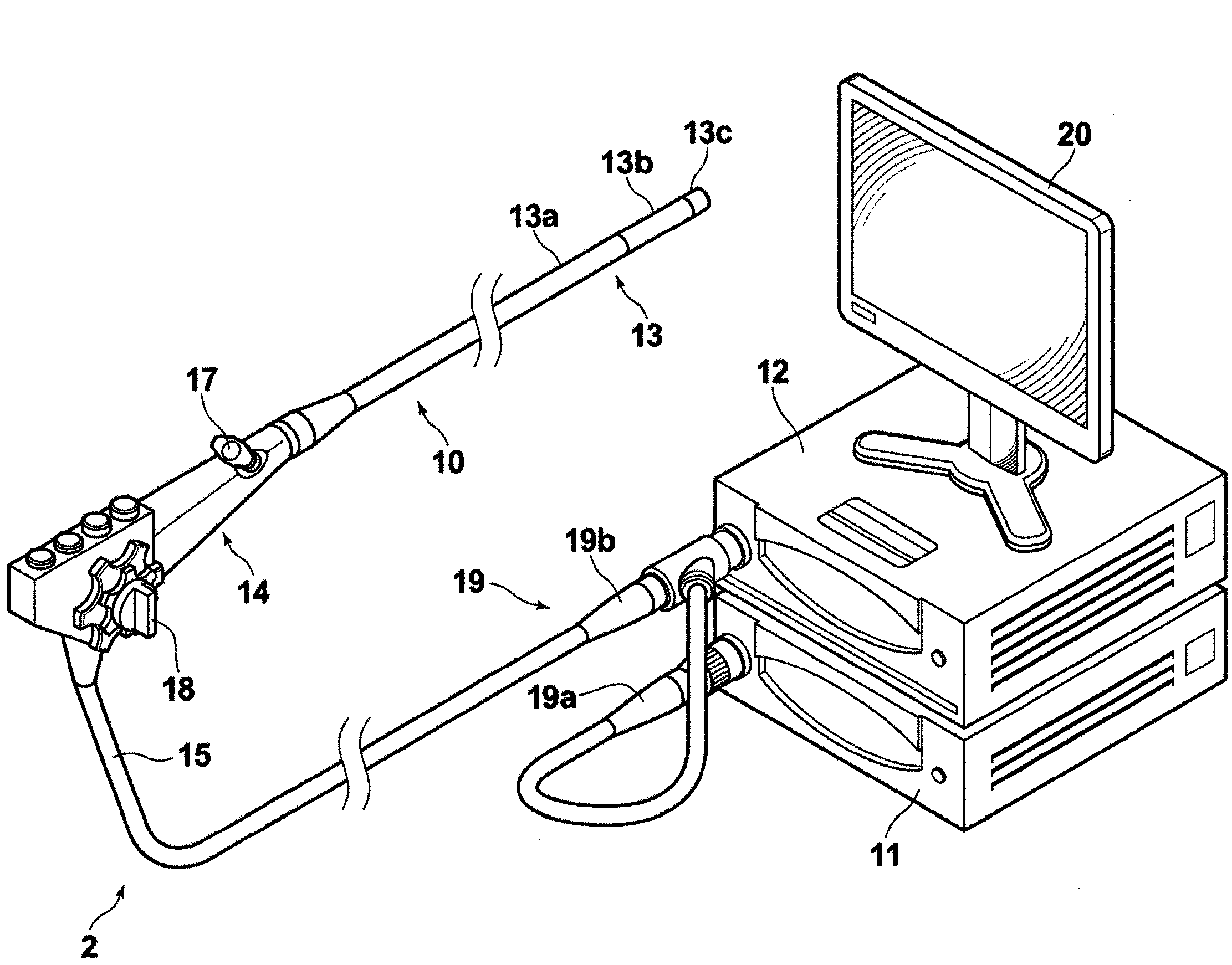

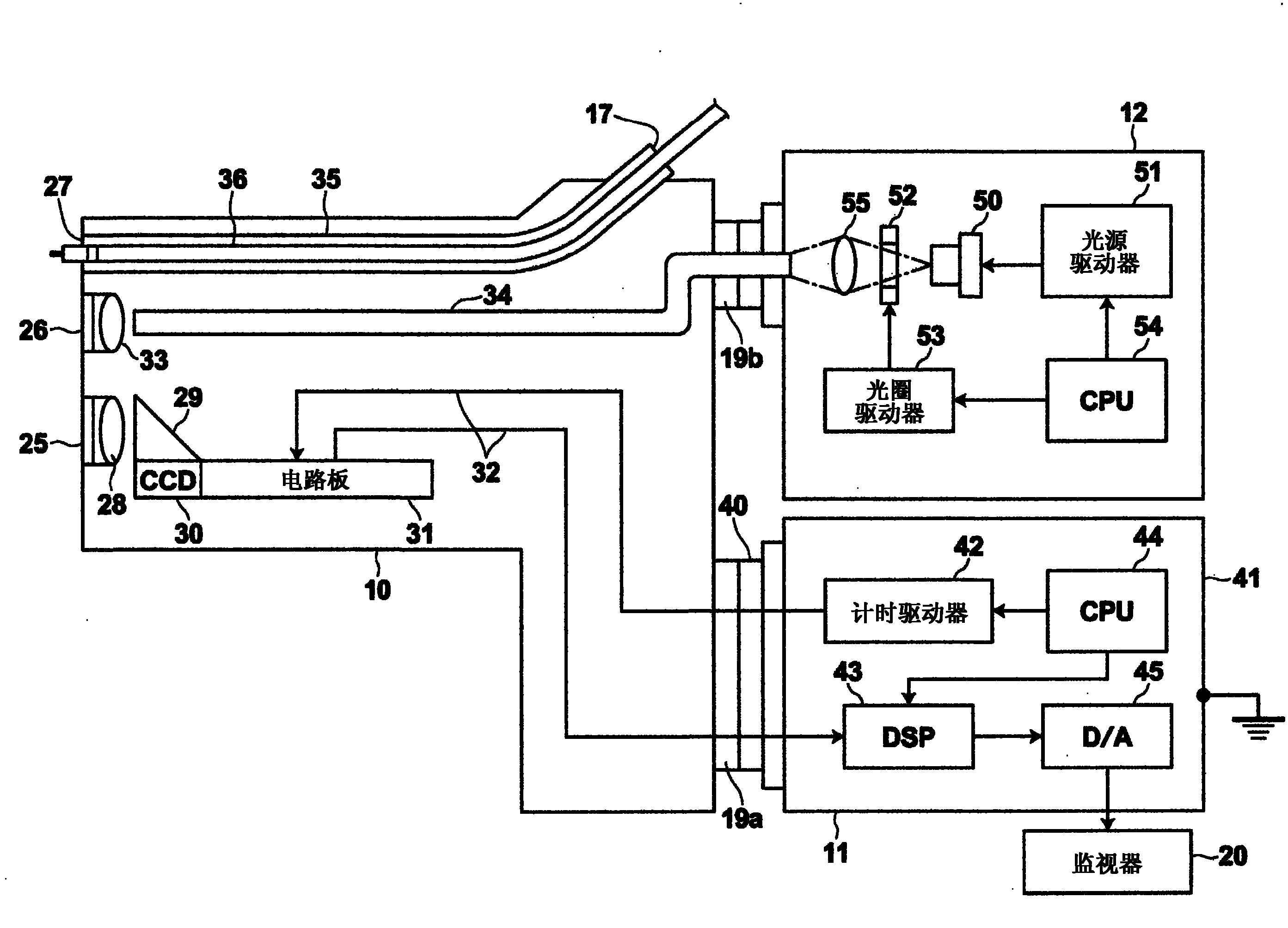

[0078] Embodiments of the light guide for endoscopes of the present invention will be described below.

Embodiment approach 1

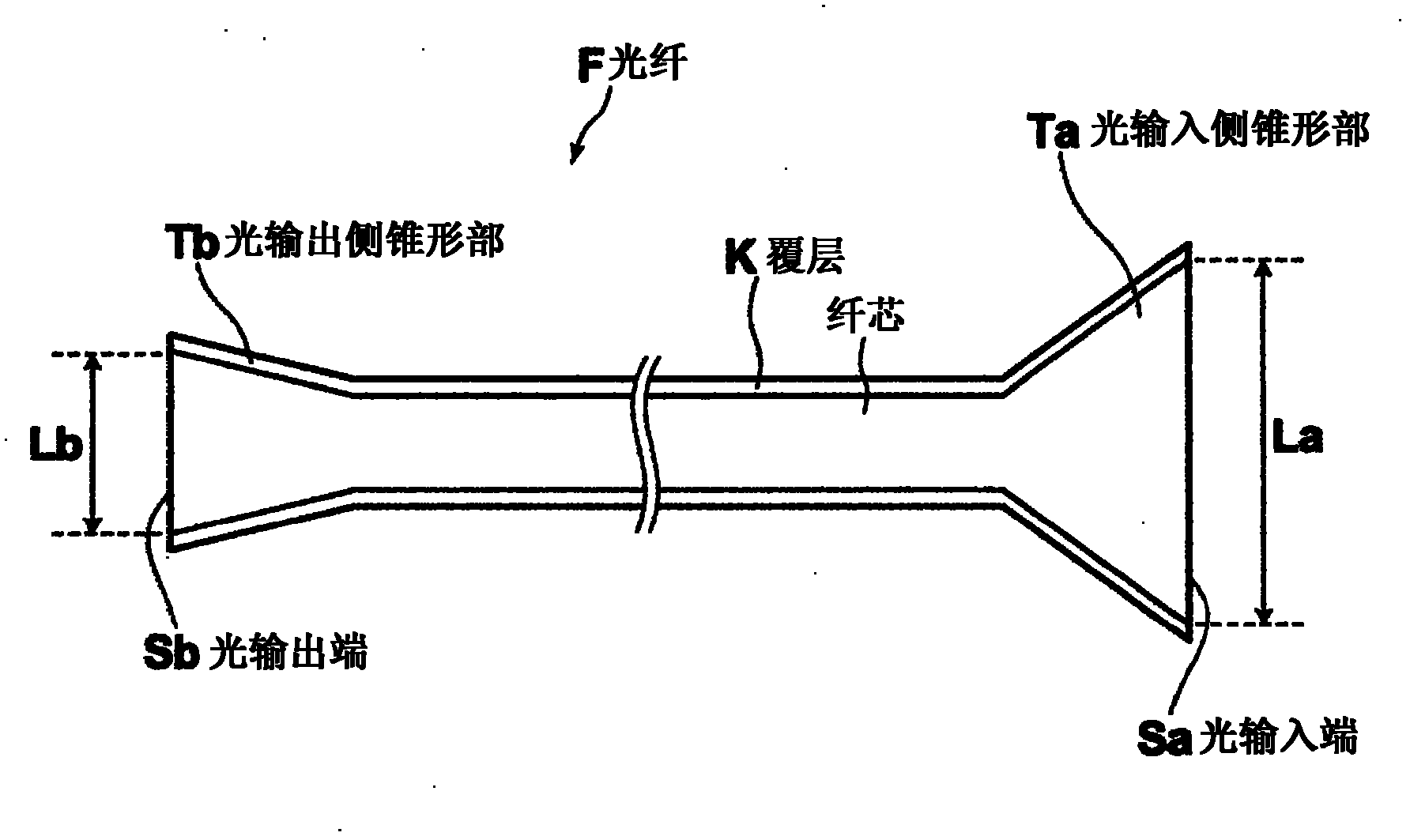

[0080] Two silica multimode optical fibers were prepared, the straight portion of the optical fiber had a numerical aperture NA of 0.22, a core diameter of 200 μm, a cladding diameter of 240 μm, and a total length of 2.5 m, and a tapered treatment was performed on the optical fibers so that the The first end of the optical fiber has a tapered shape that becomes thicker towards the end. One of the two optical fibers is tapered so that tapering starts at a position 50 cm away from the first end, and the core diameter at the first end is 700 μm. The other of the two optical fibers is tapered so that the tapering starts at a position 50 cm away from the first end, and the core diameter at the first end is 300 μm. Subsequently, the thin-diameter ends (ends not subjected to tapering processing) of the first optical fiber and the second optical fiber were melted. Therefore, an optical fiber bundle having a light-input-side tapered portion thickened toward an end having a core diamet...

Embodiment approach 2

[0083] Two silica multimode optical fibers are prepared, the linear portion of the optical fiber has a numerical aperture NA of 0.5, a core diameter of 100 μm, a cladding diameter of 115 μm, and a total length of 2.5 m, and the optical fiber is tapered so that The first end of the optical fiber has a tapered shape that becomes thicker toward the end. One of the two optical fibers is tapered so that tapering starts at a position 50 cm away from the first end, and the fiber core diameter at the first end is 700 μm. The other of the two optical fibers is tapered so that tapering starts at a position 50 cm away from the first end, and the core diameter at the first end is 300 μm. Subsequently, the thin-diameter ends (ends not subjected to tapering treatment) of the first optical fiber and the second optical fiber were melted. Therefore, an optical fiber bundle having a light-input-side tapered portion thickened toward an end having a core diameter of 700 μm at the end and a light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com