Hot-melting type filling paste for electric cable and preparation method thereof

A hot-melt, paste-filled technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of strong humidity of cables, cable transmission characteristics, insulation damage, etc., and achieve good compatibility, excellent colloidal stability and oxidation. Effects of stability, excellent electrical and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

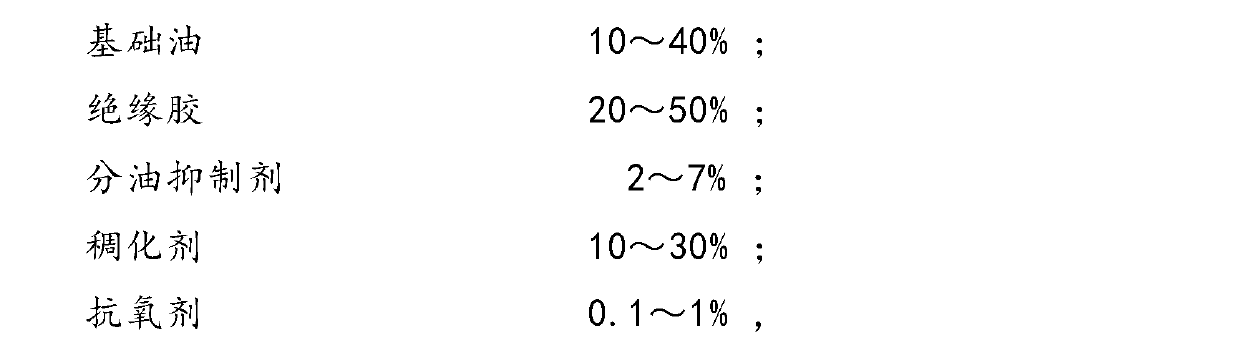

Method used

Image

Examples

Embodiment 1

[0020] Add 40 grams of EPDM rubber to 356 grams of naphthenic rubber oil, heat and stir for 3 to 5 hours, stop heating when the temperature rises to 200 ° C, keep stirring for 1 to 3 hours, and wait for the EPDM After the propylene rubber is completely melted in the naphthenic rubber oil, add 350 grams of polyisobutylene, and the temperature is controlled at 130 ° C ~ 170 ° C; after fully stirring for 1 to 3 hours, add 250 grams of refined polyethylene wax, and then keep warm (150 ± 10 ℃) after stirring for 1 to 3 hours, add 4 grams of high-temperature antioxidant, and then fully feed back and stir for 0.5 to 1 hour, then filter and cool to normal temperature, and the final product obtained is a white semi-solid.

[0021] Among the above-mentioned raw materials, the high-temperature antioxidant is selected from Ciba Specialty Chemicals (China) Co., Ltd., the product model is B225, and other raw materials are all commercially available products.

[0022] The main indicators of ...

Embodiment 2

[0024] Add 45 grams of EPDM rubber to 340 grams of hydrogenated white oil, heat and stir for 3 to 5 hours, when the temperature rises to 200 ° C, stop heating, keep stirring for 1 to 3 hours, and wait for the EPDM After the rubber is completely melted in the hydrogenated white oil, add 360 grams of polybutene, and the temperature is controlled at 130 ° C ~ 170 ° C; after fully stirring for 1 to 3 hours, add 250 grams of refined polyethylene wax, and then keep warm (150 ± 10 ° C ) after stirring for 1 to 3 hours, add 5 grams of high-temperature antioxidant, and then fully feed back and stir for 0.5 to 1 hour, then filter and cool to normal temperature, and the final product obtained is a white semi-solid.

[0025] Among the above-mentioned raw materials, the high-temperature antioxidant is the same as in Example 1, and the other raw materials are all commercially available products.

[0026] The main indicators of the final product after testing are: appearance (white semi-soli...

Embodiment 3

[0028] Add 50 grams of EPDM rubber to 350 grams of naphthenic rubber oil, heat and stir for 3 to 5 hours, stop heating when the temperature rises to 200 ° C, keep stirring for 1 to 3 hours, and wait for the EPDM After the propylene rubber is completely melted in the naphthenic rubber oil, add 340 grams of polybutene, and the temperature is controlled at 130 ° C ~ 170 ° C; after fully stirring for 1 to 3 hours, add 255 grams of refined polyethylene wax, and then keep warm (150 ± 10° C.) after stirring for 1 to 3 hours, add 5 grams of high-temperature antioxidant, and then fully feed back and stir for 0.5 to 1 hour, then filter and cool to normal temperature, and the final product obtained is a white semi-solid.

[0029] Among the above-mentioned raw materials, the high-temperature antioxidant is the same as in Example 1, and the other raw materials are all commercially available products.

[0030] The main indicators of the final product after testing are: appearance (white sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com