Fixing structure for mobile phone touch screen

A fixed structure, touch screen technology, applied in the direction of telephone structure and other directions, can solve the problems of high manufacturing cost of metal frame, inability to take into account the shockproof function, cracking of the touch screen, etc., and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

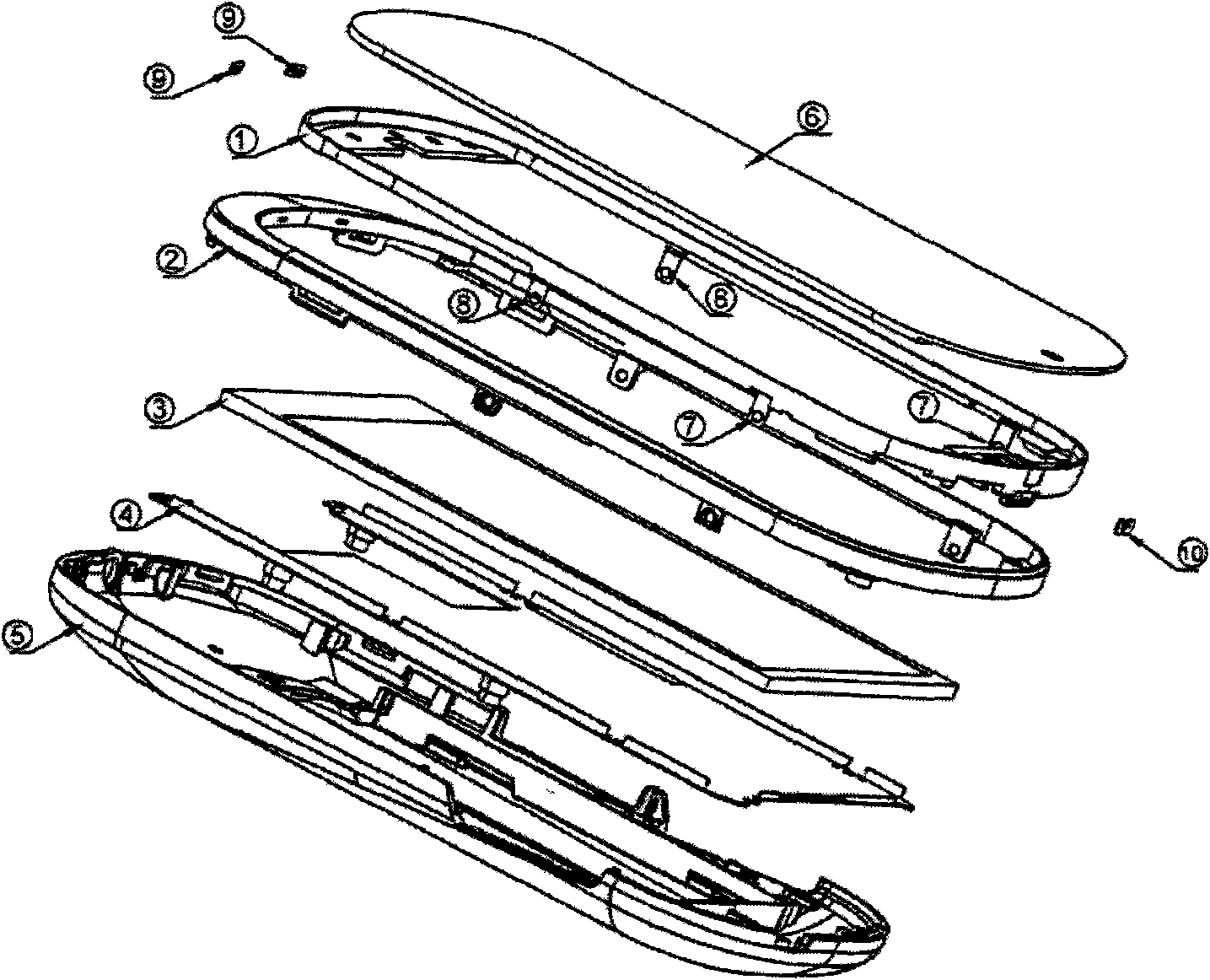

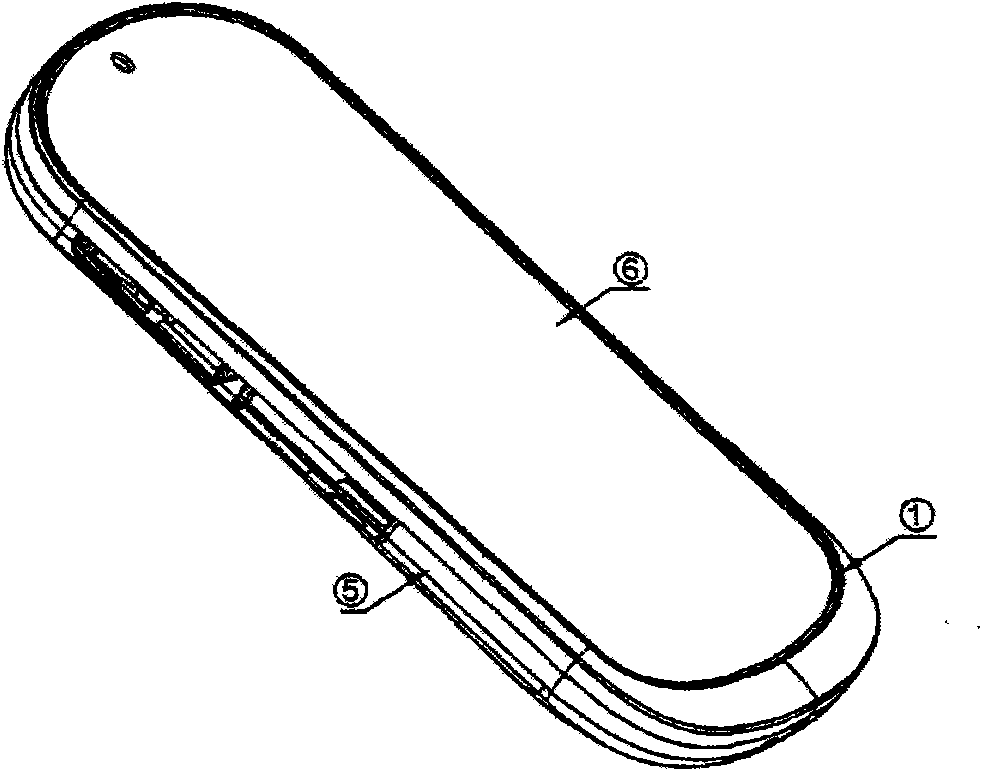

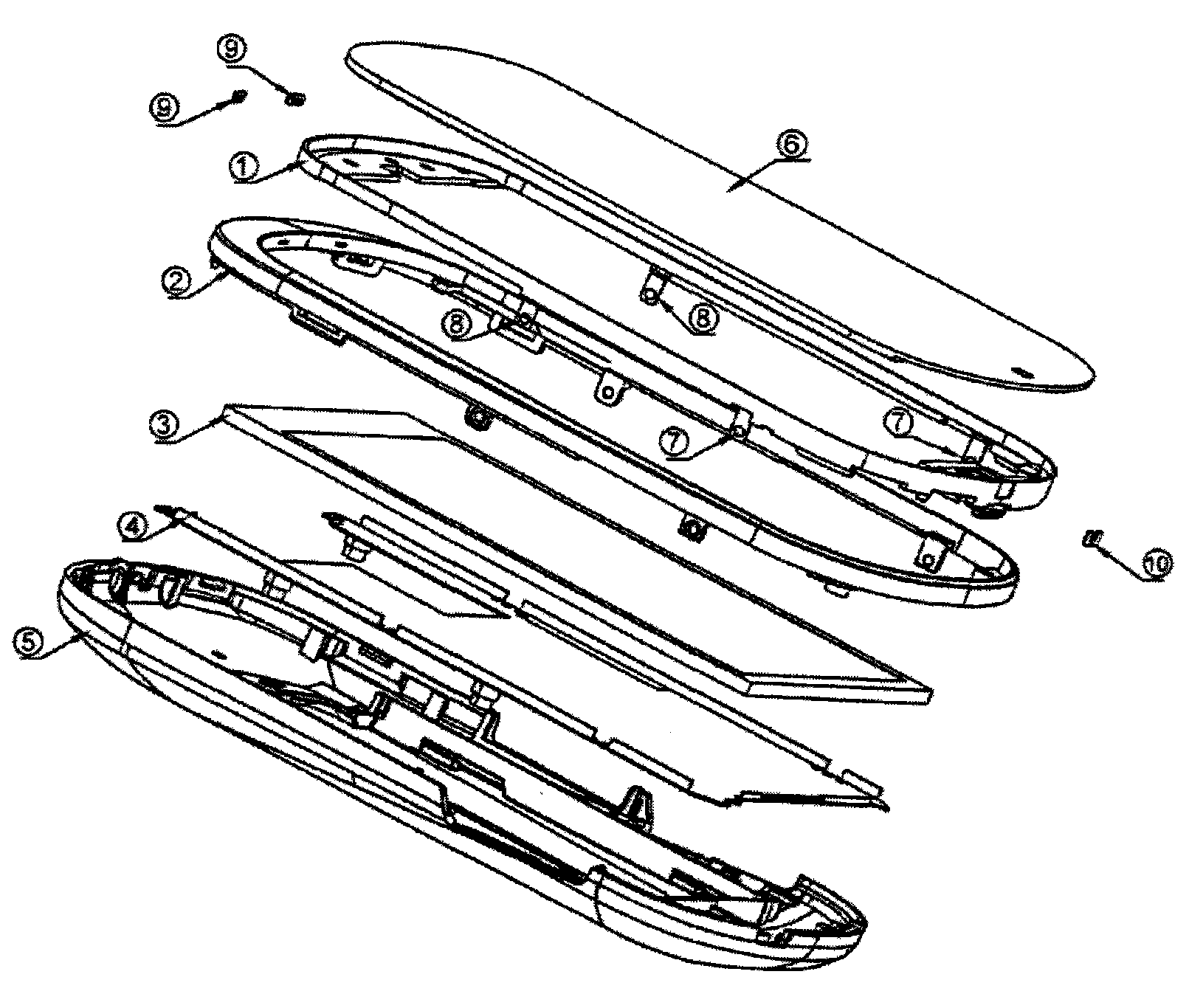

[0011] figure 1 In the embodiment shown, the mobile phone touch screen fixing structure includes a plastic body 1, a metal frame 2, a display 3, a mobile phone back cover 5, and a touch screen 6. The plastic body 1 molded at one time and the touch screen 6 are closely matched by dimensional tolerances. The adhesive is bonded together, so that the entire touch screen is in contact with the plastic body to achieve a shock absorption effect. After the plastic body 1 is bonded to the touch screen, it is fixed with the metal frame 2 through a tight fit with dimensional tolerances. The lower part of the display 3 is padded with a shielding cover. 4. Installed in the metal frame 2, the plastic body 1 cooperates with the back cover 5 of the mobile phone through the structural clamping position, the plastic body 1 includes metal sheets 7, 8, 9, 10, and the metal frames 7, 8, 9, 10 connect with the metal frame 2 Interlock with screws to make the phone solid as a whole. The touch screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com