Carbon nano tube/polymer/semiconductor nano particle composite material and preparation method thereof

A nanocomposite, carbon nanotube technology, applied in shielding, nuclear engineering, reactors, etc., to achieve good optical limiting performance, simple operation, and enhanced dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

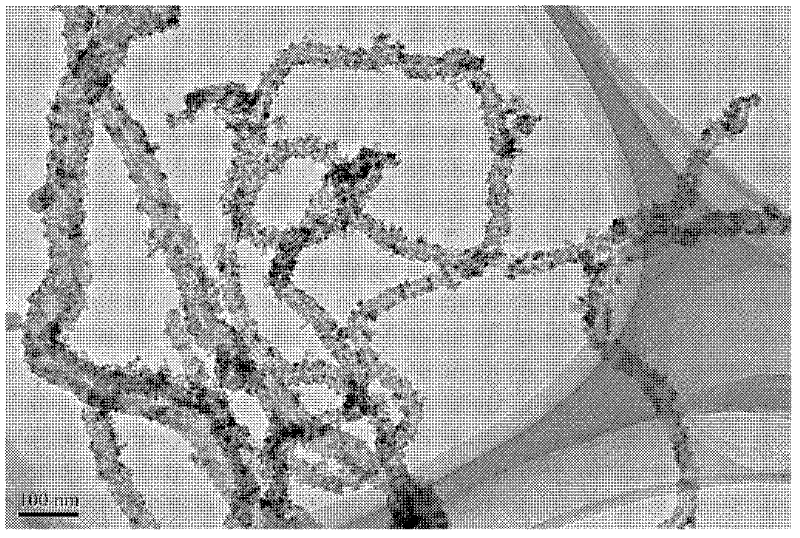

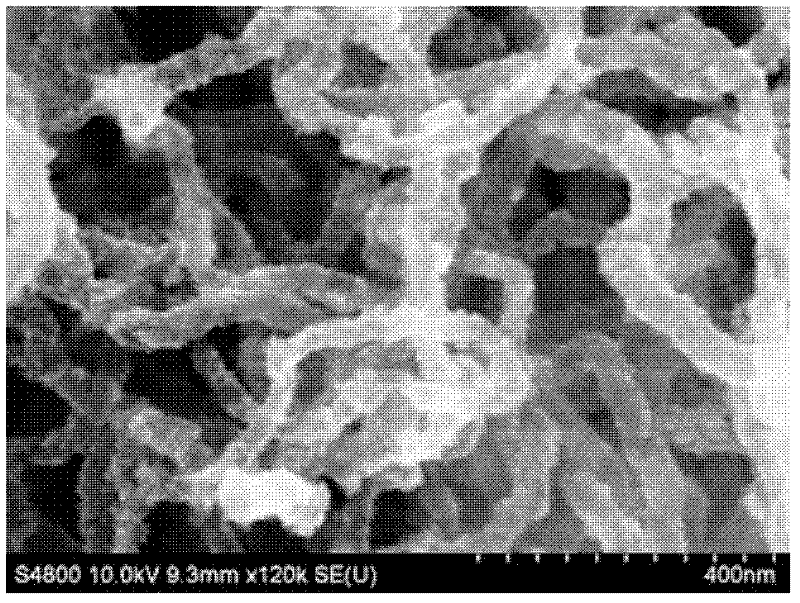

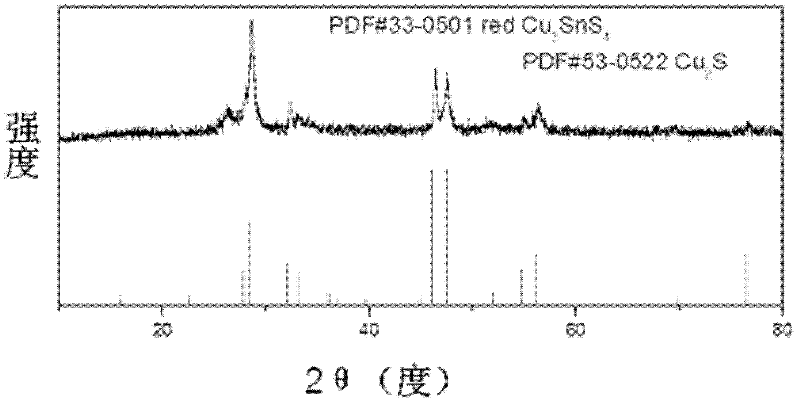

Image

Examples

Embodiment 1

[0027] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0028] b) 30mg of multi-walled carbon nanotubes were added to the above solution, and ultrasonicated for 2h;

[0029] c) centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0030] d) Disperse the centrifugal precipitate obtained above in 30 mL of ethanol, ultrasonicate for 2 h, and add 0.9 mmol CuCl to it 2 ·2H 2 O and 0.3 mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O species is 3:1. Magnetic stirring at room temperature for 10 min to make Cu 2+ and Sn 2+ Fully adsorbed on carbon nanotubes;

[0031] e) 30mL of thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) was added dropwise to the solution of d), continued stirring for 10min, the solution was transferred to the reaction kettle, and reacted at 200 ° C for 12h;

[0032] f) cooled to room tempera...

Embodiment 2

[0037] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0038] b) 30mg of multi-walled carbon nanotubes were added to the above solution, and ultrasonicated for 2h;

[0039] c) centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0040] d) Disperse the centrifugal precipitate obtained above in 30 mL of ethanol, ultrasonicate for 2 h, and add 0.6 mmol CuCl to it 2 ·2H 2 O and 0.6 mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O species is 1:1. Magnetic stirring at room temperature for 10 min to make Cu 2+ and Sn 2+ Fully adsorbed on carbon nanotubes;

[0041] e) 30mL of thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) was added dropwise to the solution of d), continued stirring for 10min, the solution was transferred to the reaction kettle, and reacted at 200°C for 12h;

[0042] f) cooled to room temperatu...

Embodiment 3

[0049] a) Dissolve 30 mg of sodium polystyrene sulfonate in 30 mL of ethanol;

[0050] b) 30mg of multi-walled carbon nanotubes were added to the above solution, and ultrasonicated for 2h;

[0051] c) centrifuge the solution obtained in b) and wash it with ethanol 6 times until the excess sodium polystyrene sulfonate is washed away;

[0052] d) Disperse the centrifugal precipitate obtained above in 30 mL of ethanol, ultrasonicate for 2 h, and add 0.3 mmol CuCl to it 2 ·2H 2 O and 0.9 mmol SnCl 2 ·2H 2 O, CuCl used 2 ·2H 2 O and SnCl 2 ·2H 2 The ratio of the amount of O species is 1:3. Magnetic stirring at room temperature for 10 min to make Cu 2+ and Sn 2+ Fully adsorbed on carbon nanotubes;

[0053] e) 30mL of thiourea ethanol solution (concentration 3mg / ml, thiourea 1.2mmol) was added dropwise to the solution of d), continued stirring for 10min, the solution was transferred to the reaction kettle, and reacted at 200°C for 12h;

[0054] f) cooled to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com