Patents

Literature

38results about How to "Protective nature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard disk drive medical monitor with security encryption

InactiveUS7225031B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveDrug biological activity

Owner:WESTERN DIGITAL TECH INC

Hard disk drive medical monitor with GPS

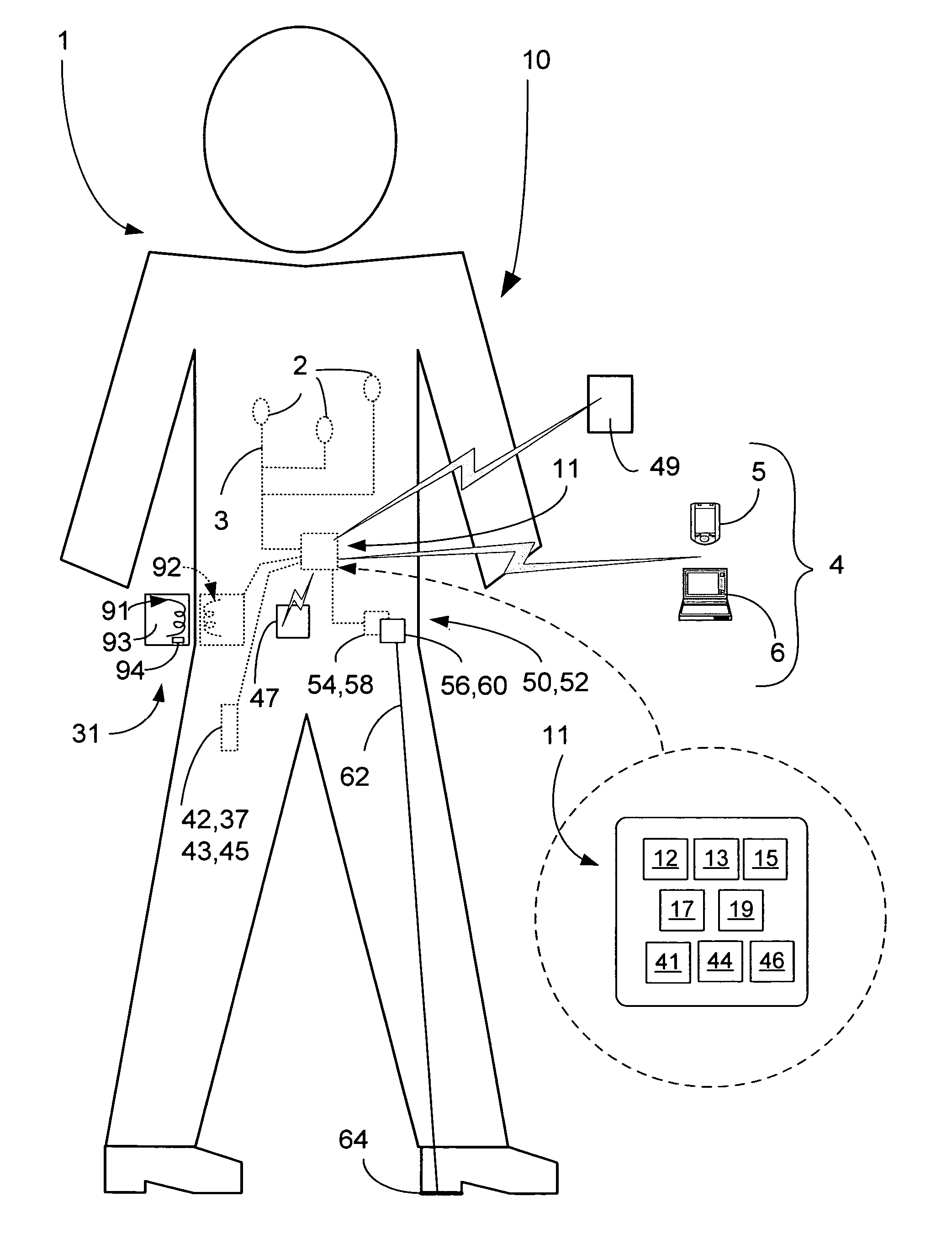

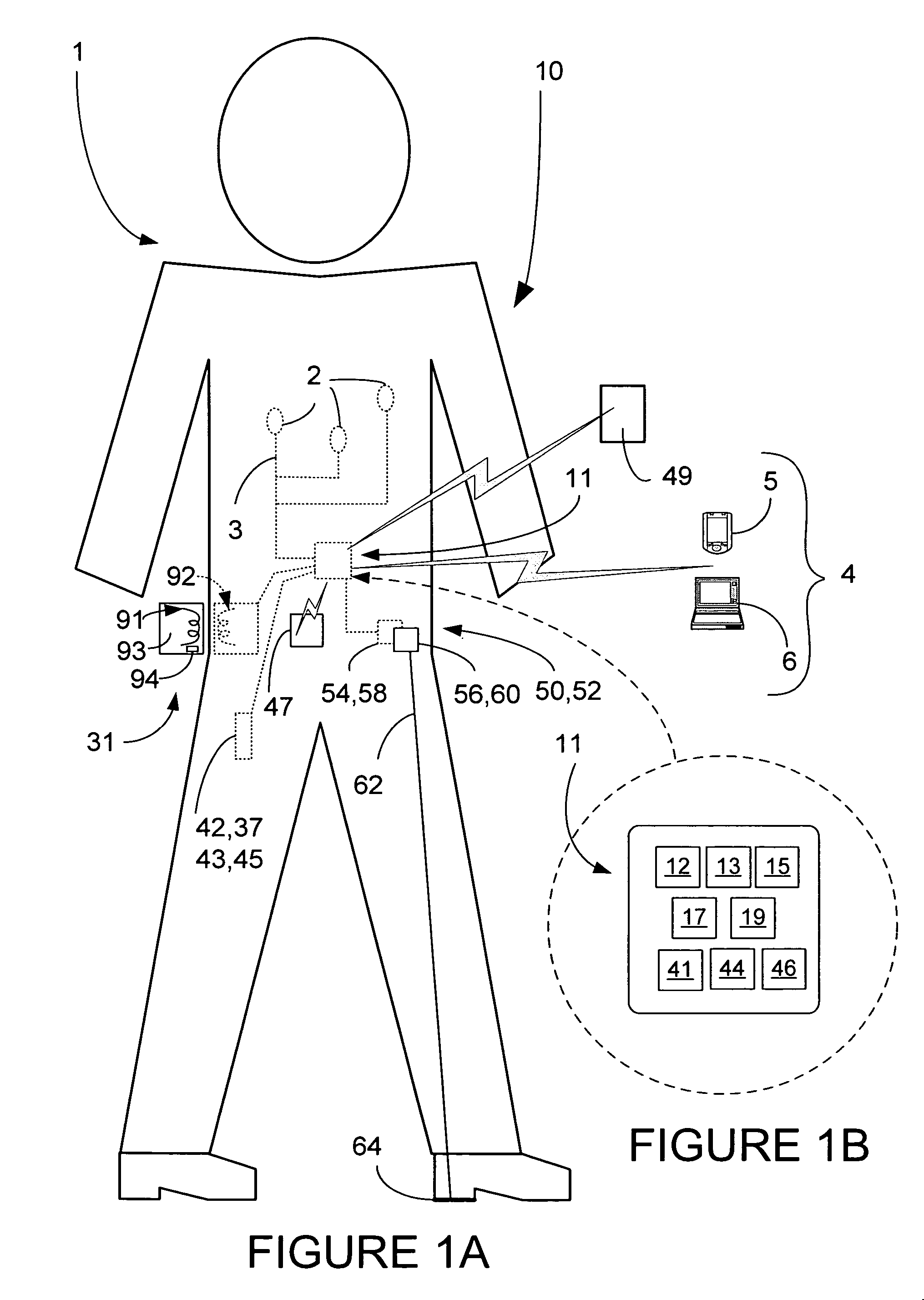

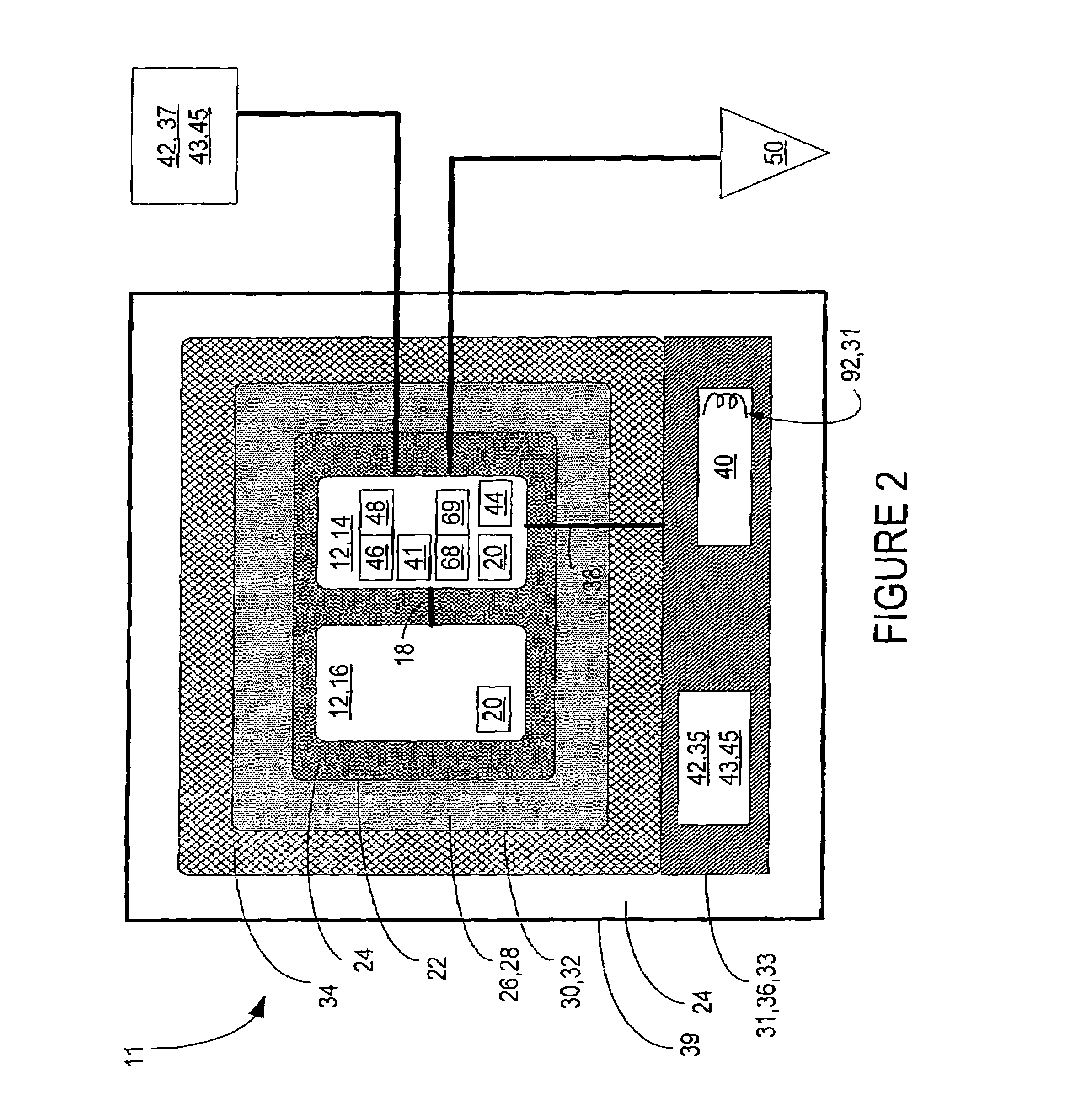

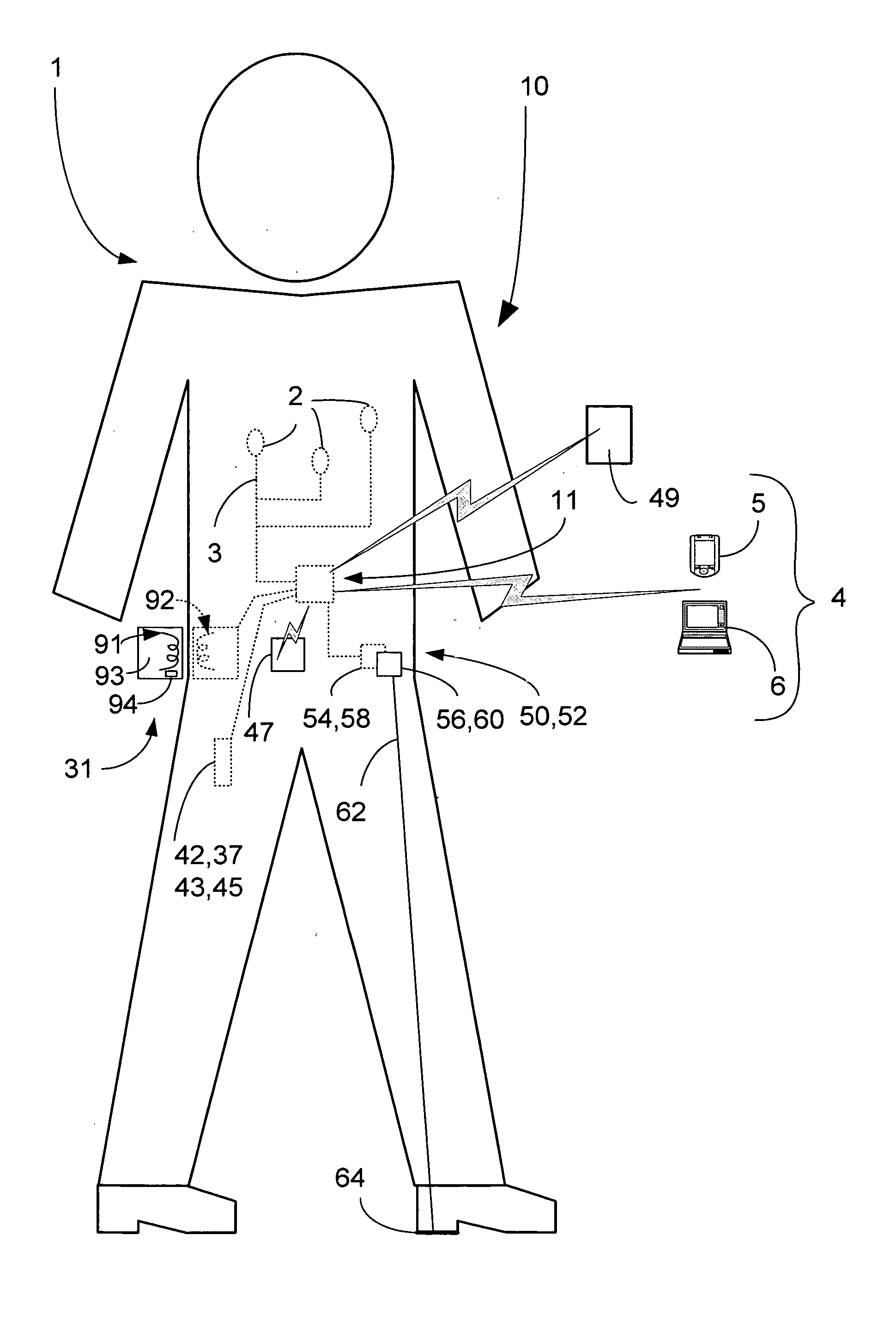

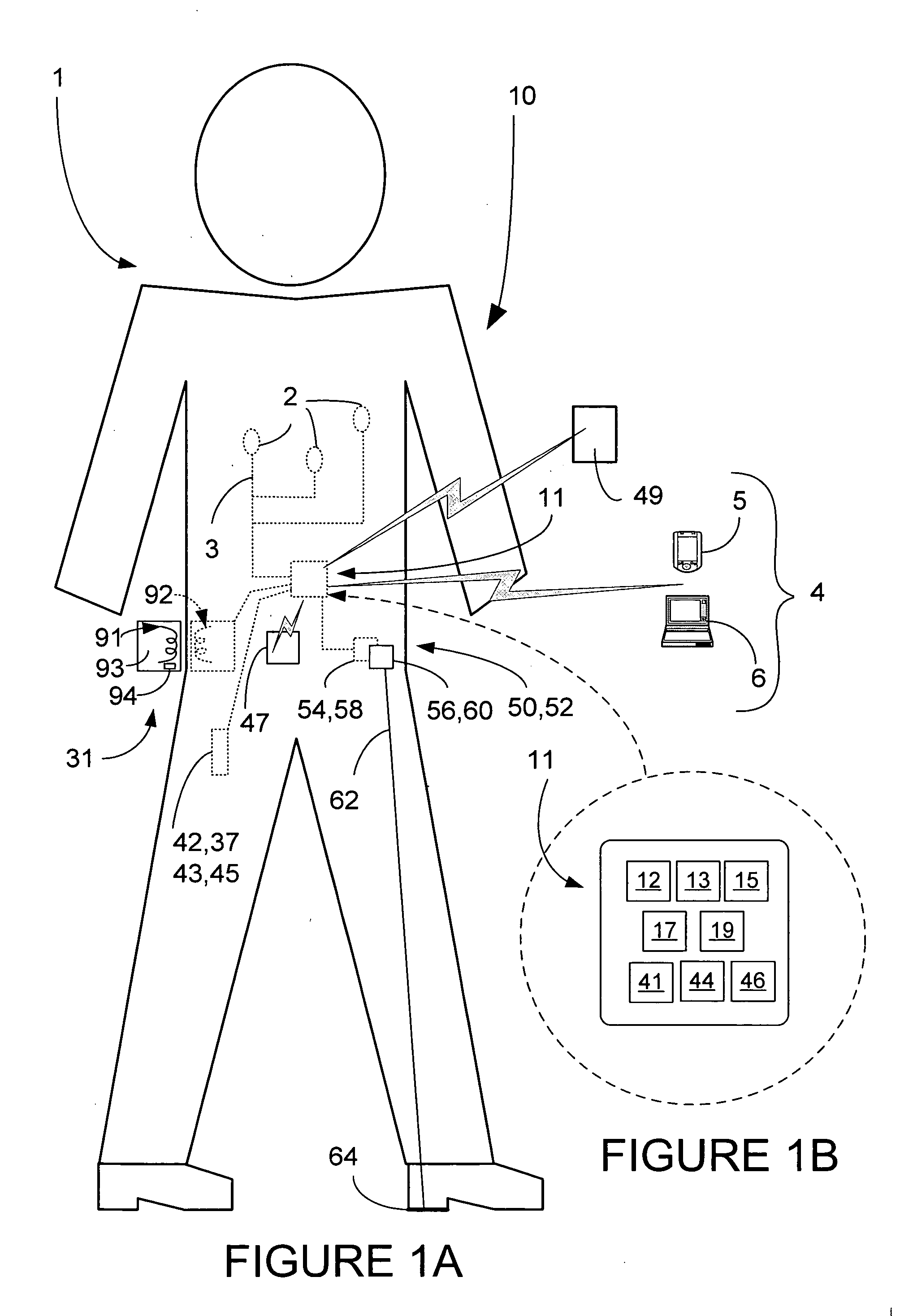

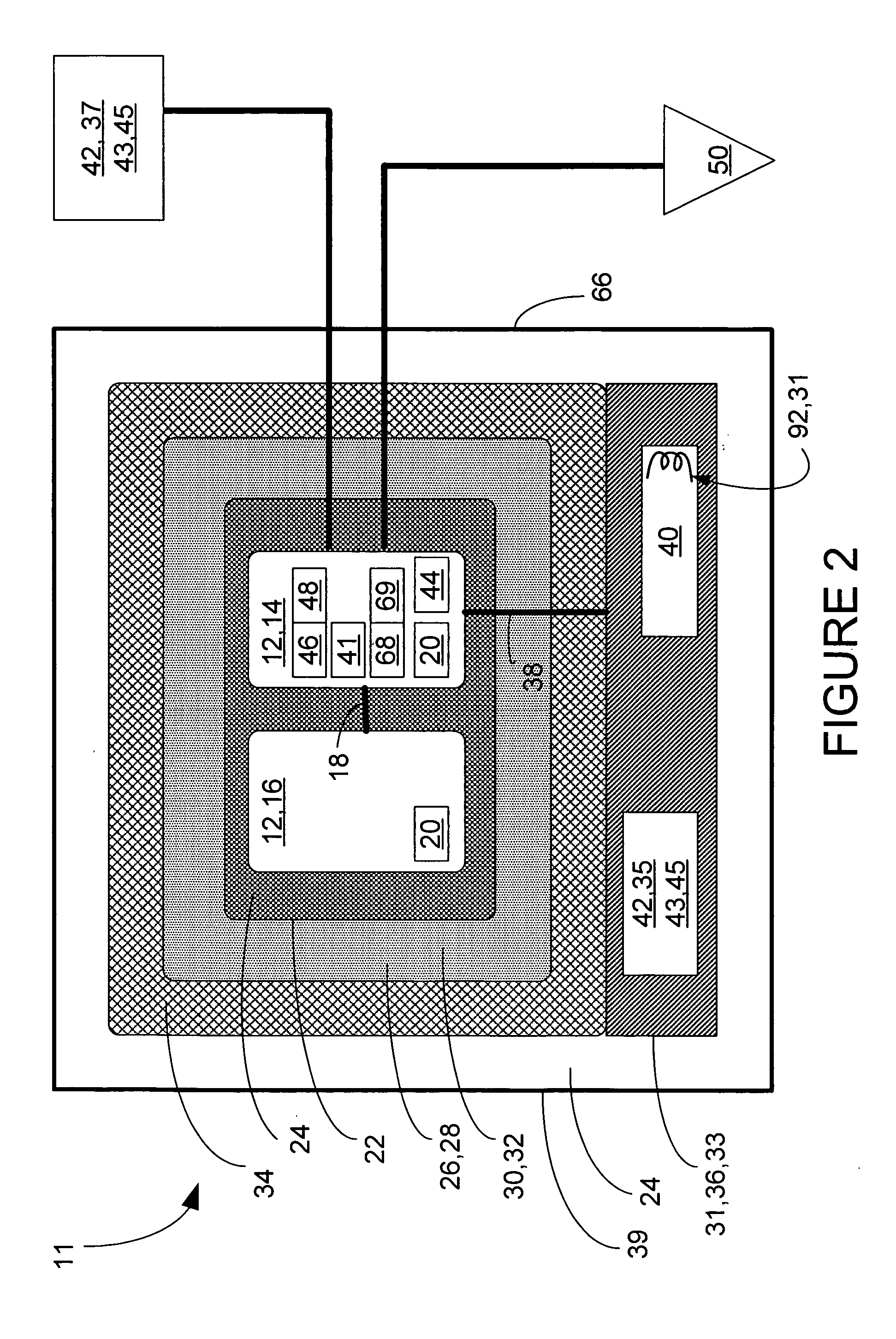

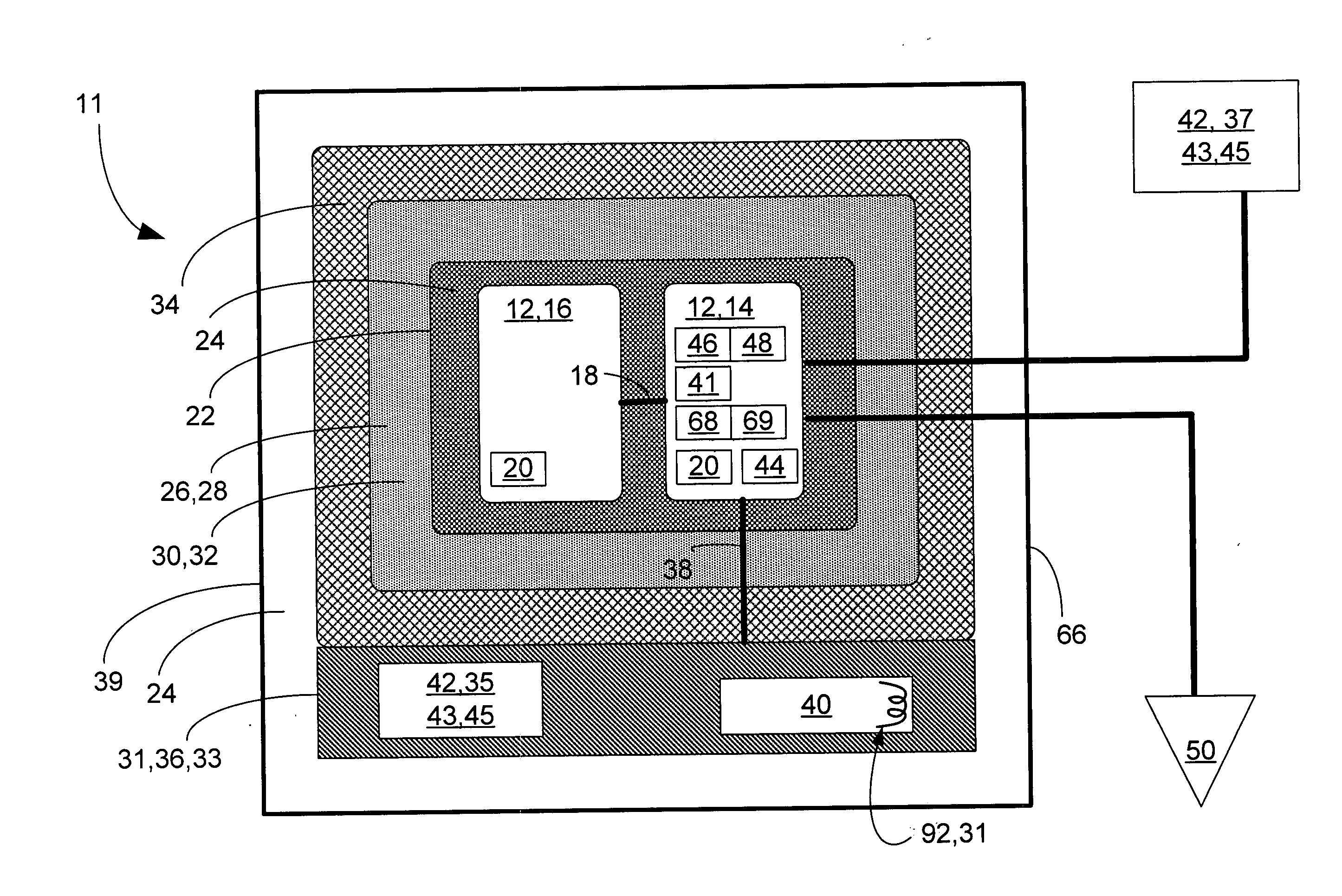

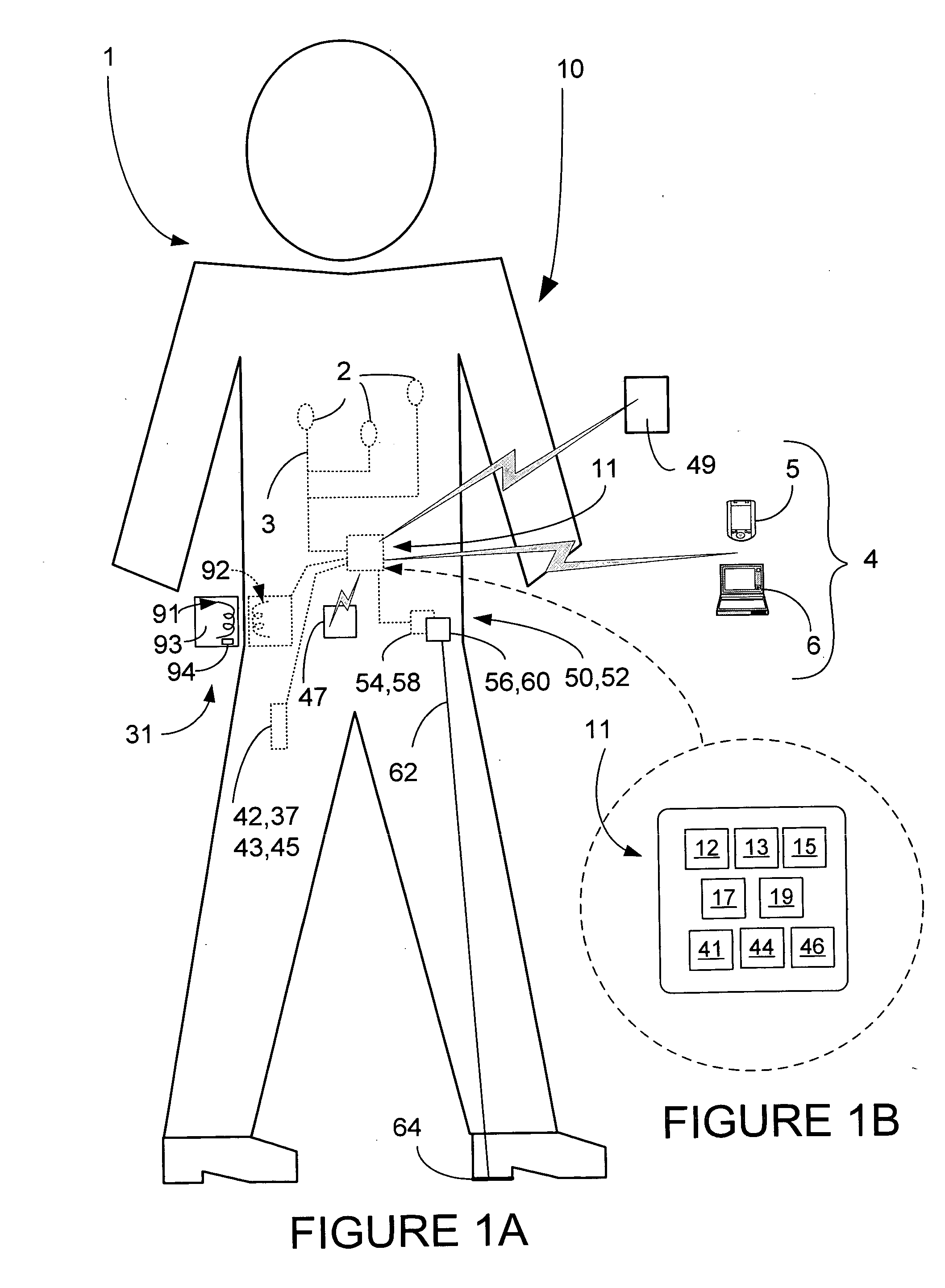

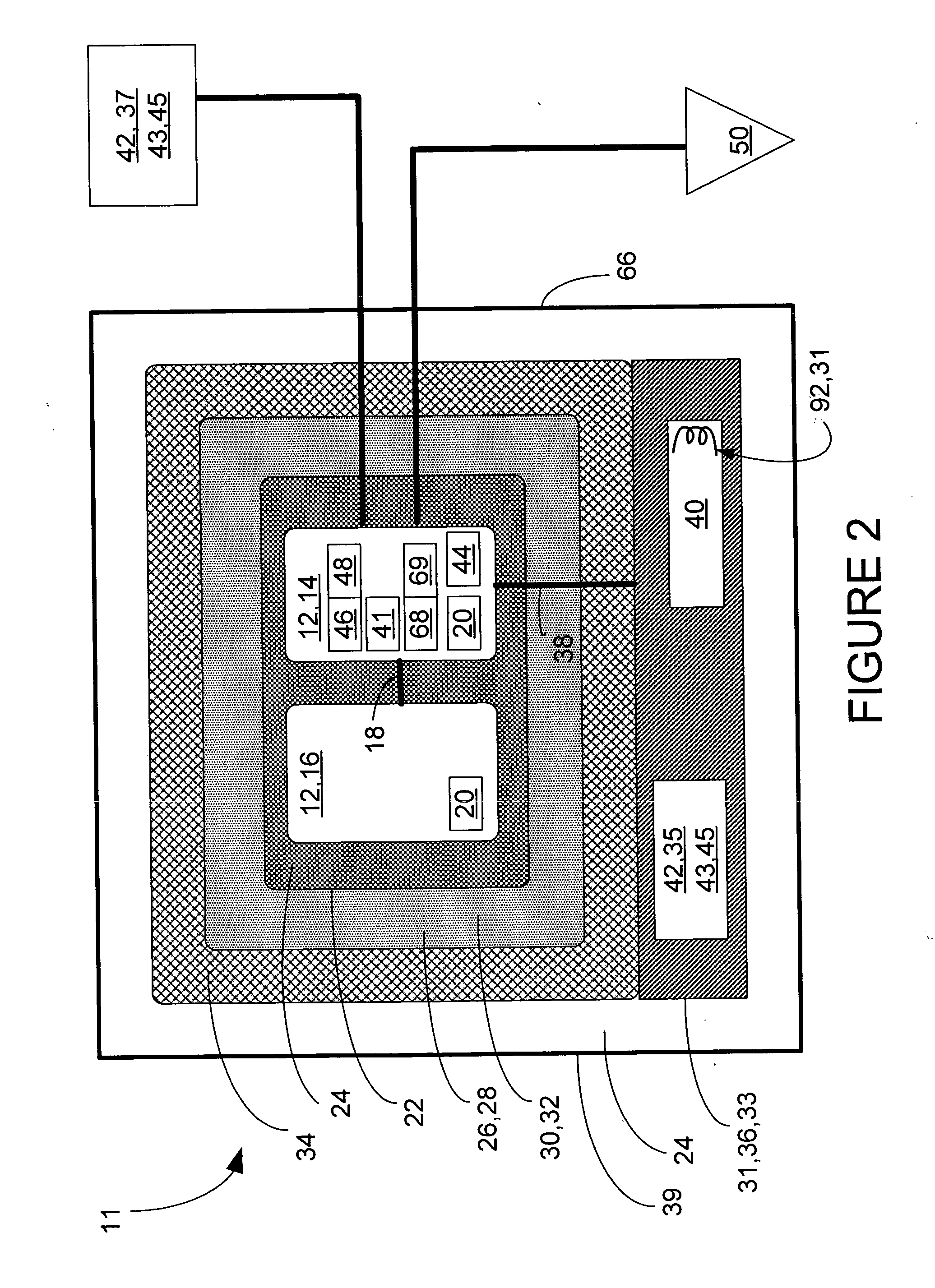

