Agricultural nano-hybrid organic silicon defoaming agent and preparation method thereof

An organosilicon defoamer and hybrid technology, applied in the field of modified silica particles and their preparation, can solve the problems of poor defoaming ability of silicone oil and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

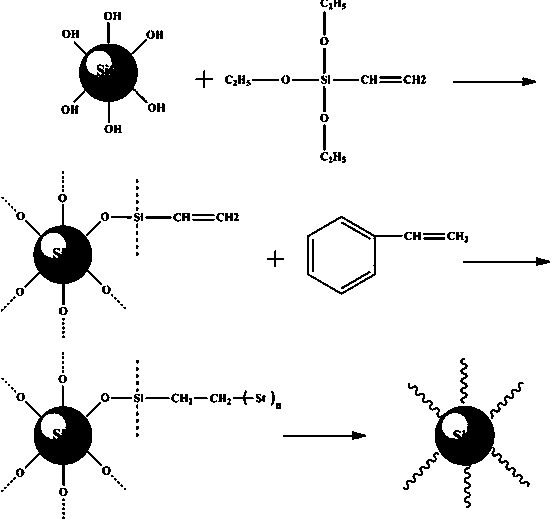

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of nano-hybrid organic silicon defoamer, comprises the following steps:

[0028] (1) Using a planetary ball mill as a modification tool, add 1.5g of 21-25nm silica particles into the ball milling tank, then add 1.5g of vinyltriethoxysilane and 22g of toluene into the ball milling tank, the ball milling beads and the material quality The ratio is 5:1, add ball milling beads, the ball milling beads are ball milling beads with particle sizes of 5mm, 2.5mm and 1.5mm respectively, and the mass ratio of ball milling beads with different particle sizes is 1:2:3; the ball milling tank is sealed and fixed In the ball mill, control the speed of the ball mill to 500-530 r / min, and the ball milling time is 4h;

[0029] (2) Pour the product of step (1) into a four-necked bottle and continue to react for 4 hours;

[0030] (3) Take 1 g of the product of step (2) and disperse it in 22 g of xylene, and ball mill it again for 4 hours with a ball mill;

[0031] (4...

Embodiment 2

[0033]Take 1g of silica particles modified by silane coupling agent and disperse in 50g of mixed silicone oil (this silicone oil is compounded from silicone oil with viscosities of 500, 1000, and 5000 respectively in a mass ratio of 5:3:2), and the prepared Get a dispersion. Take 9g of this dispersion, and add 1.35g of emulsifier (the emulsifier is compounded by TX-10 and TX-4 at a mass ratio of 3.5:2.5), and then add 20g of water for emulsification to obtain an agricultural nano-hybrid organic Silicon defoamer.

[0034] Take 100ml of the foaming liquid in a graduated 250ml measuring cylinder, and shake it 360 times in a vertical shaker / The frequency of min was oscillated for 2 minutes, and then 0.1ml of agricultural nano-hybrid silicone defoamer was added. The instantaneous defoaming rate was measured to be 33.33ml / s, and the number of cycles measured by the foam suppression test was 90 times.

Embodiment 3

[0036] Take 1g of silica particles modified by silane coupling agent and disperse them in 50g of mixed silicone oil (this silicone oil is compounded from silicone oil with a viscosity of 500, 1000, 5000 in a mass ratio of 4:3:4) to obtain Dispersions. Take 9g of this dispersion, and add 1.35g of emulsifier (the emulsifier is compounded by TX-10 and TX-4 at a mass ratio of 3.5:2.5), and then add 20g of water for emulsification to obtain an agricultural nano-hybrid organic Silicon defoamer.

[0037] Take 100ml of the foaming liquid in a graduated 250ml measuring cylinder, and shake it 360 times in a vertical shaker / The frequency of min was oscillated for 2 minutes, and then 0.1ml of agricultural nano-hybrid silicone defoamer was added, and the instantaneous defoaming rate was 31.25ml / s. The number of cycles measured by the anti-foaming test was 110 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com