Double-sided self-lock zipper slider

A zipper slider and self-locking technology, which is applied in the field of zipper sliders, can solve the problems of complex overall structure and difficult assembly of zipper sliders, and achieve the effect of simple structure, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

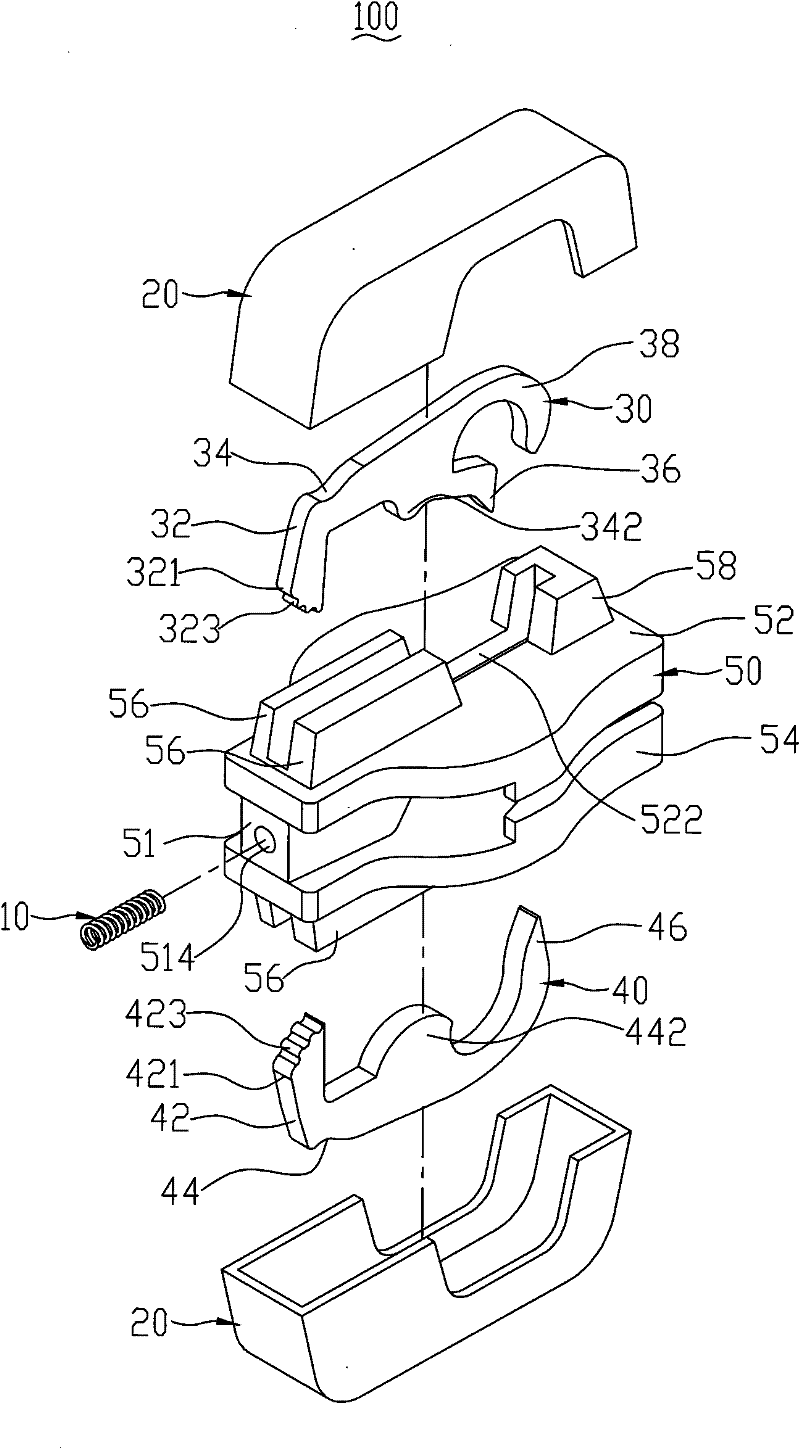

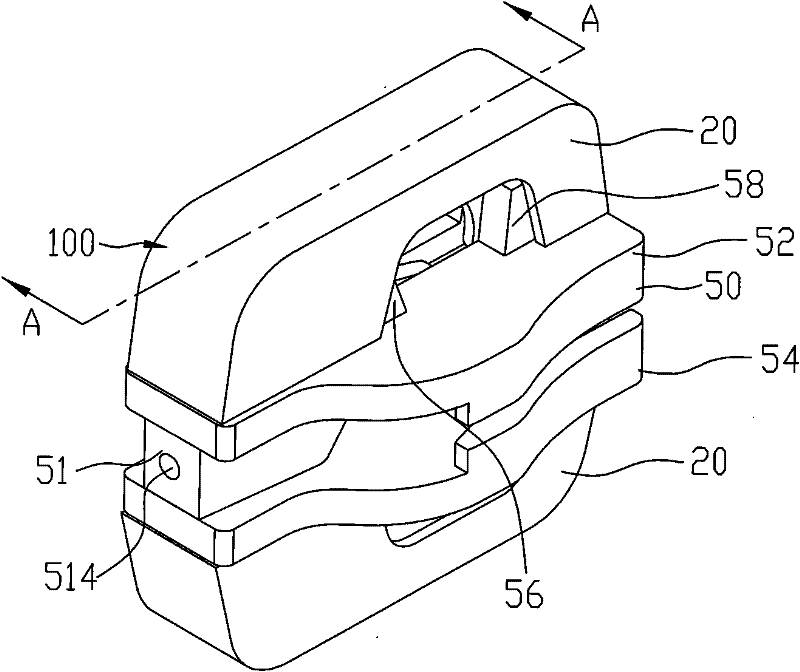

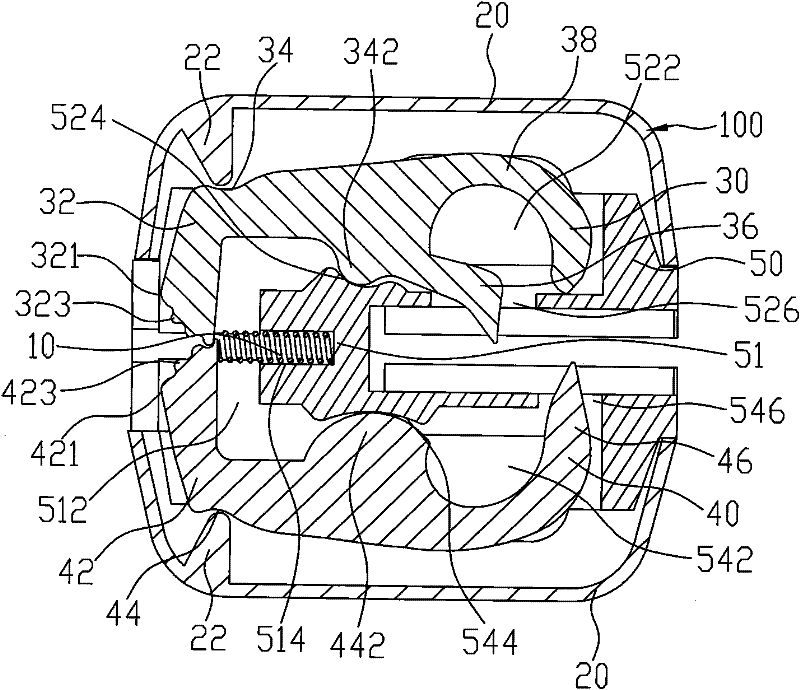

[0036] figure 1 It is a three-dimensional exploded view of the first embodiment of the double-sided self-locking zipper slider of the present invention. The double-sided self-locking zipper puller 100 includes a spring 10 , a pair of caps 20 , an upper hook 30 , a lower hook 40 , a slider body 50 and a pair of pull tabs (not shown). The spring 10, the upper hook 30 and the lower hook 40 are housed in the slider body 50, the spring 10 is located between the upper hook 30 and the lower hook 40, and the two caps 20 are respectively assembled on the slider body The upper and lower sides of 50 (such as image 3 shown).

[0037] Please refer to figure 1 , the cap 20 is surrounded by a top wall and four side walls to form a rectangular semi-closed shell structure with one side opening, and the lower surface of the front end of the top wall of the cap 20 is integrally formed downwards with a pressing block 22 (such as image 3 shown).

[0038] Please refer to figure 1 and imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com