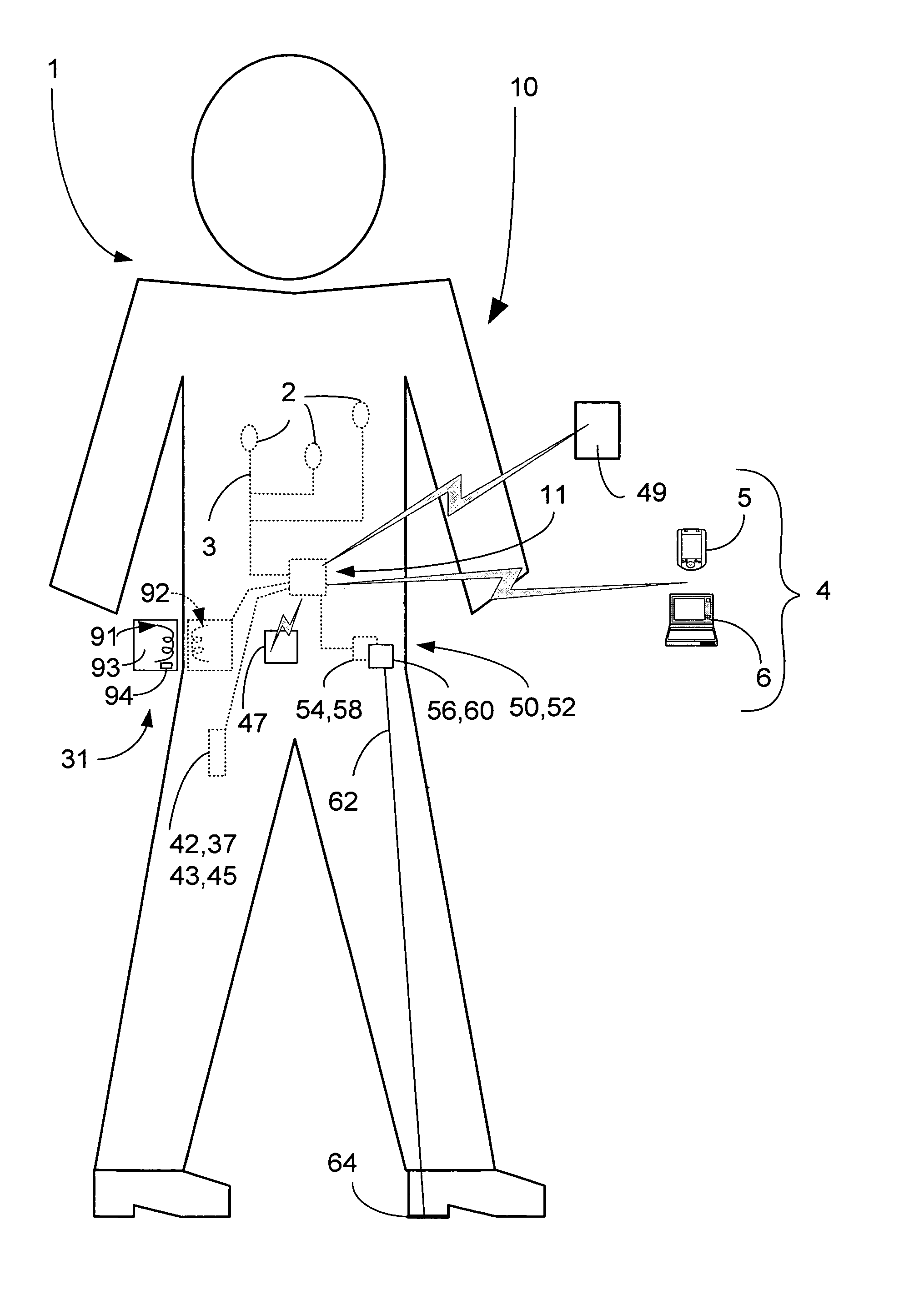

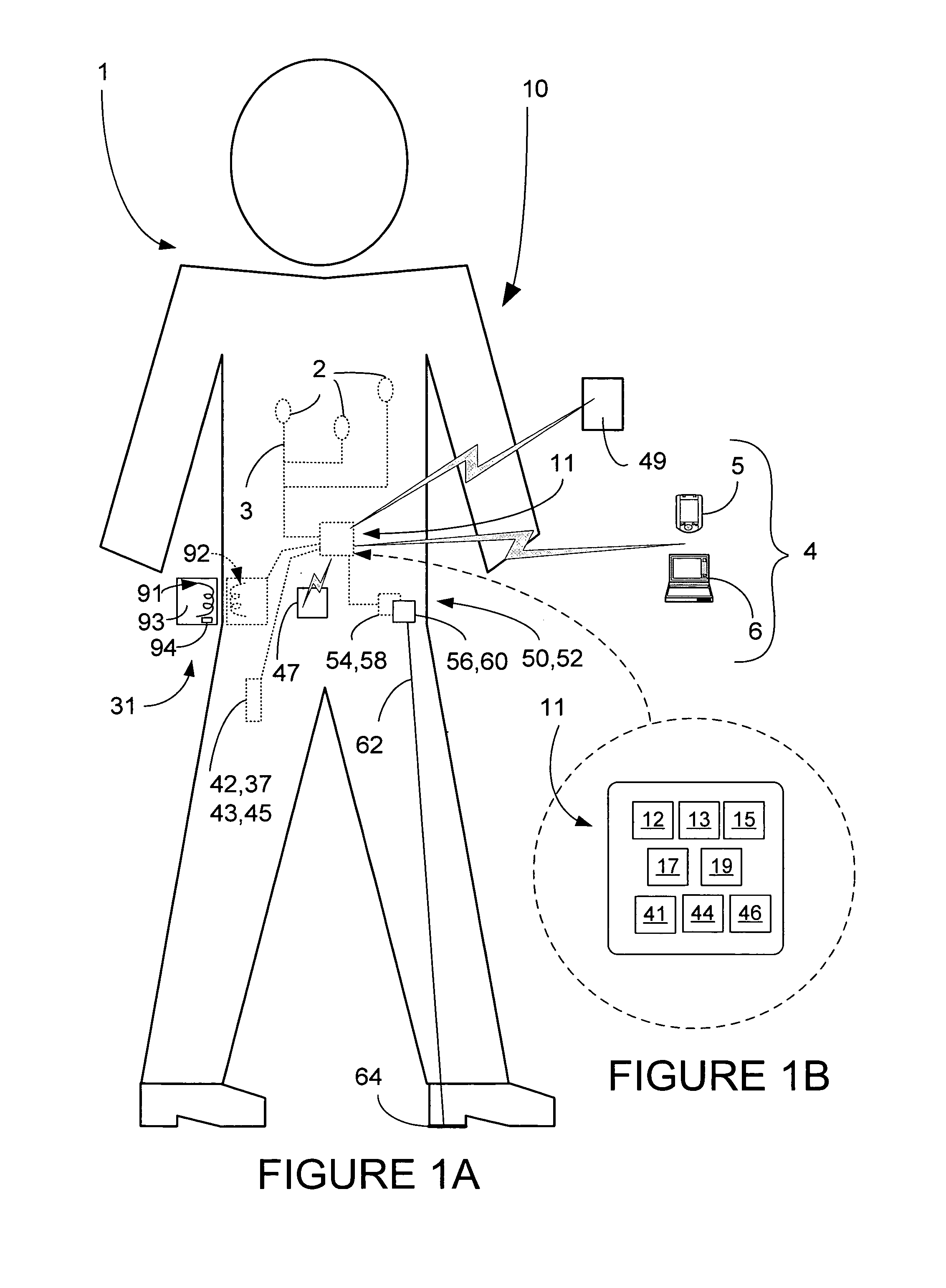

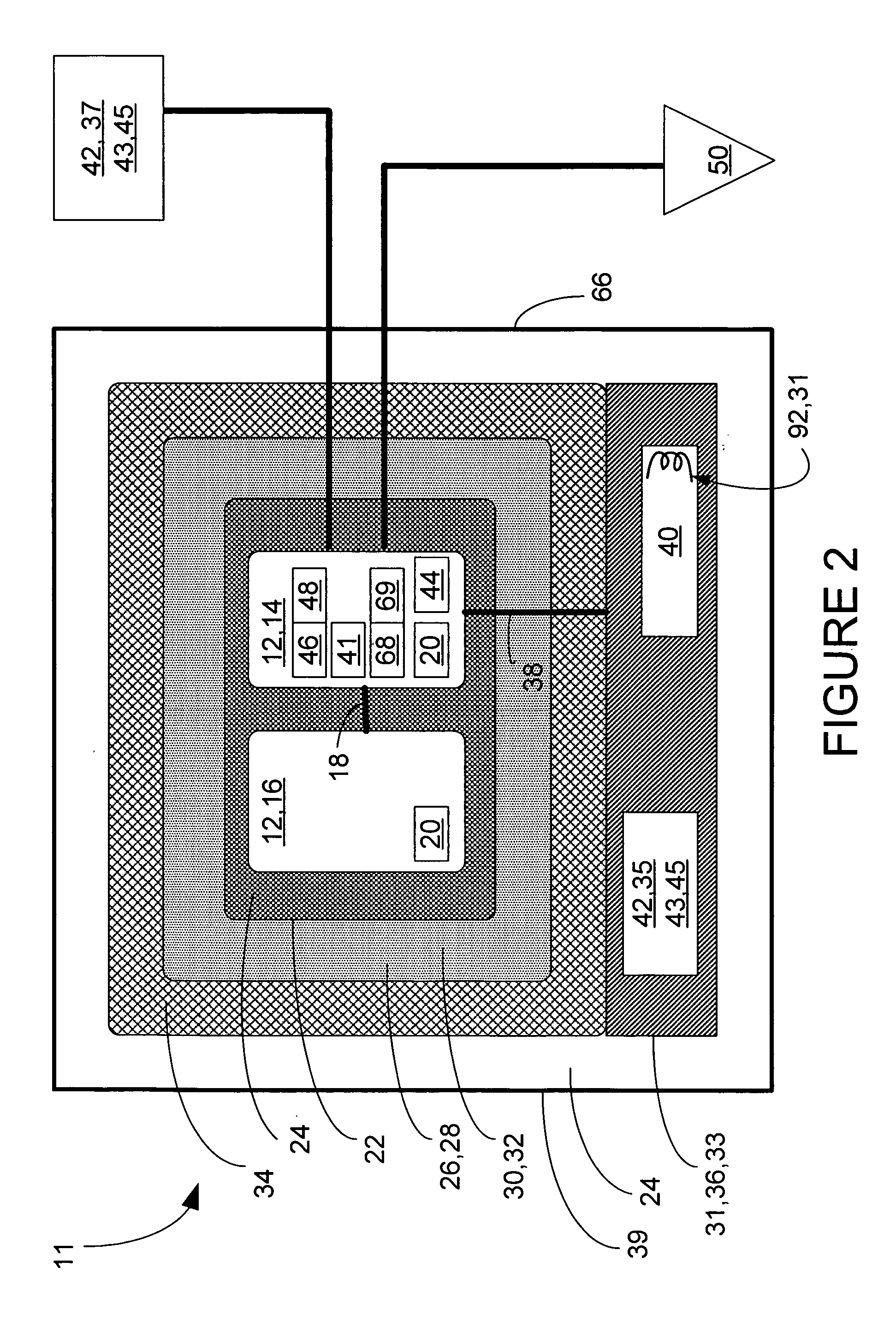

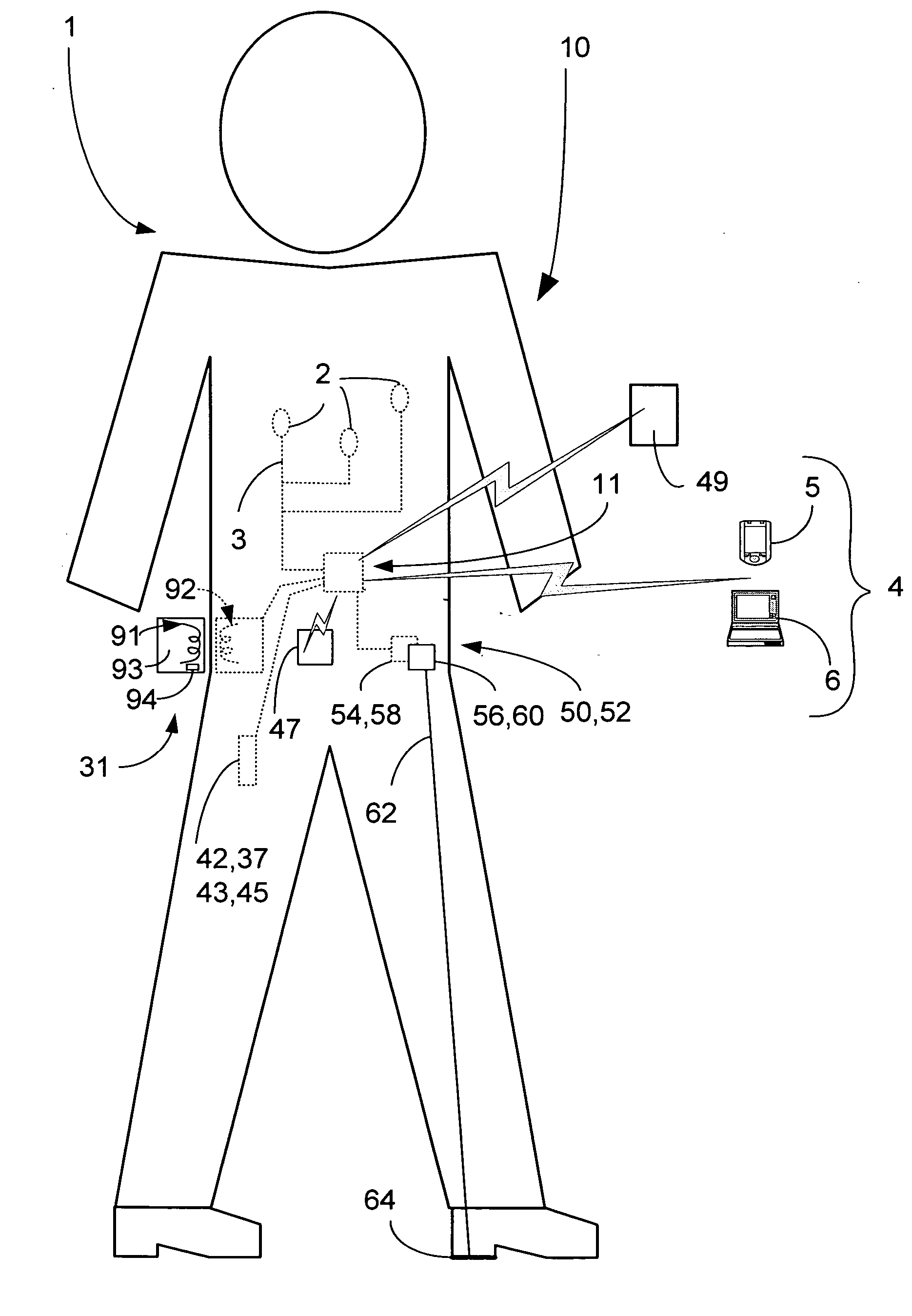

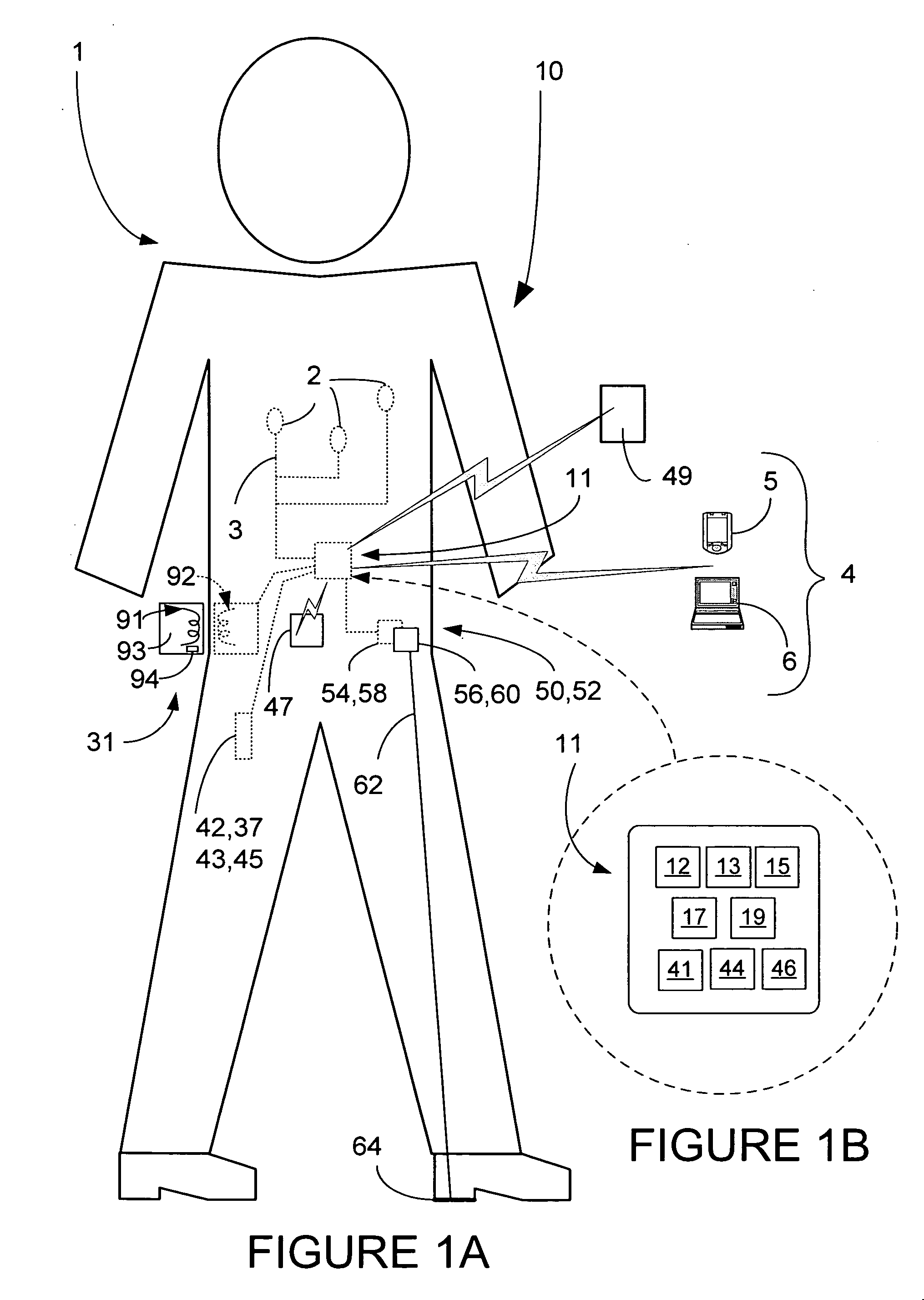

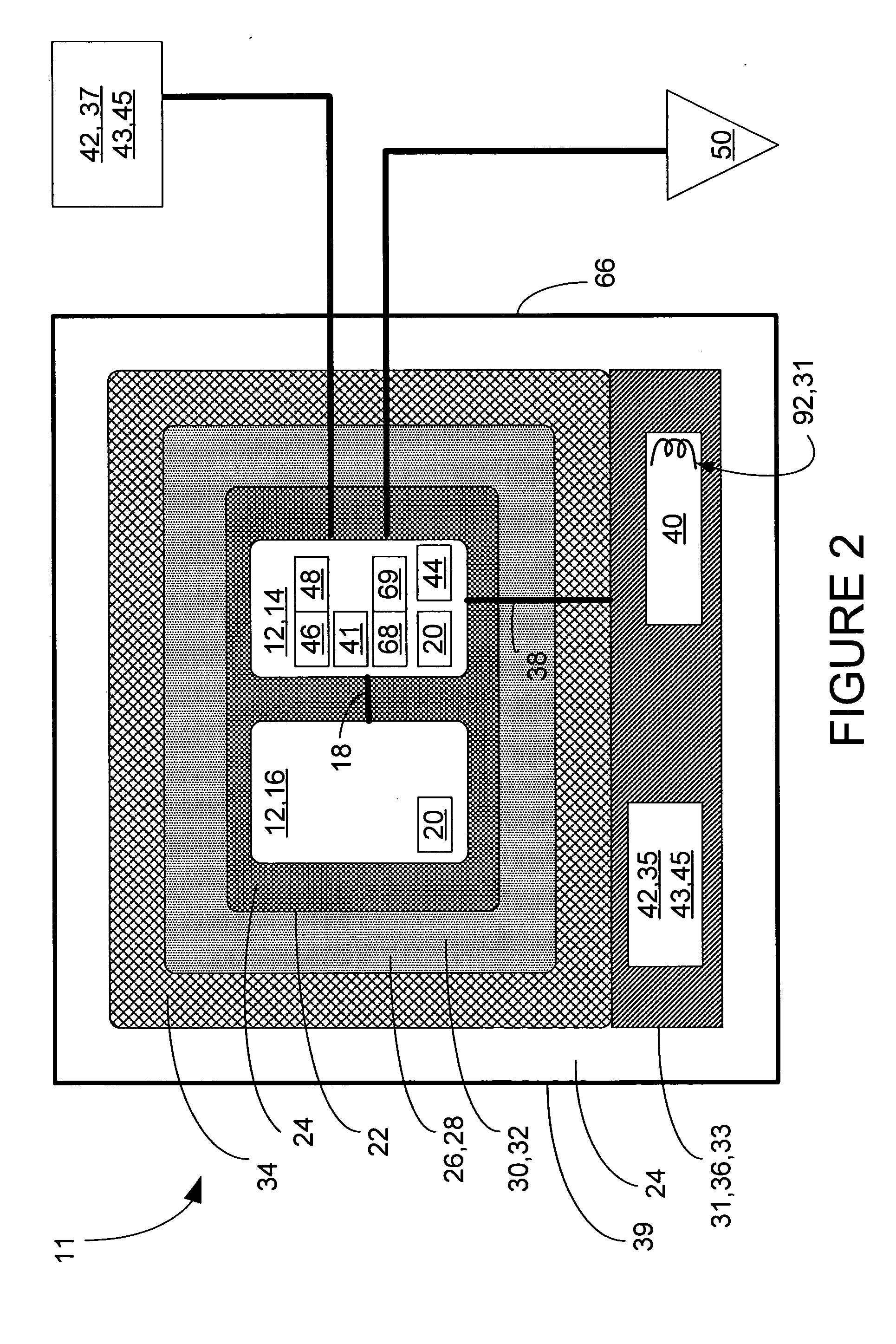

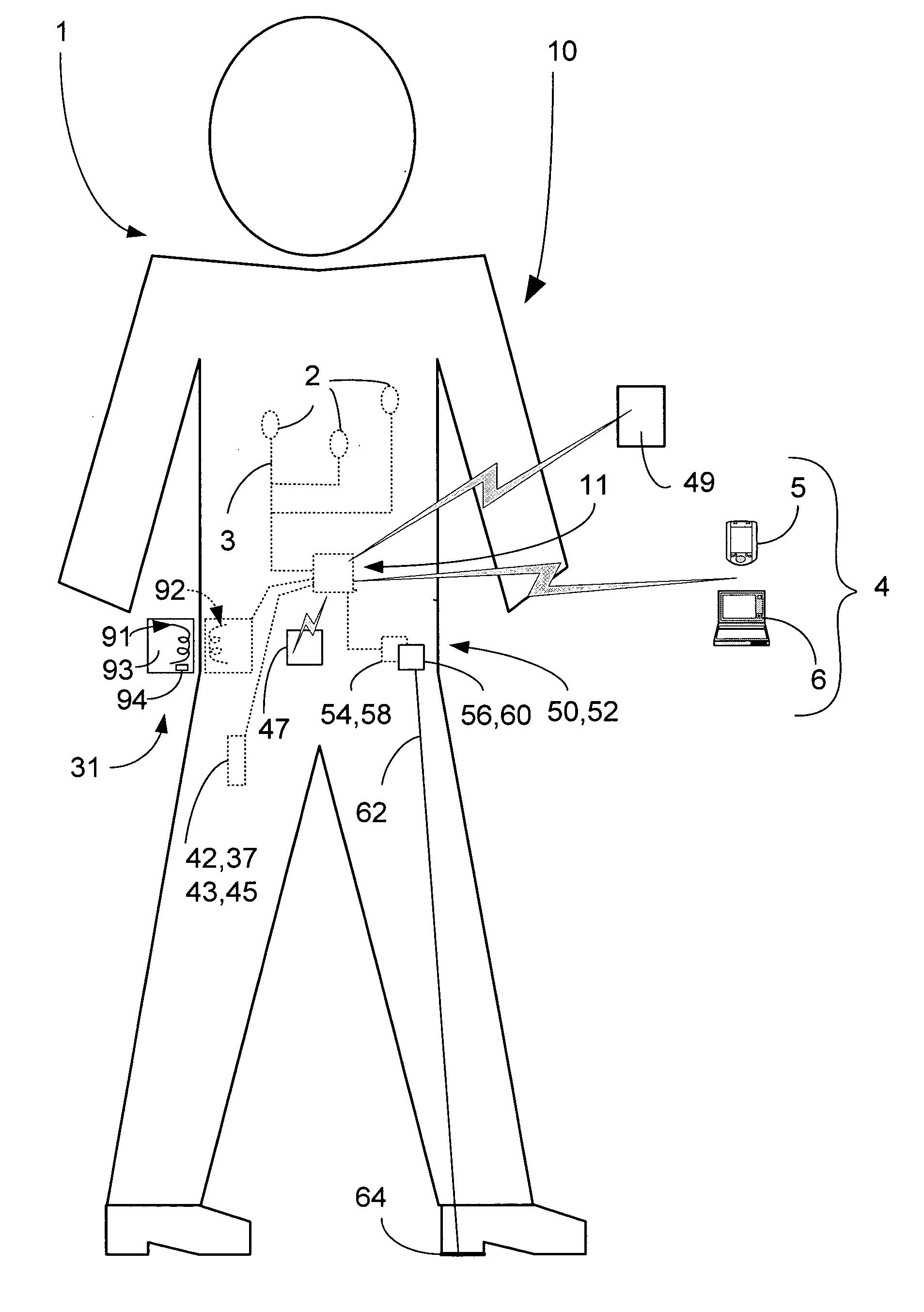

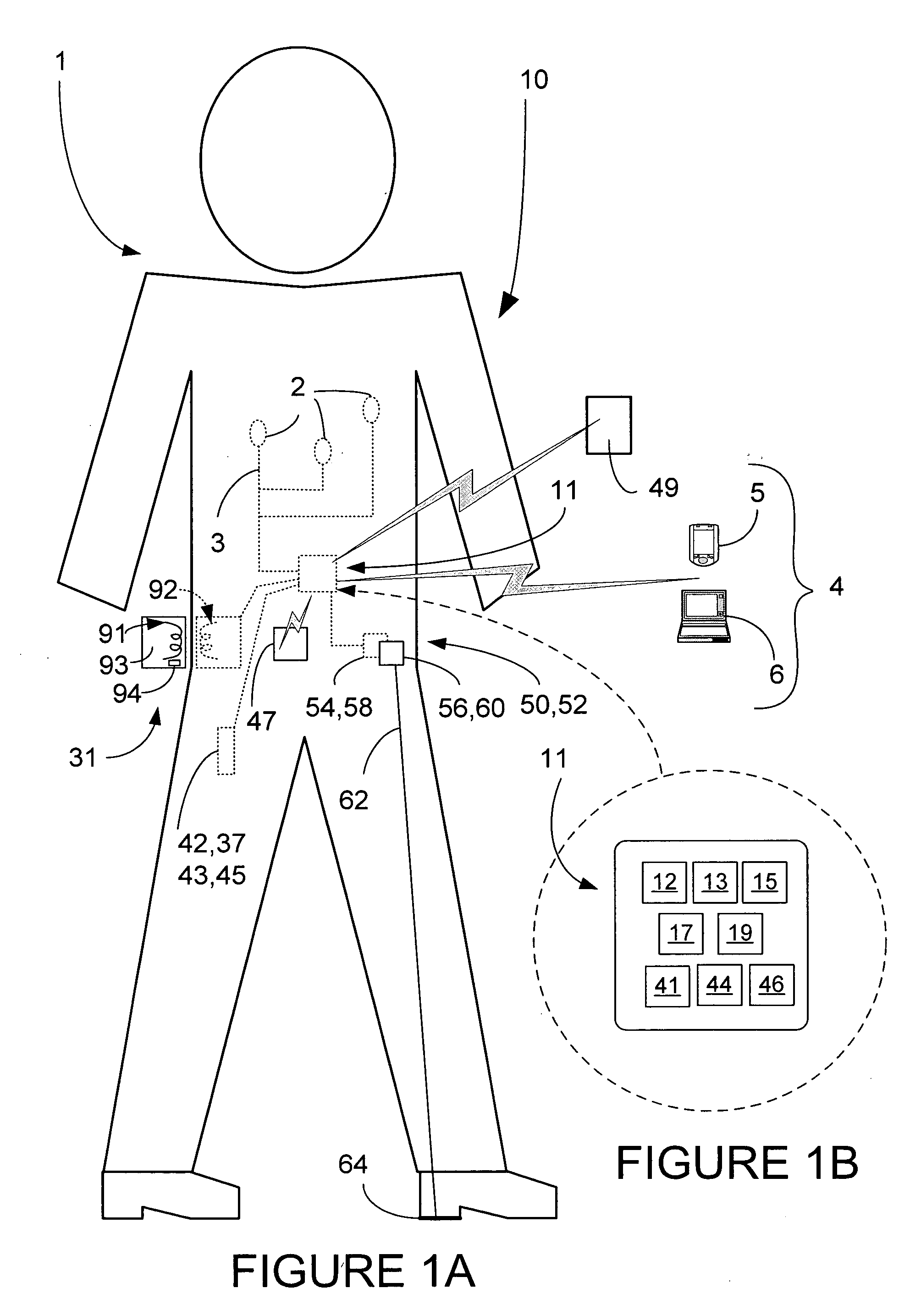

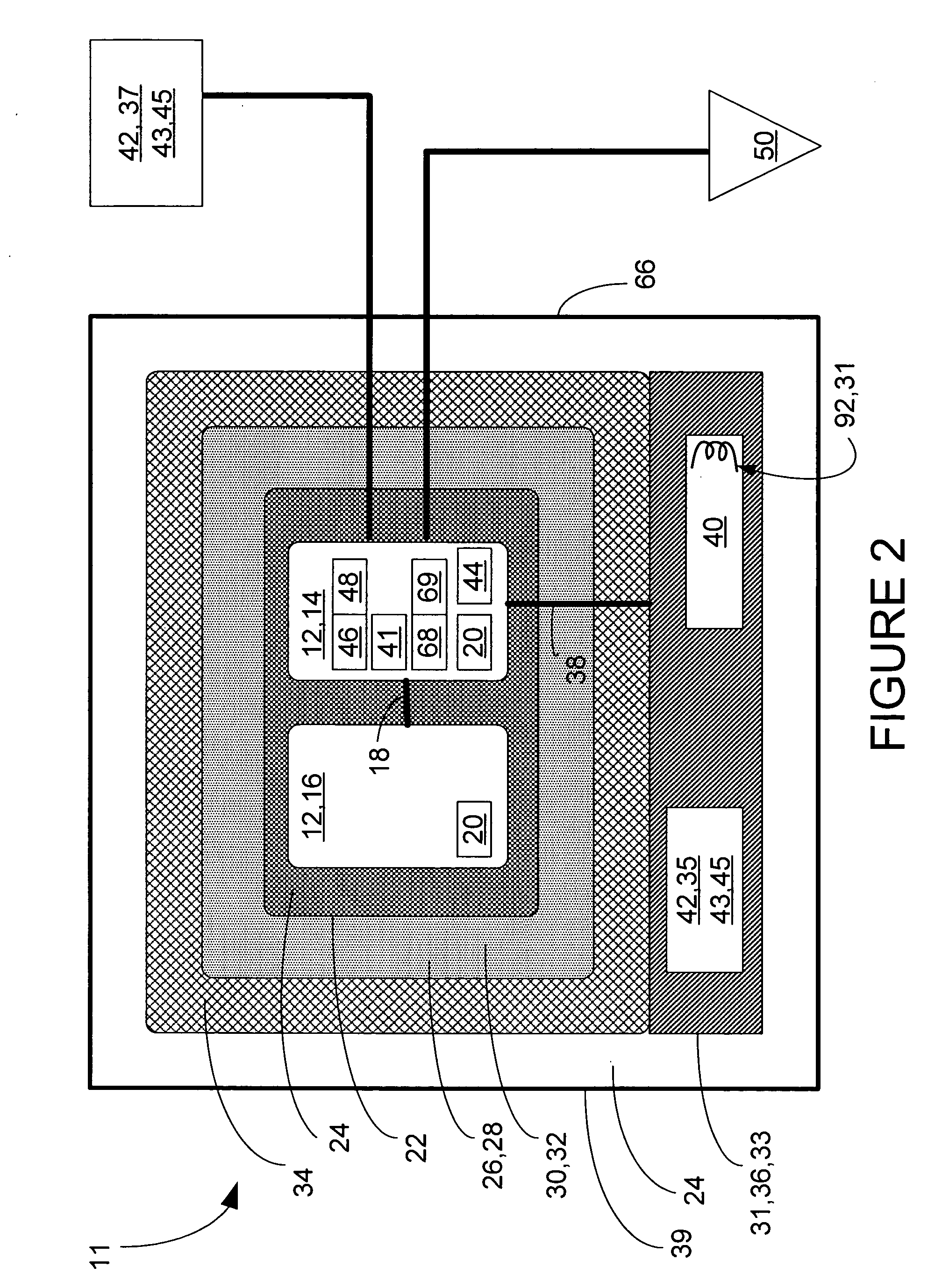

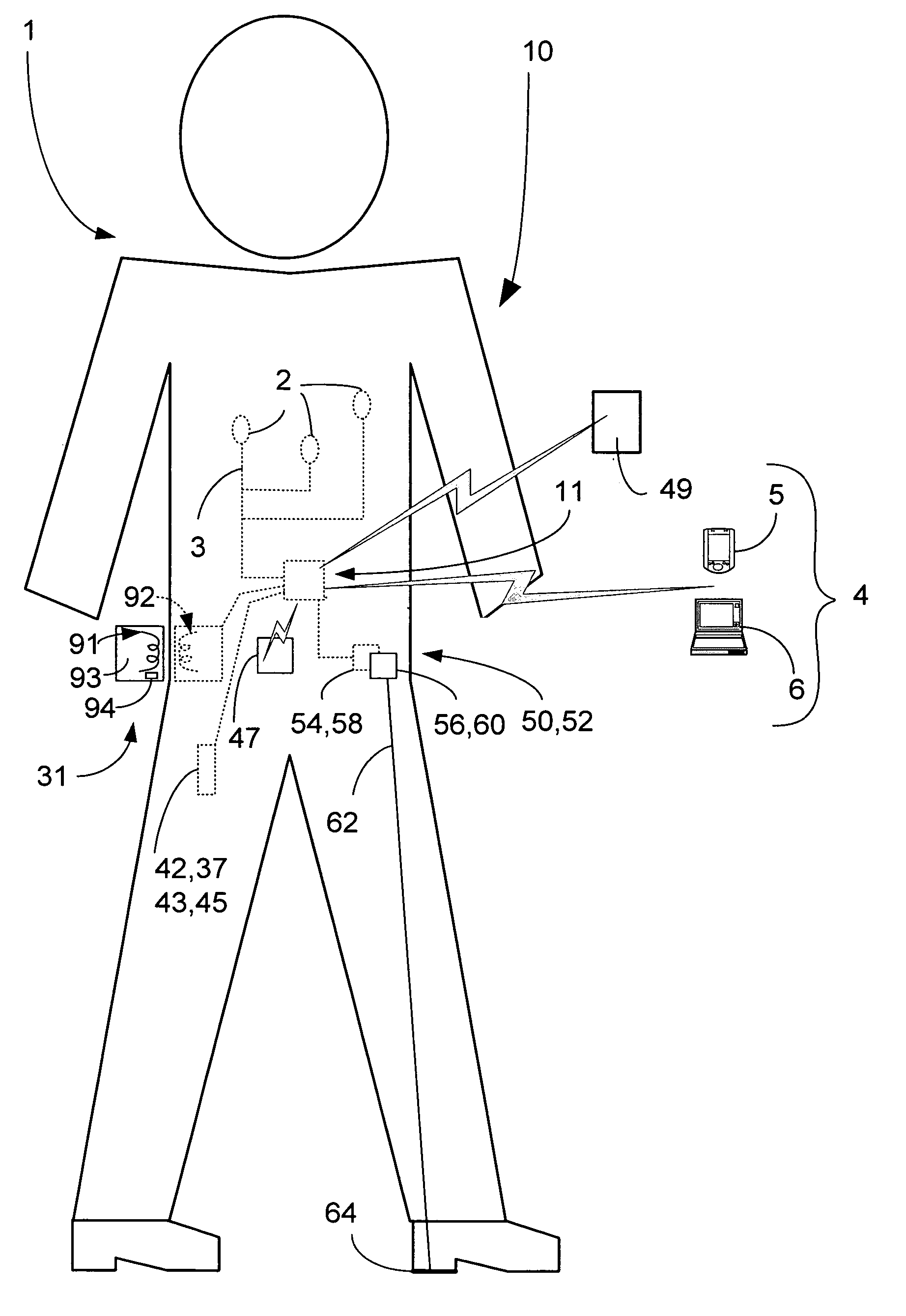

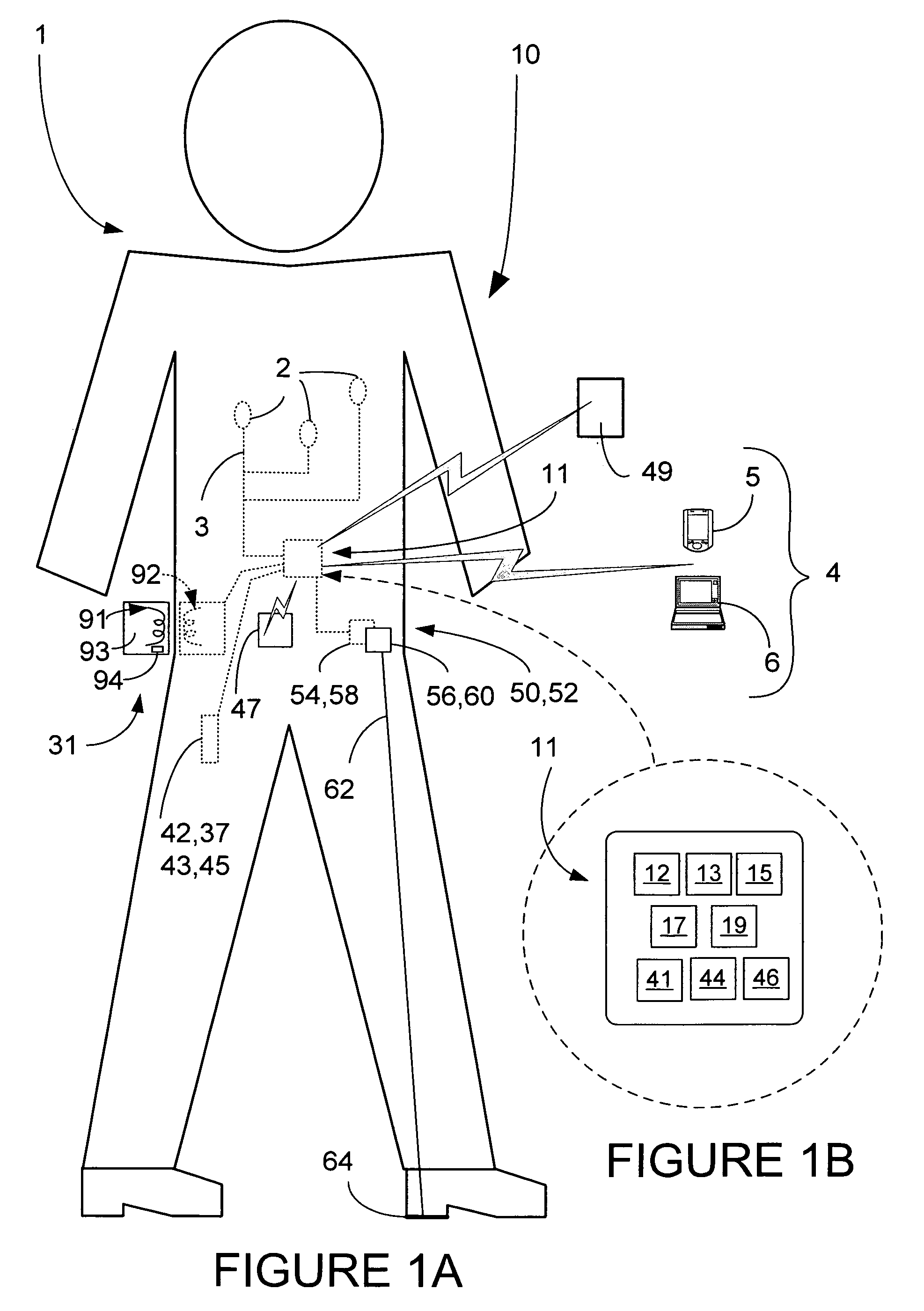

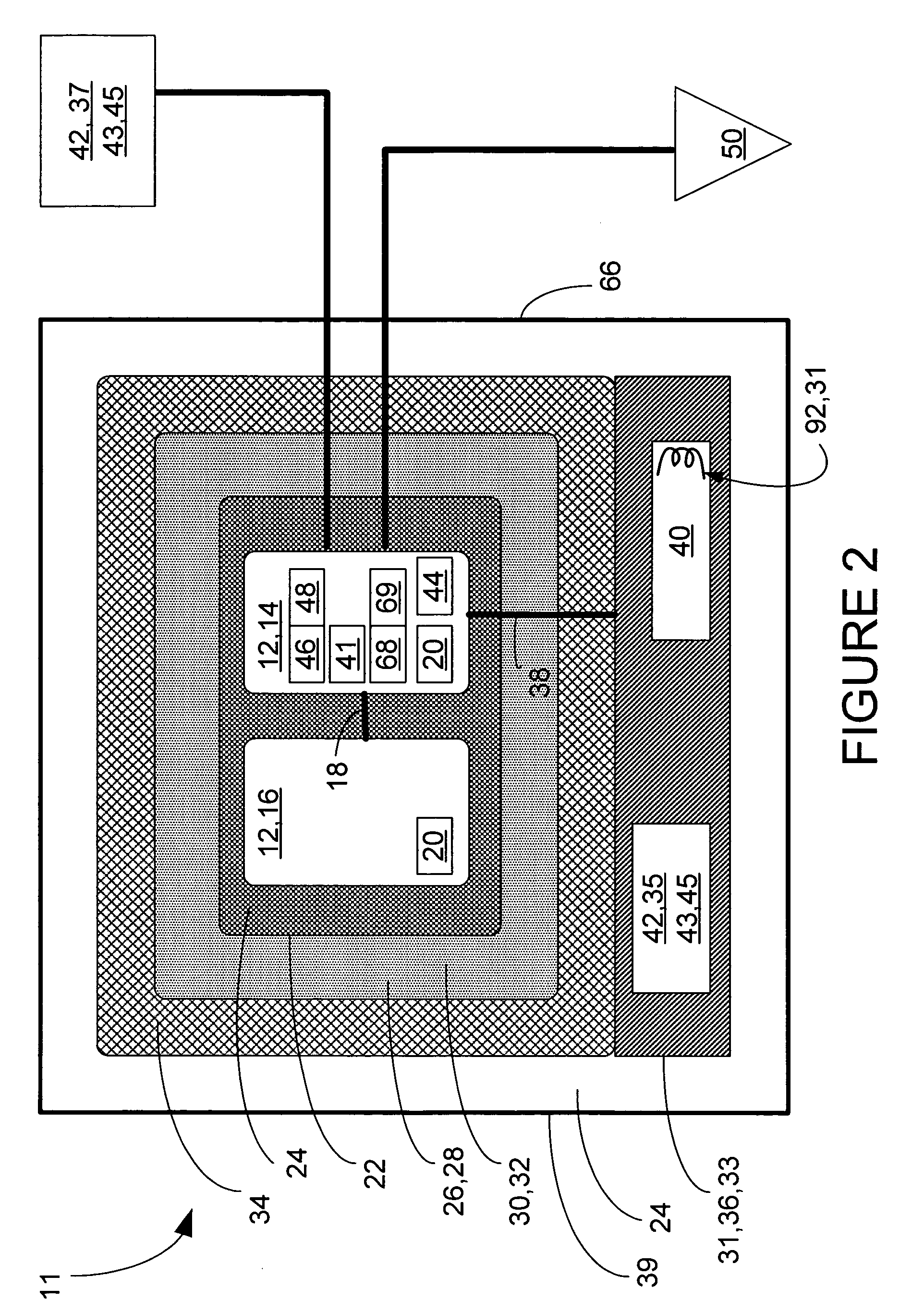

