Method for processing right-angle roller path of slewing bearing of crossed roller

A technology of slewing bearings and crossed rollers, which is applied in the field of bearing processing, can solve the problems that the angle of 45 degrees cannot be accurately guaranteed and measured, the size and shape tolerance of the two raceways cannot be guaranteed, and the processing accuracy cannot be guaranteed. The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A processing method for a right-angle raceway of a cross roller slewing bearing includes the following steps:

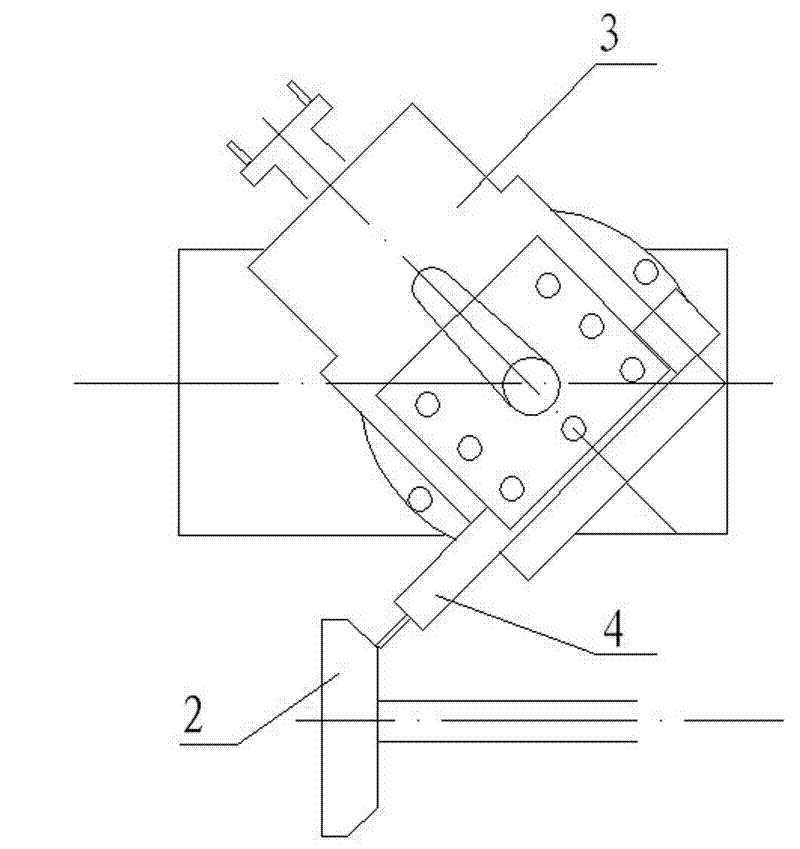

[0015] ① First, install the grinding wheel dresser diamond pen 4 on the small bracket 3 of the lathe, and adjust the angle to dress the side of the grinding wheel 2, see figure 2 .

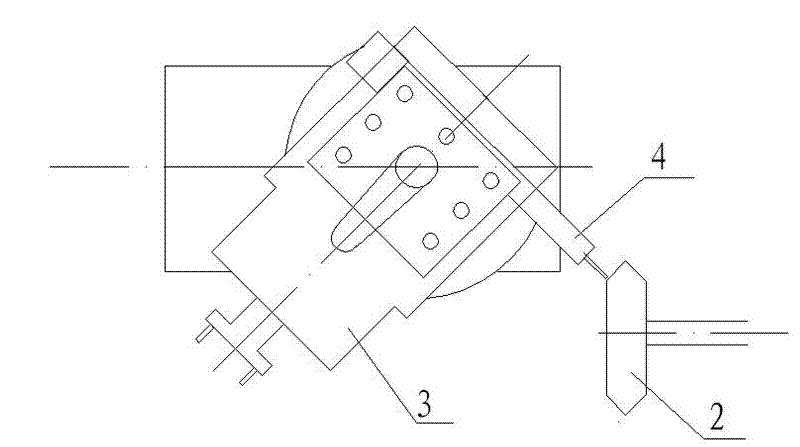

[0016] ② Rotate the small bracket 3 by 90 degrees, then trim the other side of the grinding wheel 2, and trim the grinding wheel 2 to an outer diameter with an included angle of 90 degrees, see image 3 .

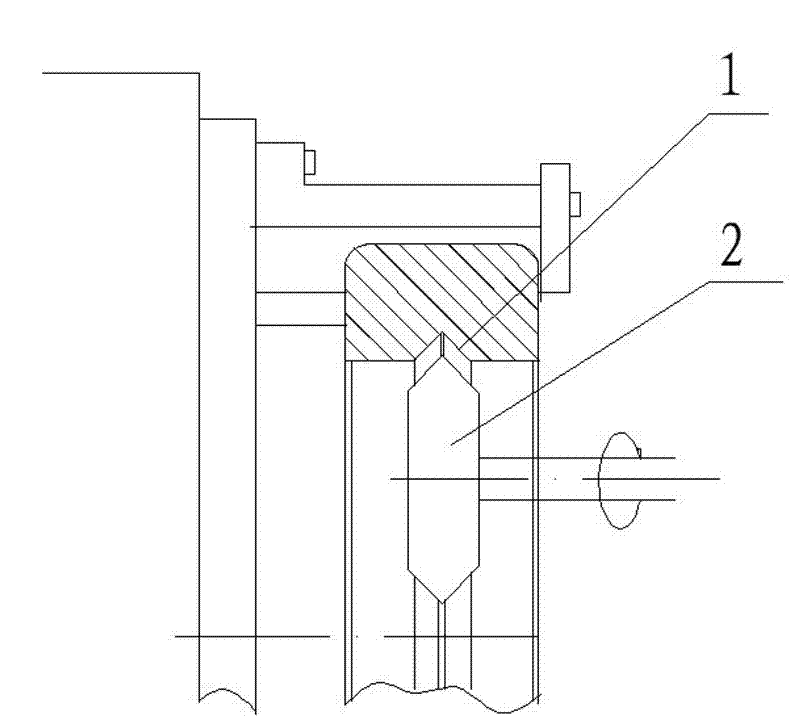

[0017] ③ Grind the right-angle raceway 1 with a grinding wheel 2 trimmed at an angle of 90 degrees, see figure 1 . One-time grinding of double grooves can be realized, so as to ensure the processing accuracy of right-angle raceways.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap