Emulsifying type cutting fluid and preparation method

A cutting fluid and emulsified technology, applied in the petroleum industry, lubricating composition, etc., can solve the problem of machining workpiece residue, etc., and achieve the effect of low production cost, good effect and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

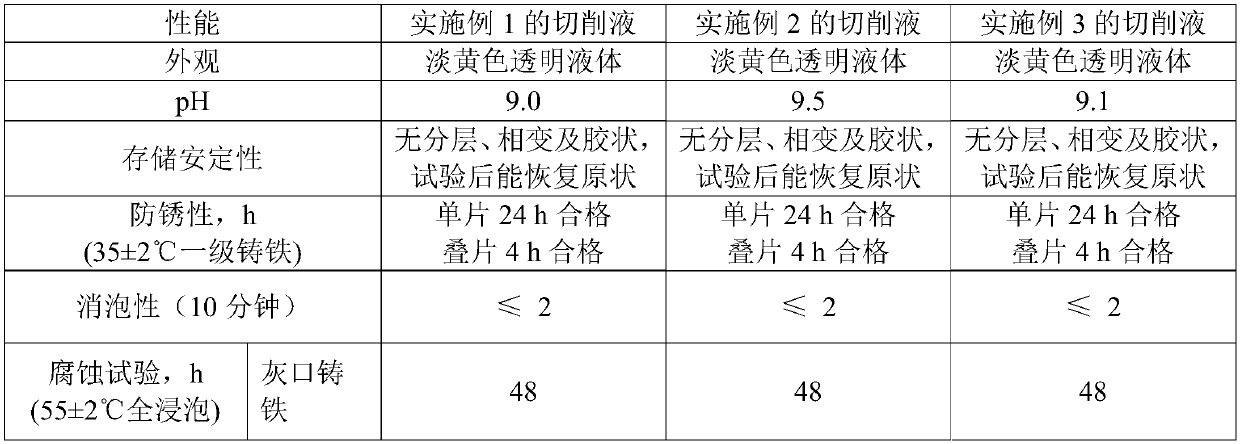

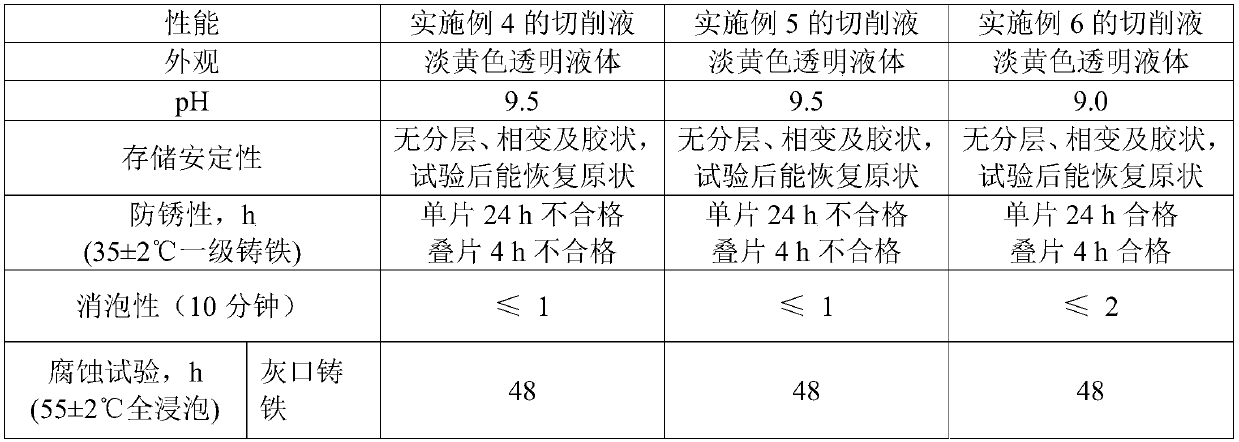

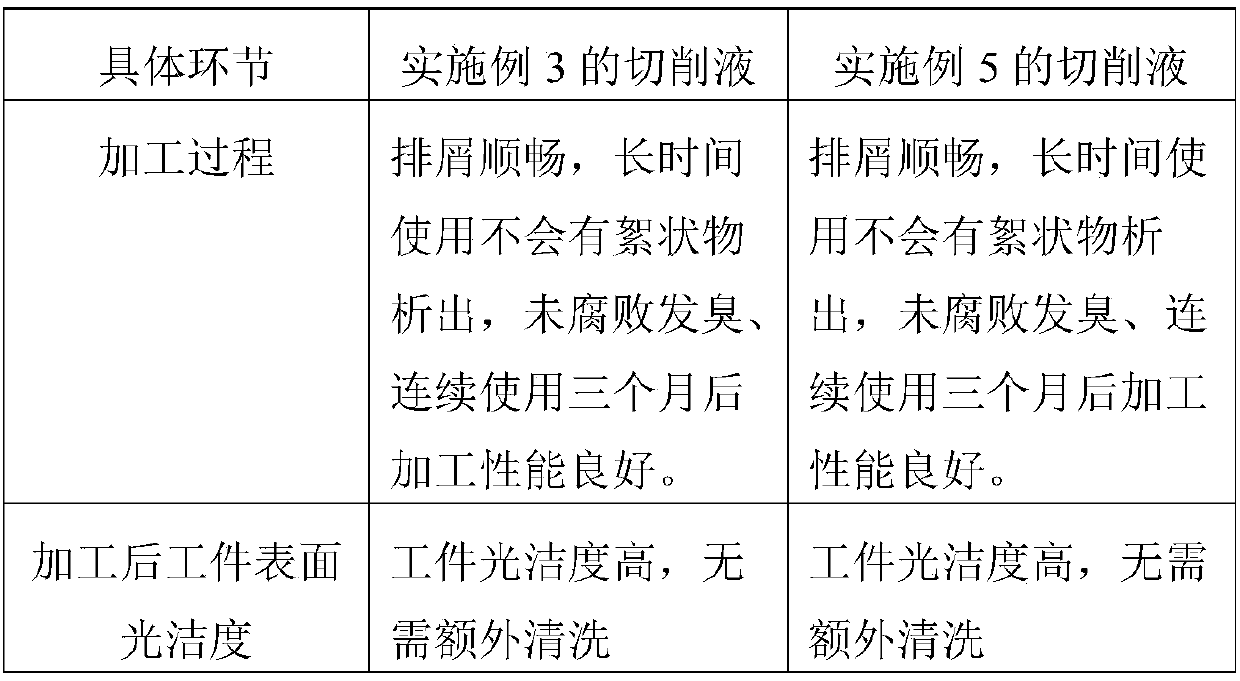

Examples

Embodiment 1

[0028] Emulsified cutting fluid, the raw material contains the following components in parts by weight:

[0029] 35 parts of base oil, 7 parts of self-emulsifying ester, 6 parts of low-foaming emulsifier, 7 parts of pH regulator, and 10 parts of water.

[0030] Wherein, the base oil is a naphthenic base oil.

[0031] The self-emulsifying ester is Priolibe3952.

[0032] The low foam emulsifier is Synperonic PE / L25R2.

[0033] The pH regulator is monoethanolamine.

Embodiment 2

[0035] Emulsified cutting fluid, the raw material contains the following components in parts by weight:

[0036] 55 parts of base oil, 15 parts of self-emulsifying ester, 12 parts of low-foaming emulsifier, 15 parts of pH regulator, and 25 parts of water.

[0037] Wherein, the base oil is an intermediate base oil.

[0038] The self-emulsifying ester is Priolibe3953.

[0039] The low foam emulsifier is Synperonic PE / L62.

[0040] The pH regulator is diethanolamine.

Embodiment 3

[0042] Emulsified cutting fluid, the raw material contains the following components in parts by weight:

[0043] 45 parts of base oil, 10 parts of self-emulsifying ester, 9 parts of low-foaming emulsifier, 10 parts of pH regulator, and 17 parts of water.

[0044] Wherein, the base oil is one or a mixture of naphthenic base oil, intermediate base oil, paraffin base oil, 10# white oil and 15# white oil.

[0045] The self-emulsifying ester is one or a mixture of Priolibe3952, Priolibe3953, Priolibe3955 and Priolibe3961.

[0046] The low-foaming emulsifier is one or a mixture of Synperonic PE / L25R2, Synperonic PE / L62, Synperonic PE / L64 and Synperonic PE / L101.

[0047] The pH regulator is one or a mixture of monoethanolamine, diethanolamine, triethanolamine, isopropanolamine, diisopropanolamine, triisopropanolamine and fatty alcohol amides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com