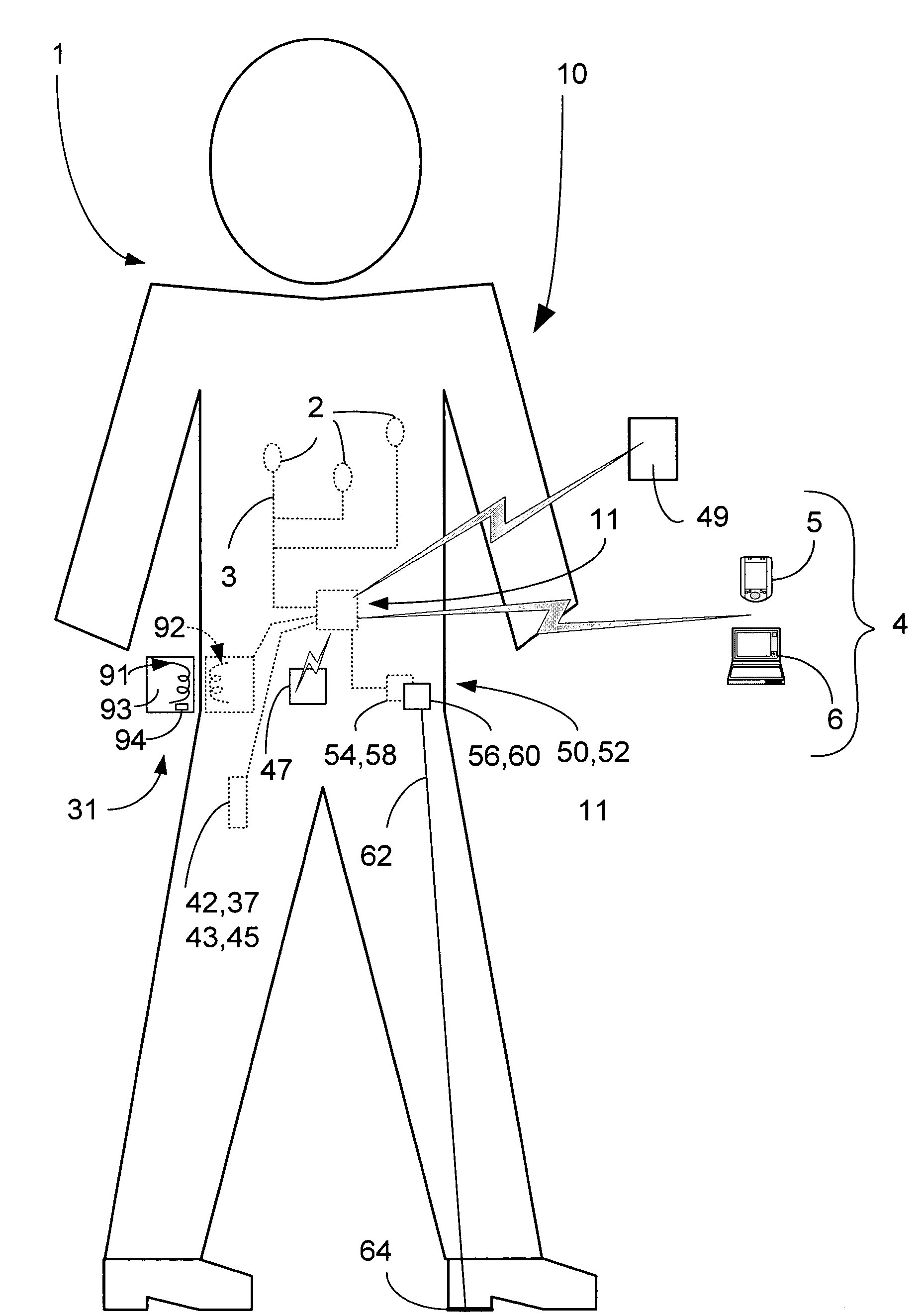

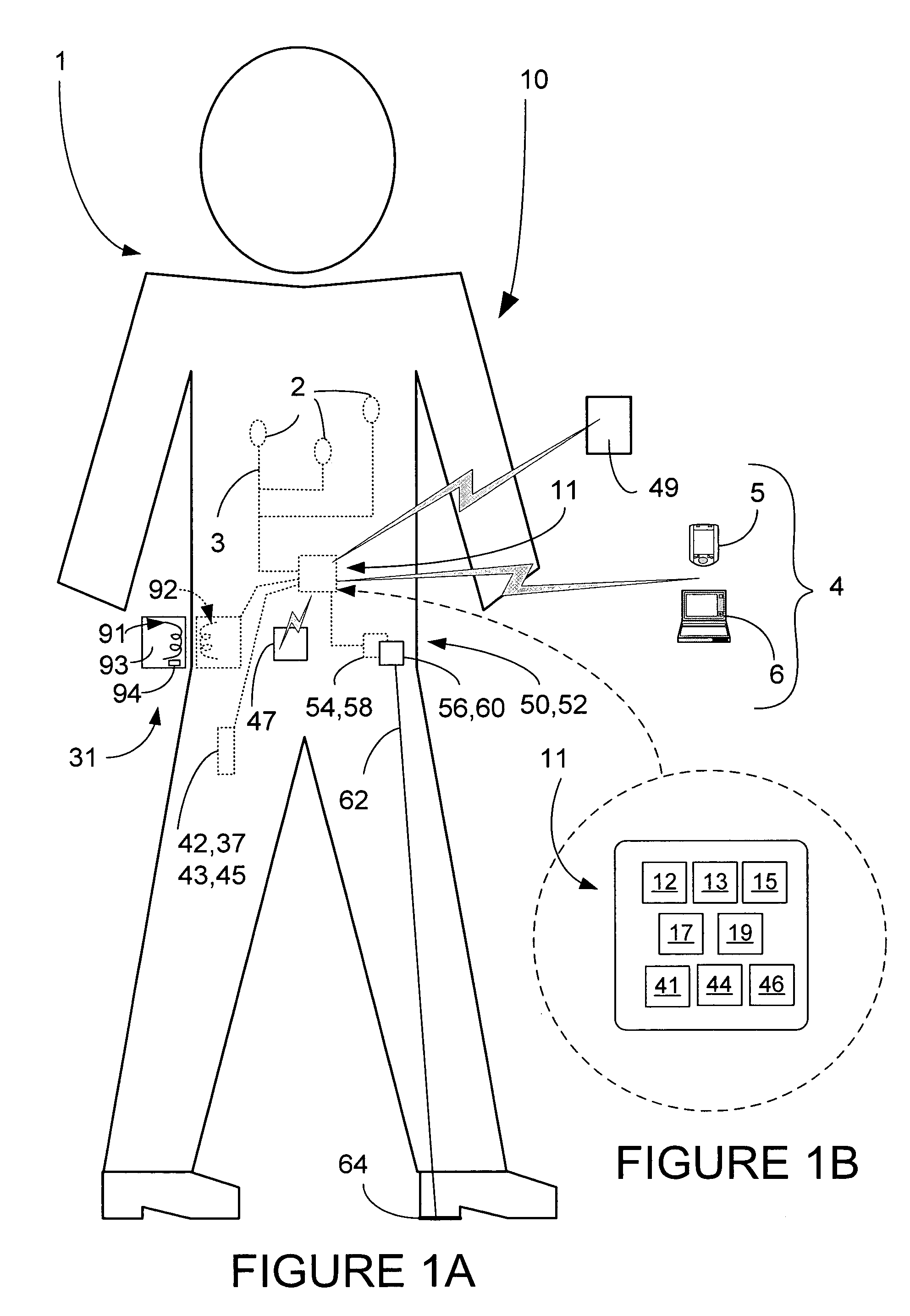

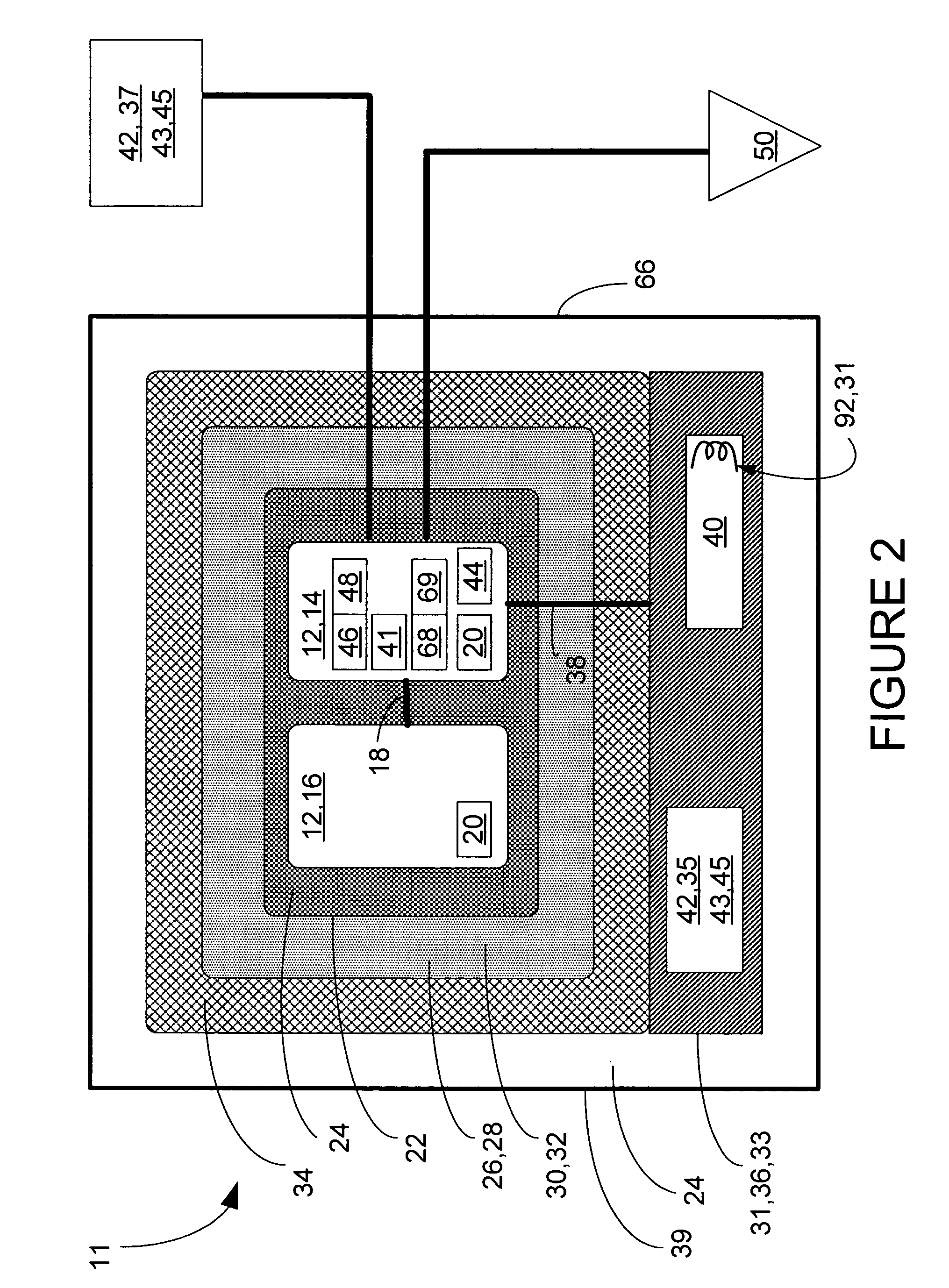

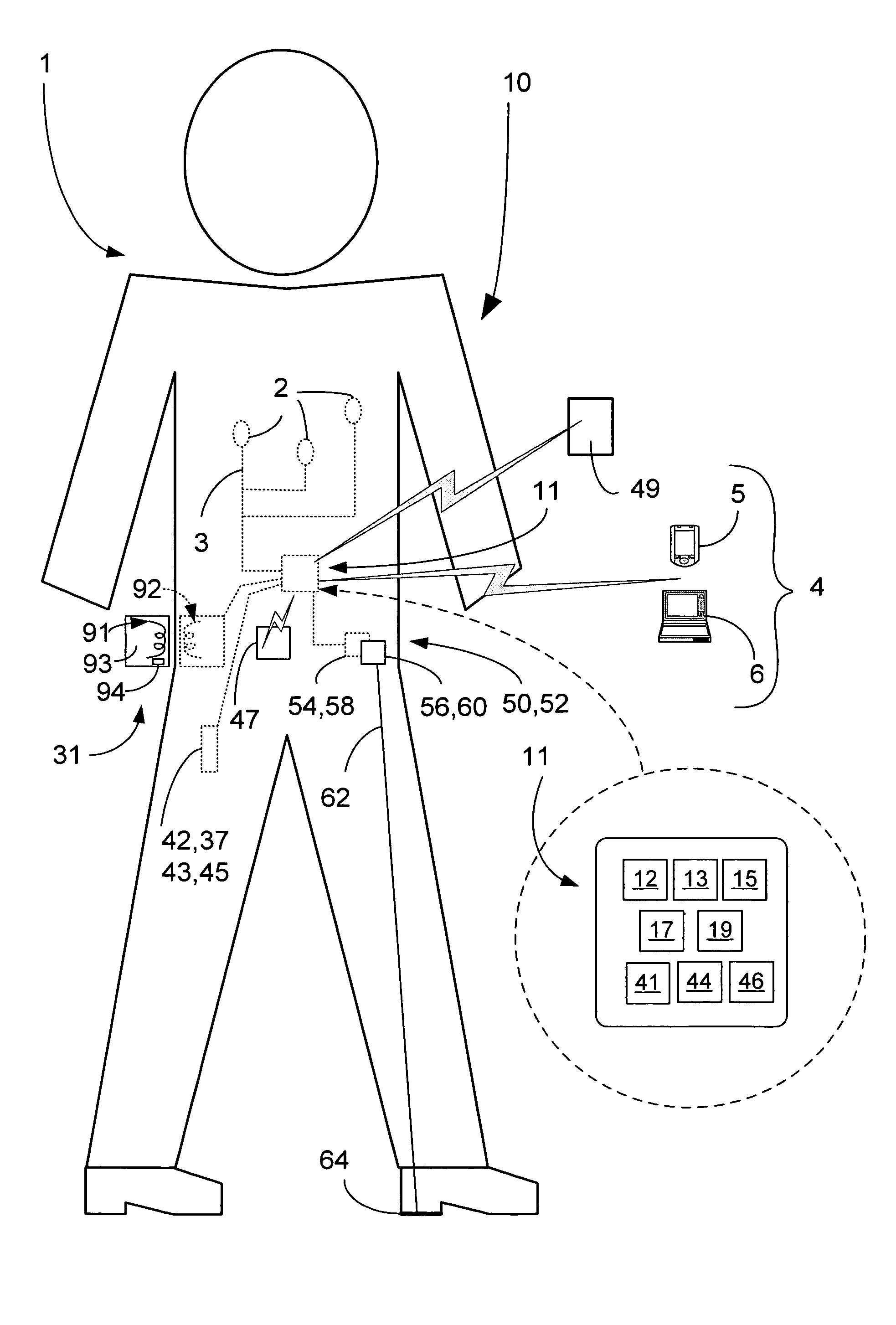

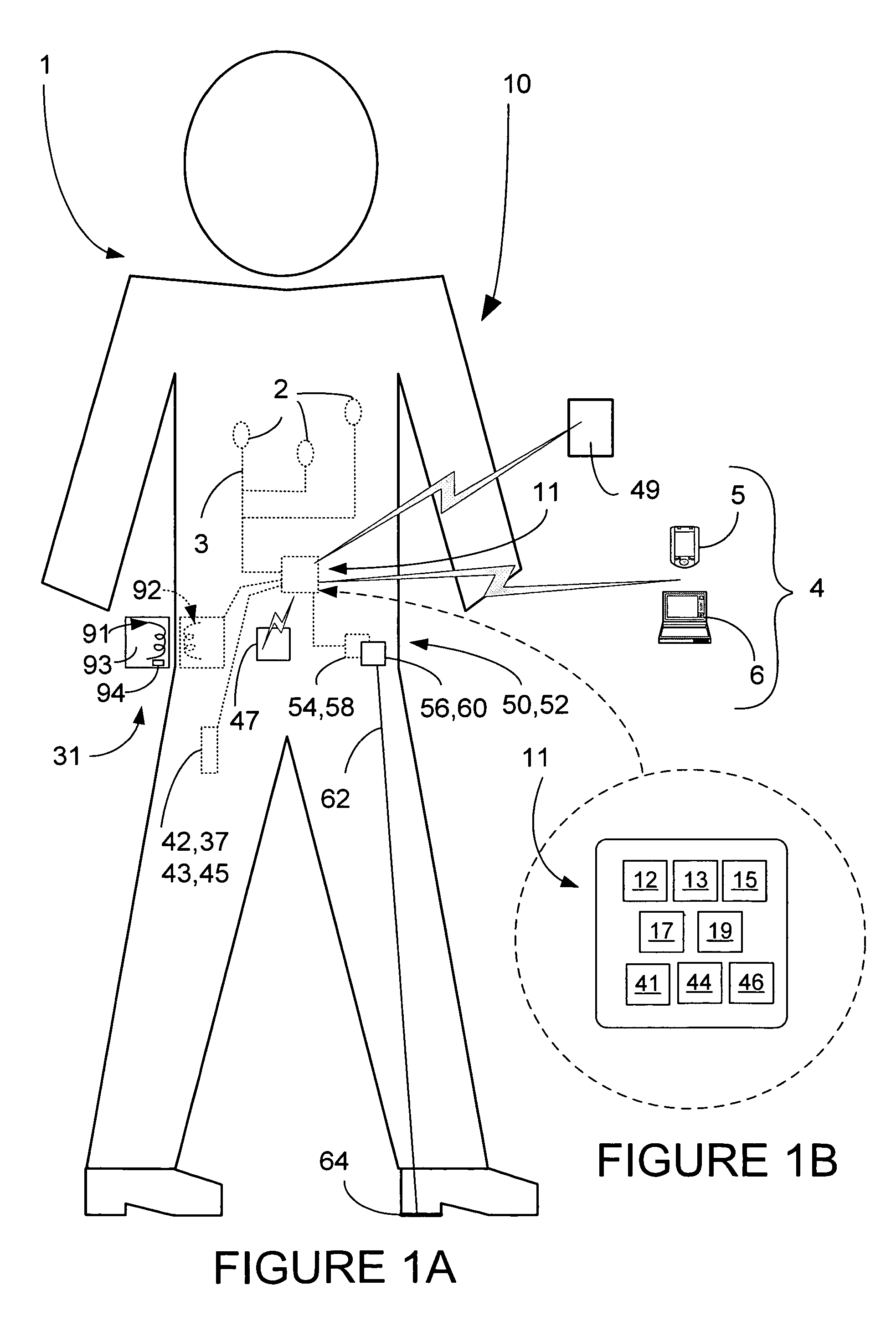

