A kind of fully synthetic cutting fluid and preparation method thereof

A cutting fluid and fully synthetic technology, applied in the field of metal cutting, can solve the problems of increasing cost and affecting the quality of workpieces, etc., and achieve the effects of enhancing adsorption, saving cost and manpower, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

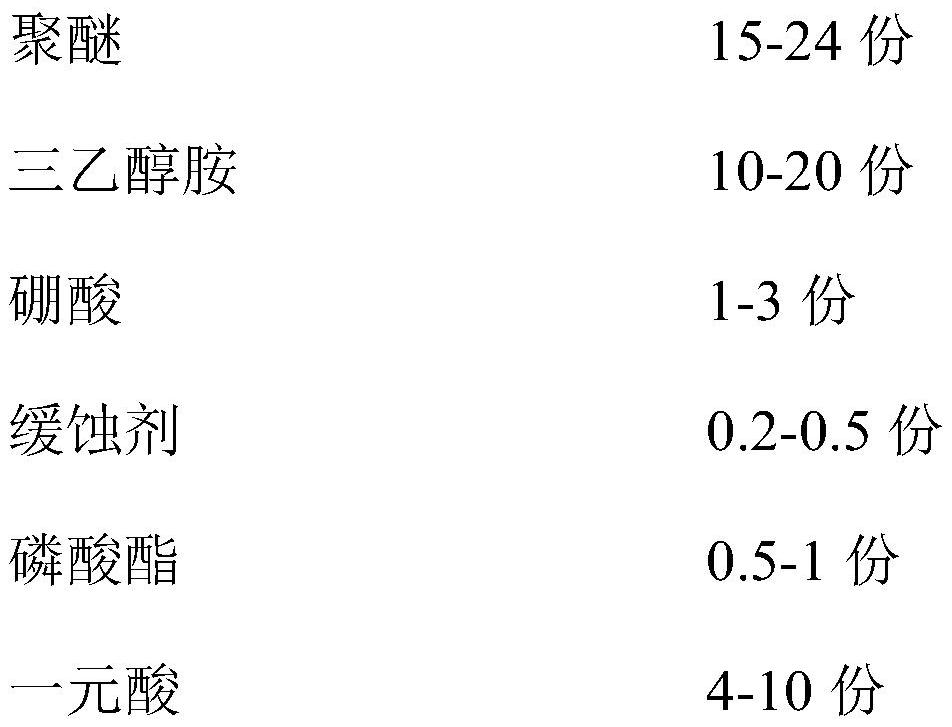

Method used

Image

Examples

Embodiment 1

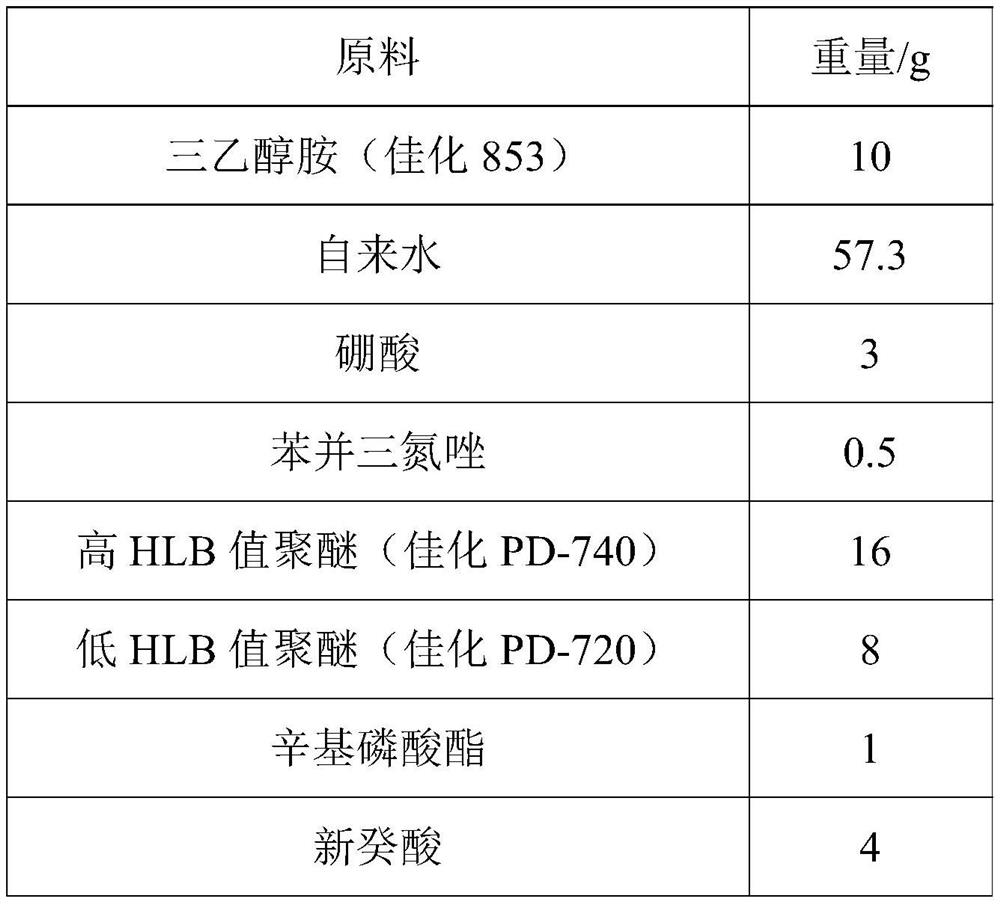

[0035] The present embodiment provides a fully synthetic cutting fluid, the composition of which is shown in the following table:

[0036] Table 2 Example 1 Composition

[0037]

[0038]

[0039] The components in Table 2 were added to the container one by one and stirred at room temperature, the stirring rate was 100 r / min, and the stirring time was 60 min to obtain a fully synthetic cutting fluid.

Embodiment 2

[0041] The present embodiment provides a fully synthetic cutting fluid, the composition of which is shown in the following table:

[0042] Table 3 embodiment 2 composition

[0043] raw material Weight / g Triethanolamine (Optimized 853) 15 tap water 56.5 Boric acid 2 benzotriazole 0.3 High HLB value polyether (optimized PD-740) 12 Low HLB value polyether (optimized PD-720) 6 Octyl Phosphate 0.7 neodecanoic acid 7 Alkynyl ether (Optimized KM-420) 0.5

[0044] The components in Table 3 were added to the container one by one and stirred at room temperature, the stirring rate was 200 r / min, and the stirring time was 45 min to obtain a fully synthetic cutting fluid.

Embodiment 3

[0046] The present embodiment provides a fully synthetic cutting fluid, the composition of which is shown in the following table:

[0047] Table 4 embodiment 3 composition

[0048] raw material Weight / g Triethanolamine (Optimized 853) 20 tap water 52.3 Boric acid 1 benzotriazole 0.2 High HLB value polyether (optimized PD-740) 10 Low HLB value polyether (optimized PD-720) 5 Octyl Phosphate 0.5 neodecanoic acid 10 Alkynyl ether (Optimized KM-420) 1

[0049] All components in Table 3 were added to the container and stirred at room temperature, the stirring rate was 300 r / min, and the stirring time was 30 min to obtain a fully synthetic cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com