High-brightness LED illumination dodging system

A LED lighting, high-brightness technology, applied in the direction of lighting devices, lighting and heating equipment, parts of lighting devices, etc., can solve the problems of large volume, increased cost, and difficulty in meeting the requirements of miniaturization of instruments, etc., to achieve volume reduction , reduce light loss and improve energy collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

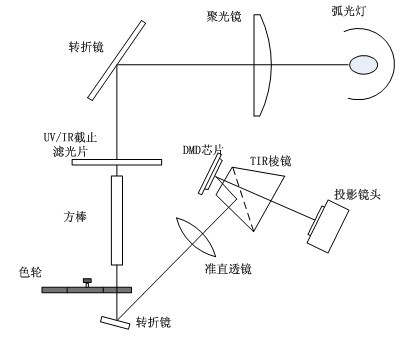

[0040] Such as Figure 4 As shown, a high-brightness LED lighting uniform light system is shown, which includes a high-brightness LED module 1, and an LED light-emitting chip 2 is arranged on the high-brightness LED module 1, and the positive side of the LED light-emitting chip 2 is The front is provided with a homogenizing rod, and a color wheel 7 is arranged directly in front of the homogenizing rod. The homogenizing rod includes a tapered structure part 3, and the size of the incident end of the tapered structure part 3 is smaller than that of the outgoing end. Size, the incident end face of the tapered structure part 3 is rectangular or other shapes, its size is preferably close to the size of the light source, the outgoing end face is a rectangular structure, and the aspect ratio of the rectangular structure is 4:3 or 16:9 , the floating range is within 10%.

[0041] The homogenizing rod further includes a rectangular structure part 4, which is located at the incident en...

Embodiment 2

[0047] Such as Figure 5 As shown, a high-brightness LED lighting uniform light system is shown, and the main difference from Embodiment 1 is that the rectangular structure part 4 of the light uniform rod is in the direction close to the LED light-emitting chip 2. This structure is essentially the same as that of Embodiment 1. The above are the same, and the energy coupling efficiency is equivalent. The main reason is that the position of the positioning plate 5 of the uniform light rod is close to the high-brightness LED module 1, which changes the clamping method of the fixture.

Embodiment 3

[0049] Such as Figure 6 As shown, a high-brightness LED lighting homogenization system is shown, and the main difference from Embodiment 1 is that the structure of the homogenization rod has changed, which only consists of a tapered structure part 3 and does not include a rectangular structure part 4 . The incident end face of the tapered structure part 3 is rectangular or other shapes, and its size is preferably close to the size of the light source, and the outgoing end face is a rectangular structure, and the aspect ratio of the rectangular structure is 4:3 or 16:9 (or approximately Proportion). This structure is essentially the same as Embodiment 1, and the energy coupling efficiency is equivalent, mainly because the rectangular structure part 4 of the dodging rod is omitted, and the clamping mode of the clamp is changed at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com