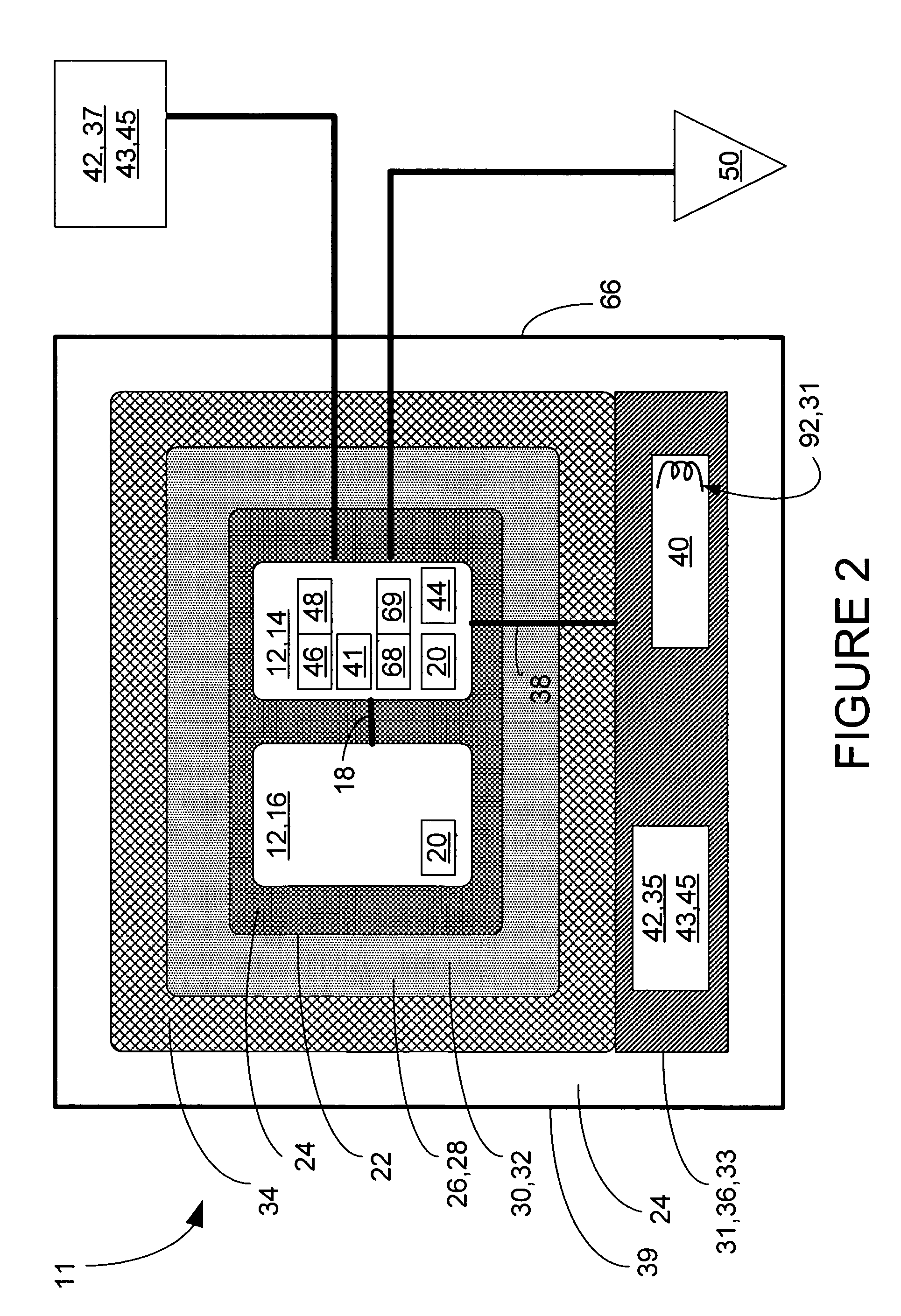

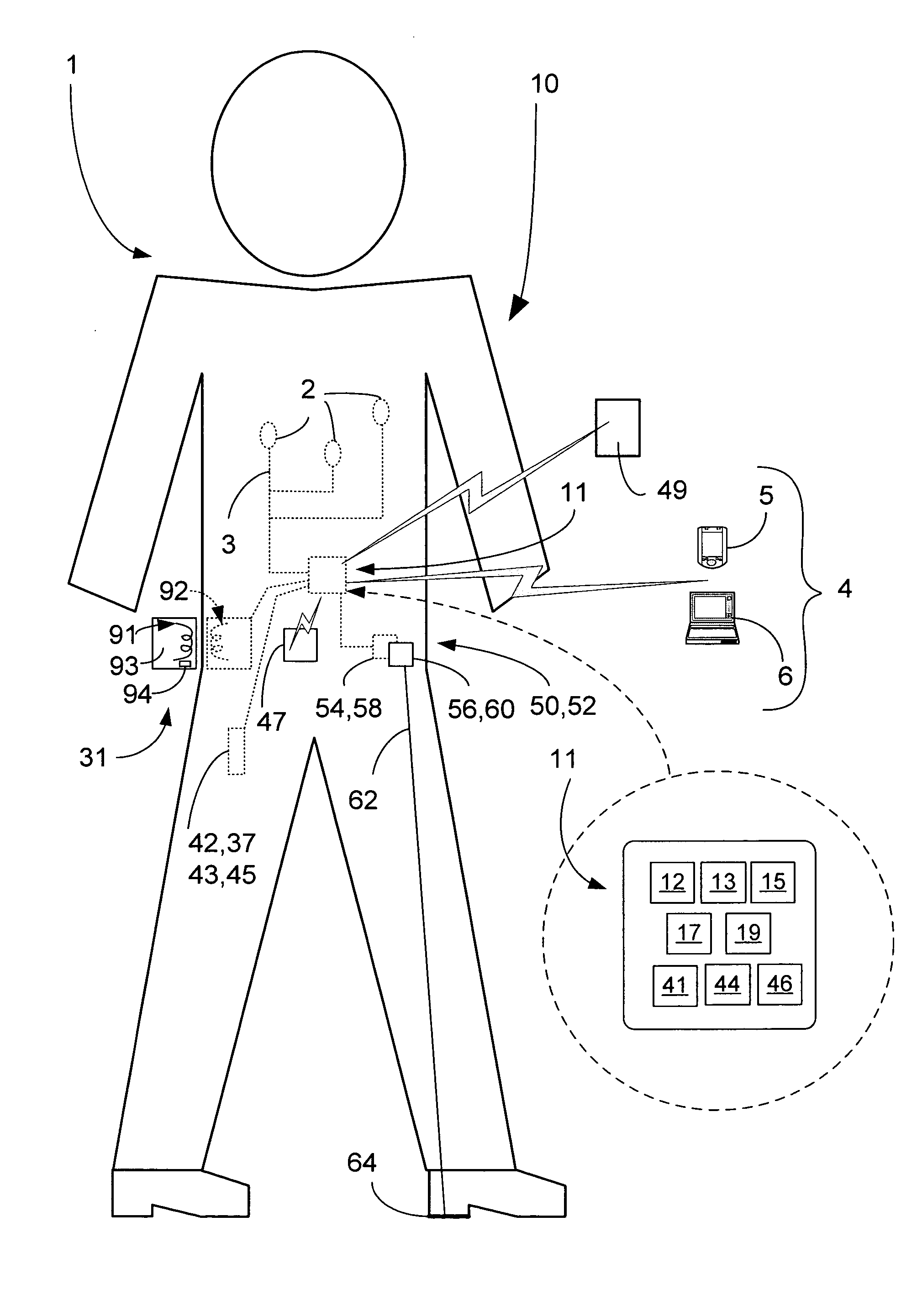

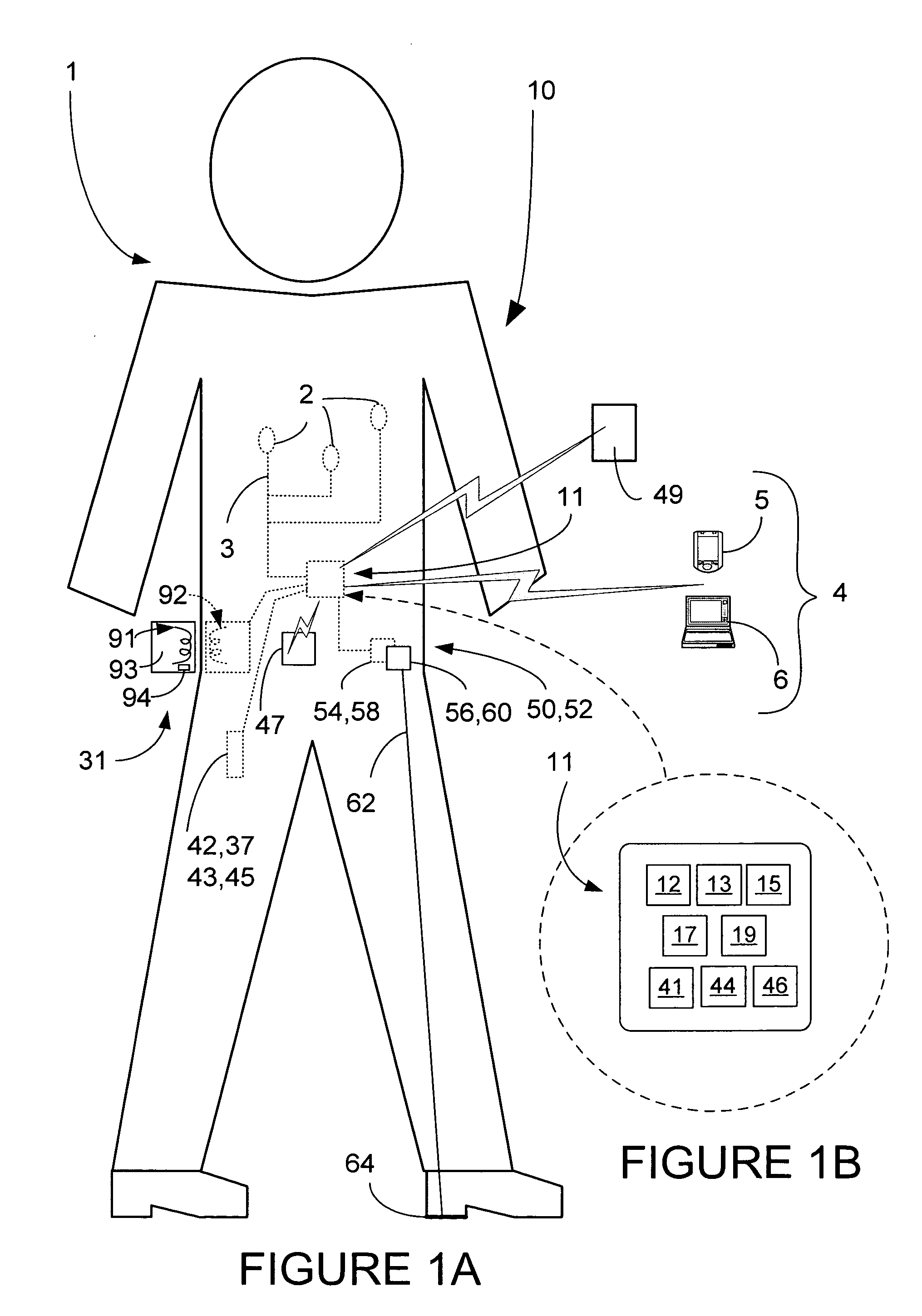

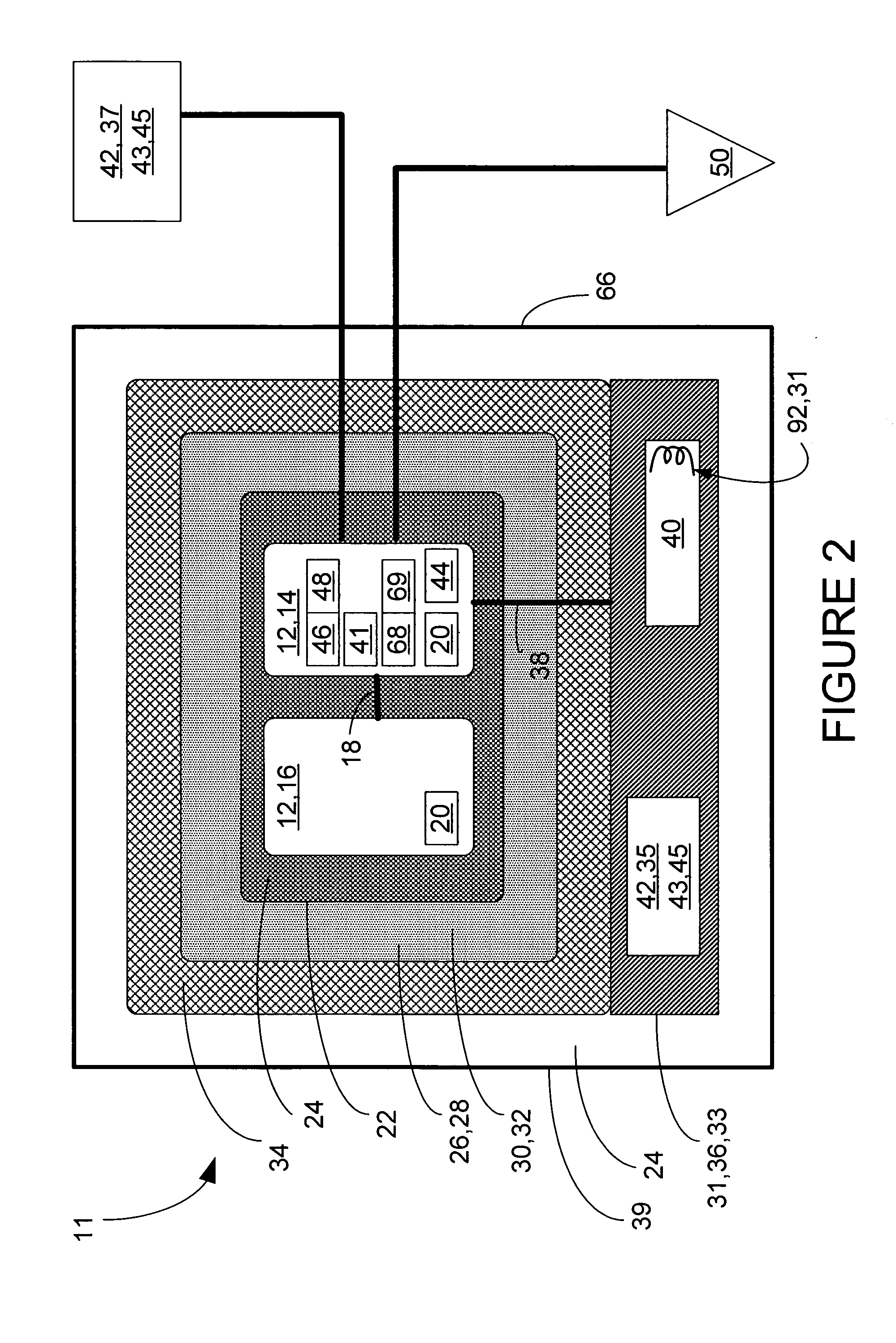

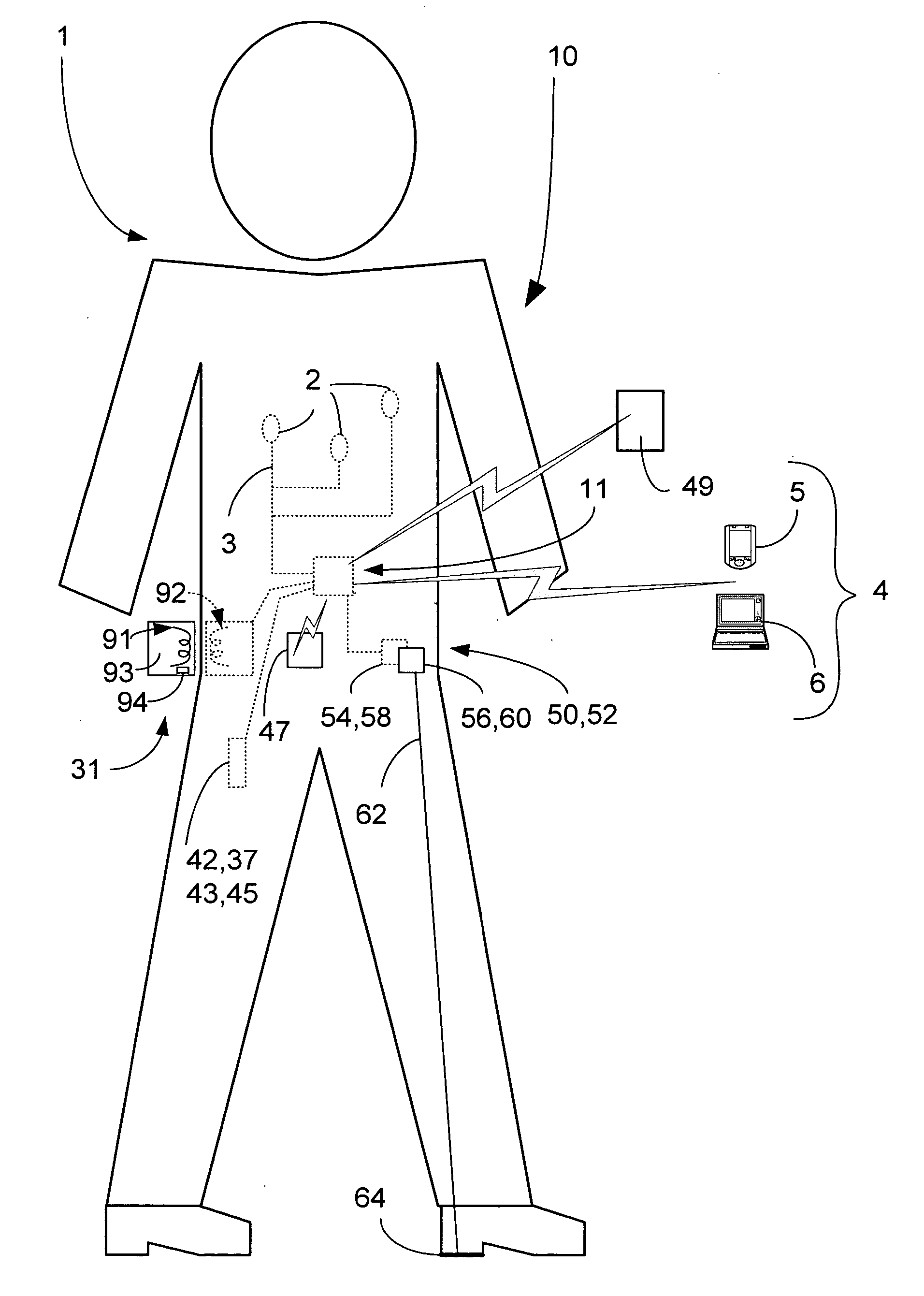

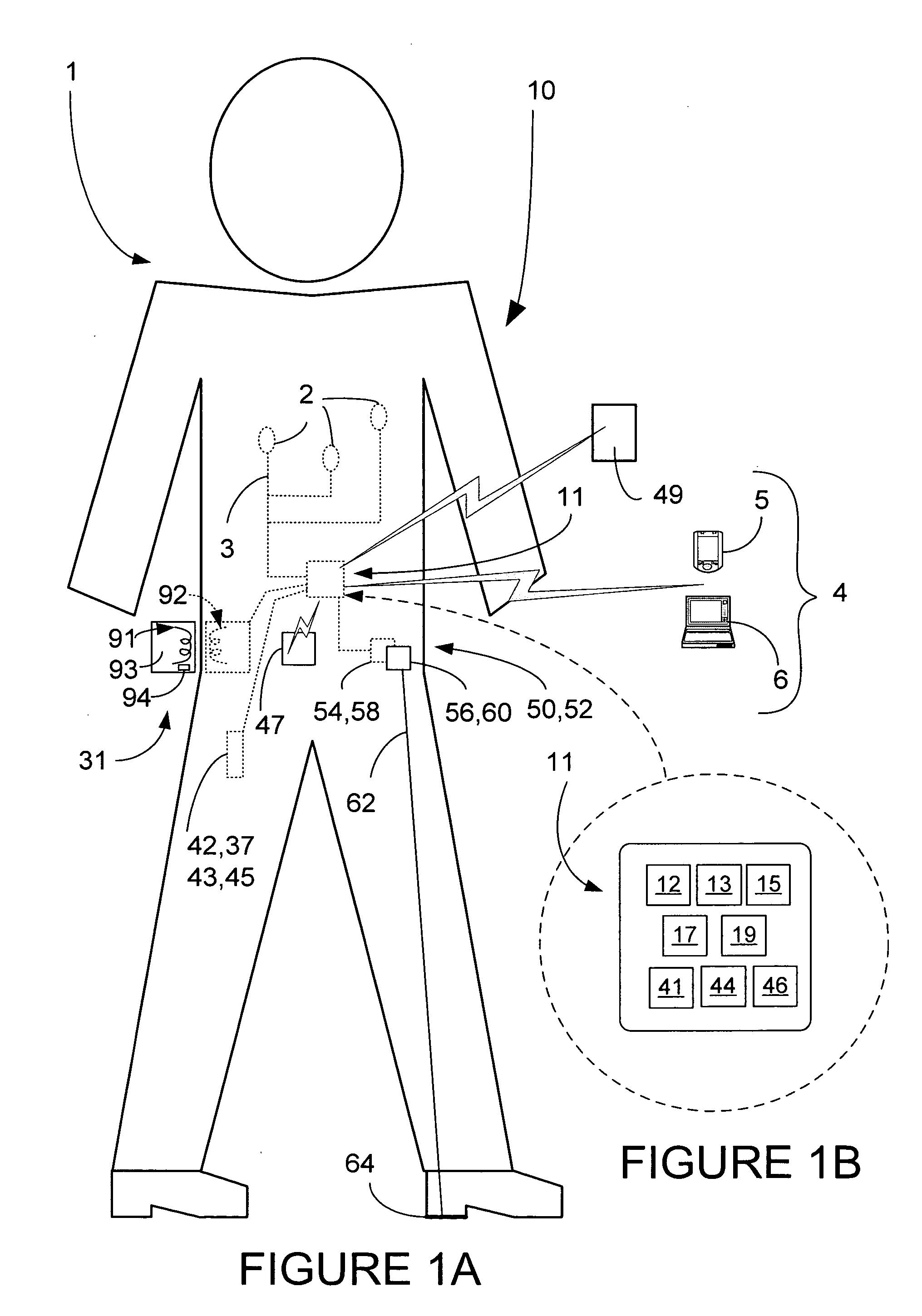

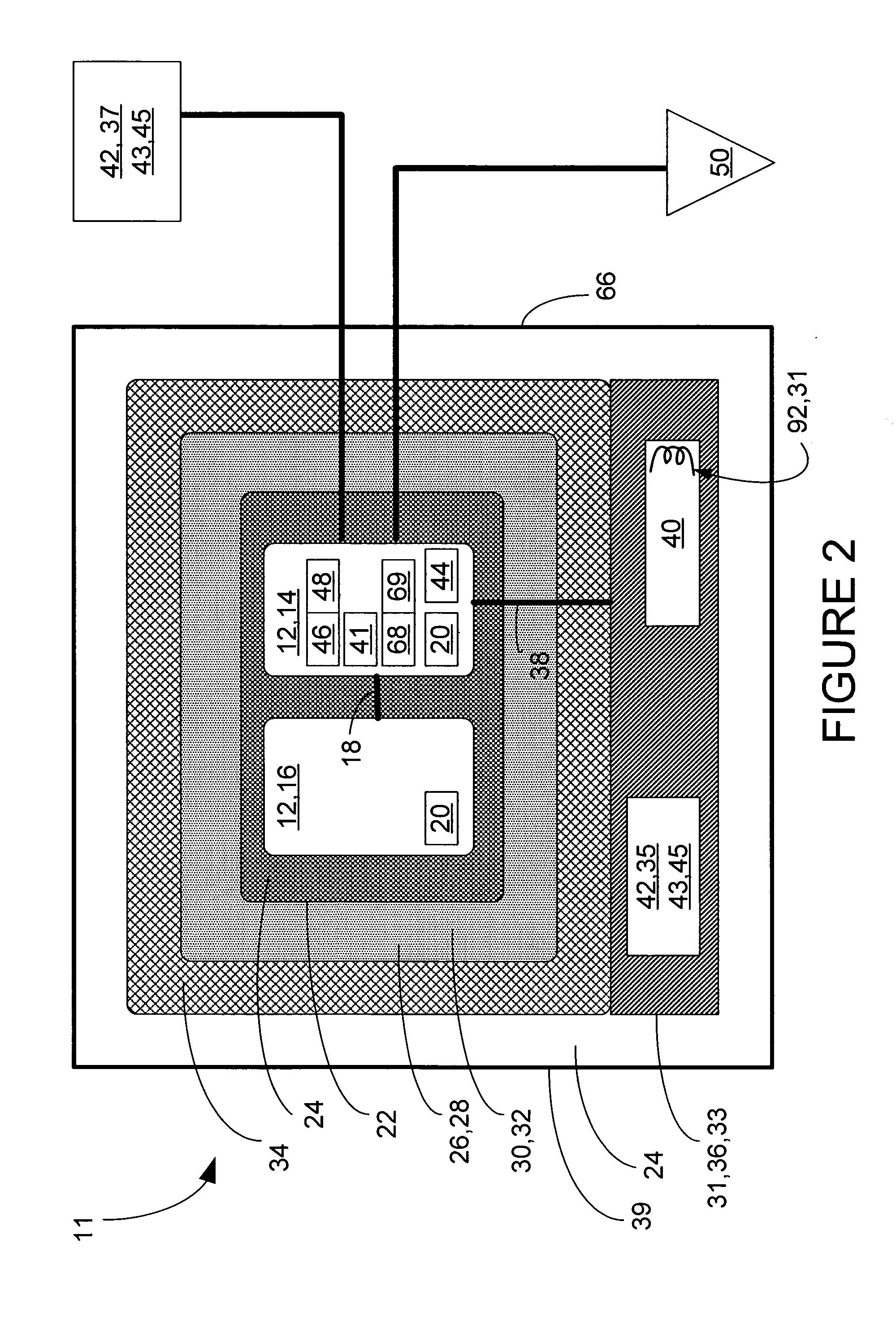

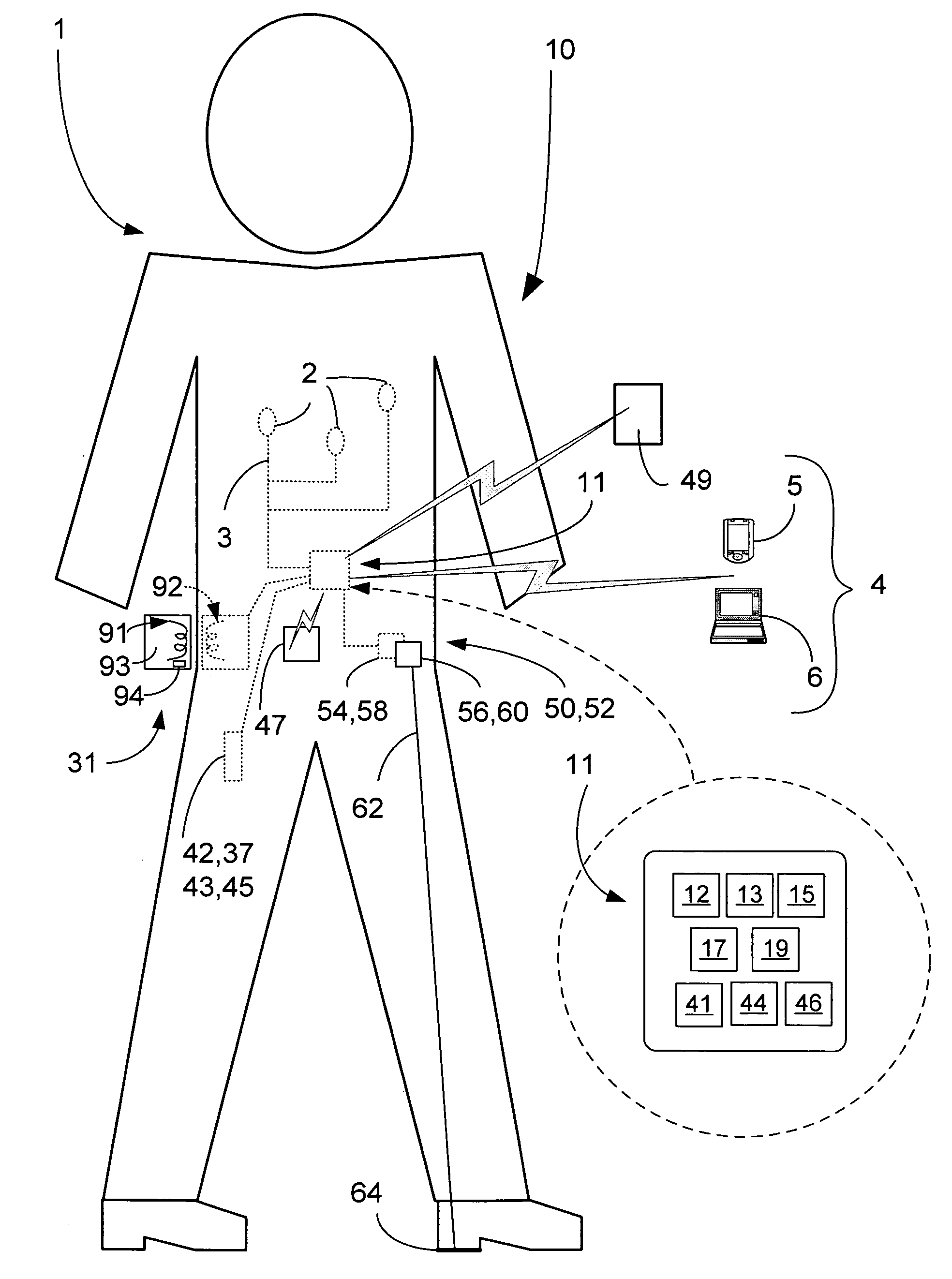

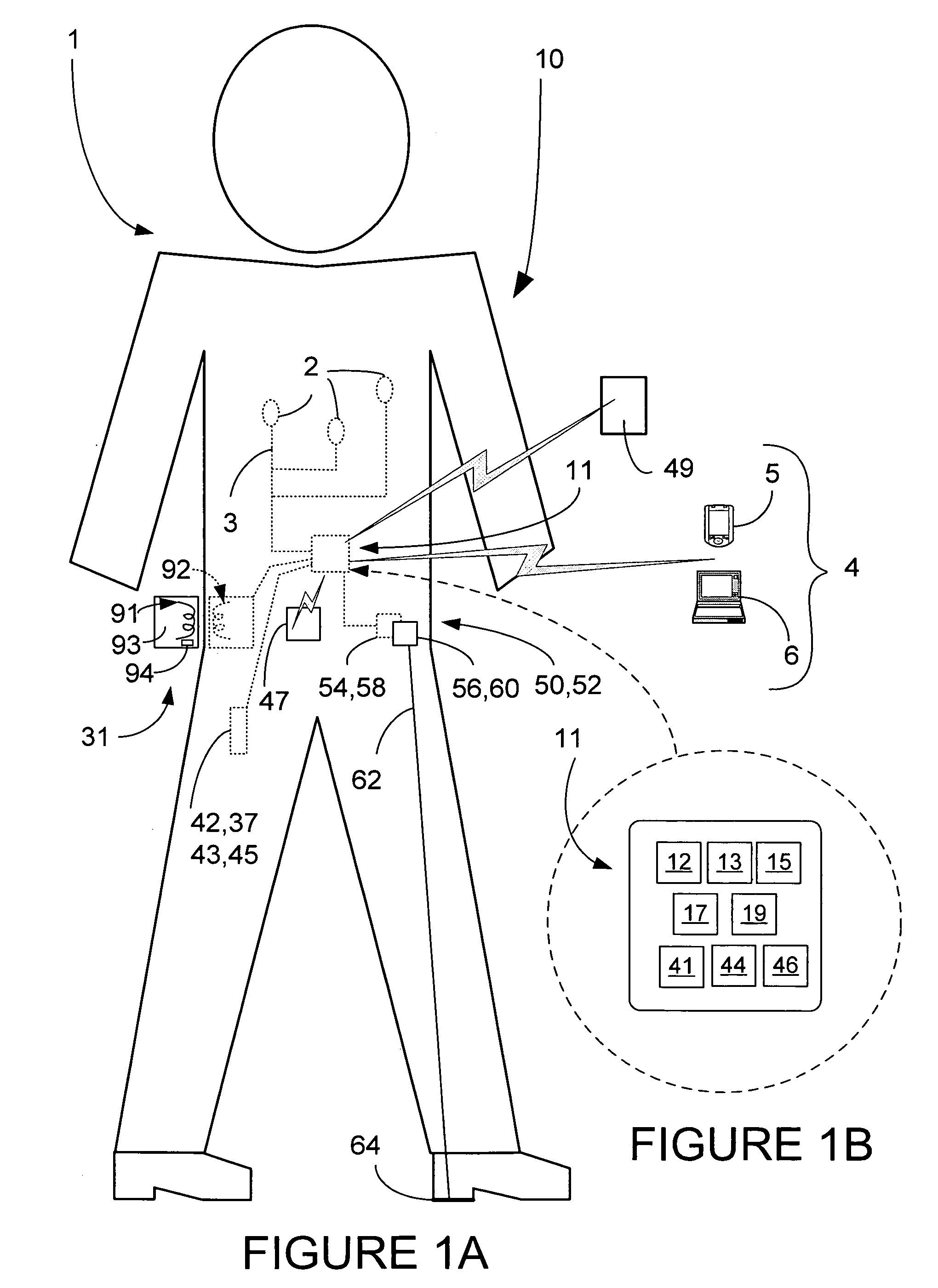

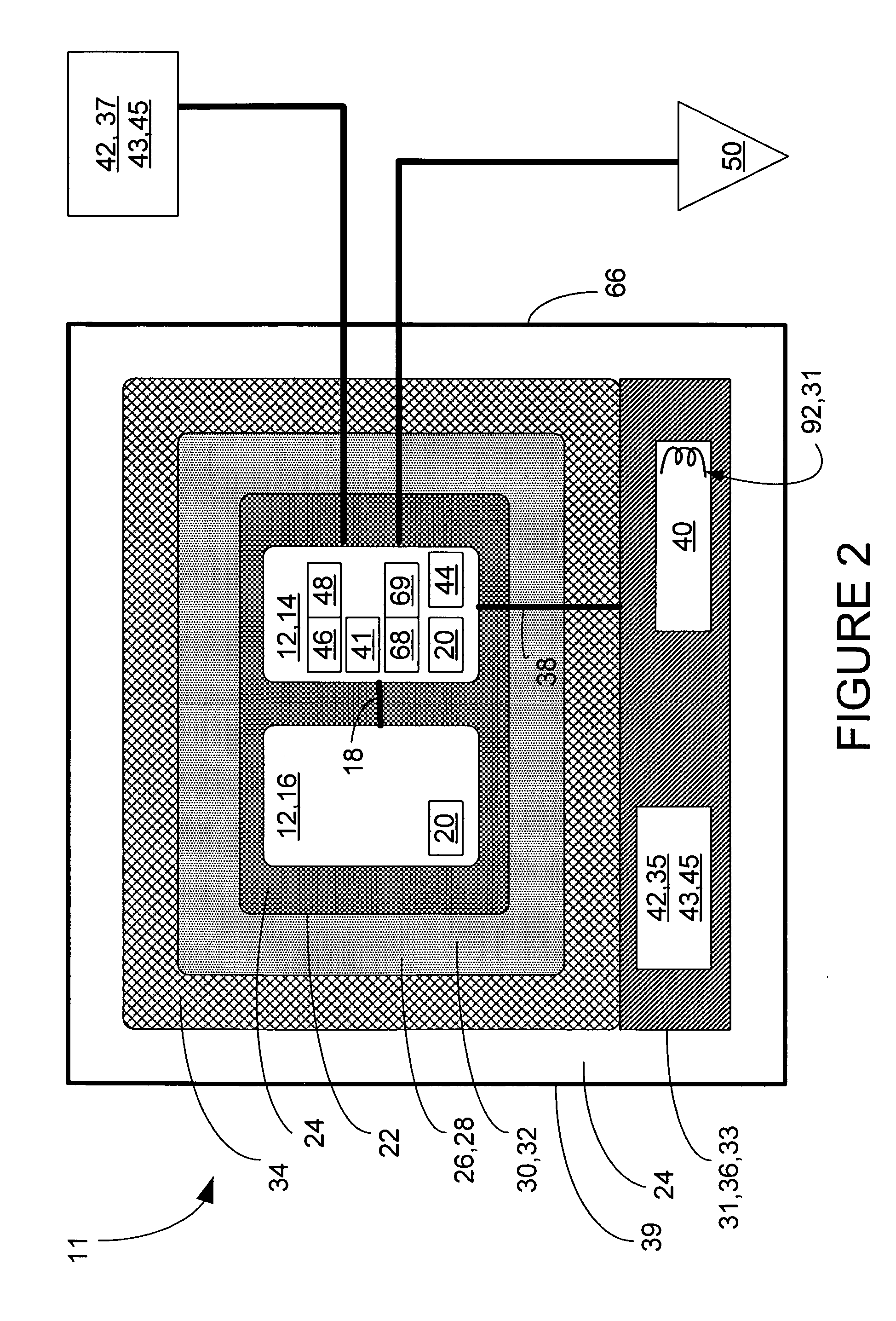

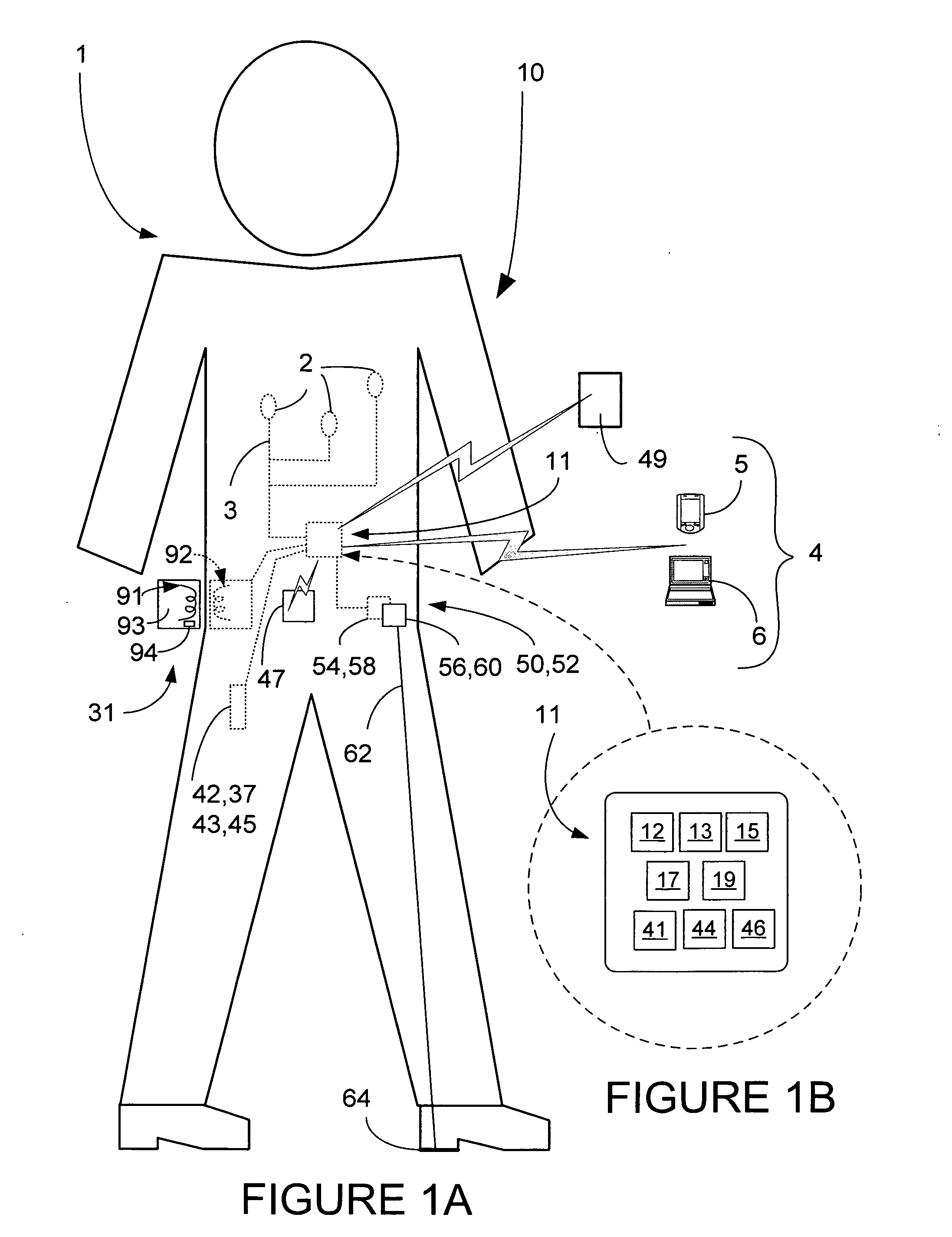

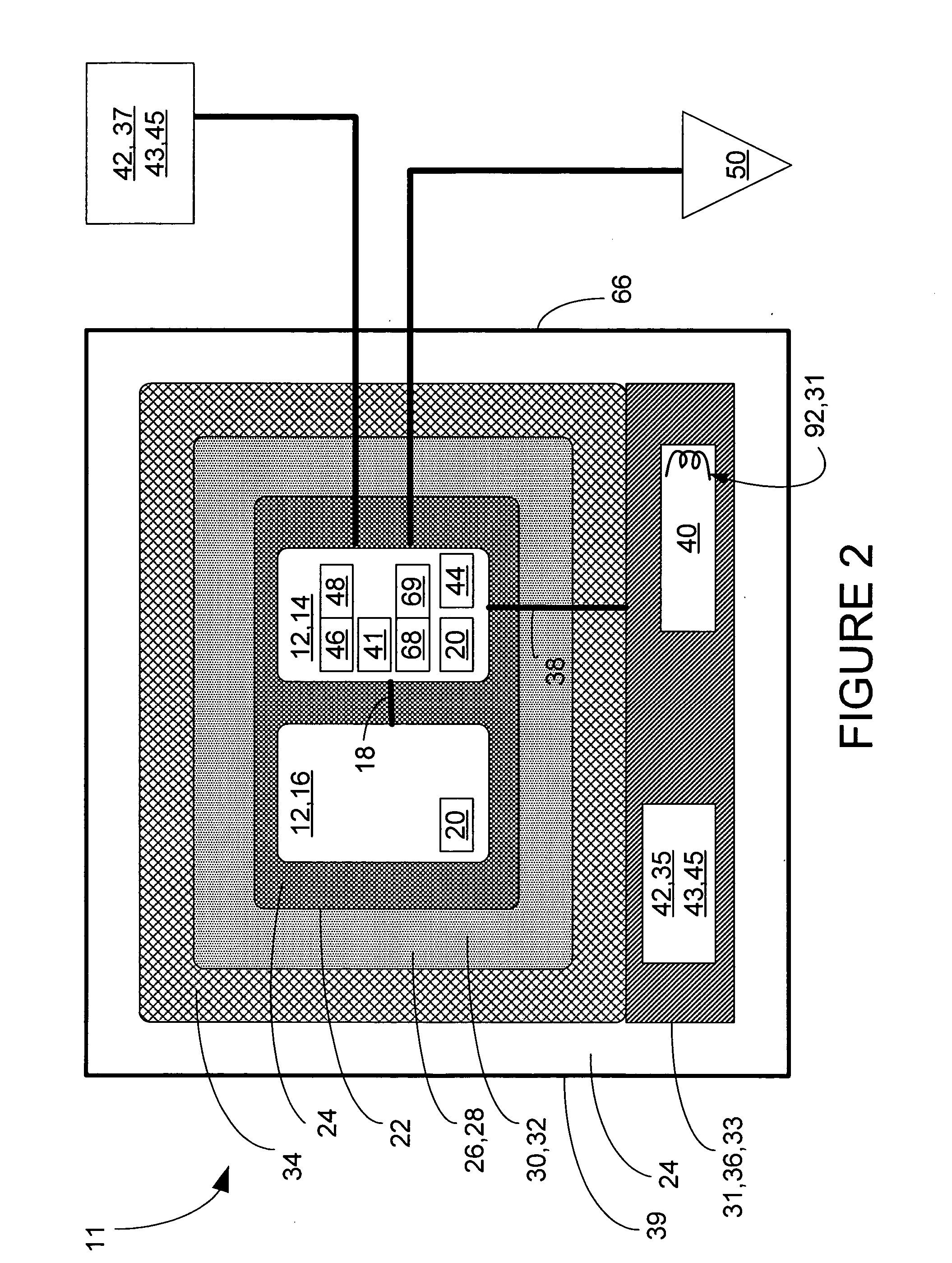

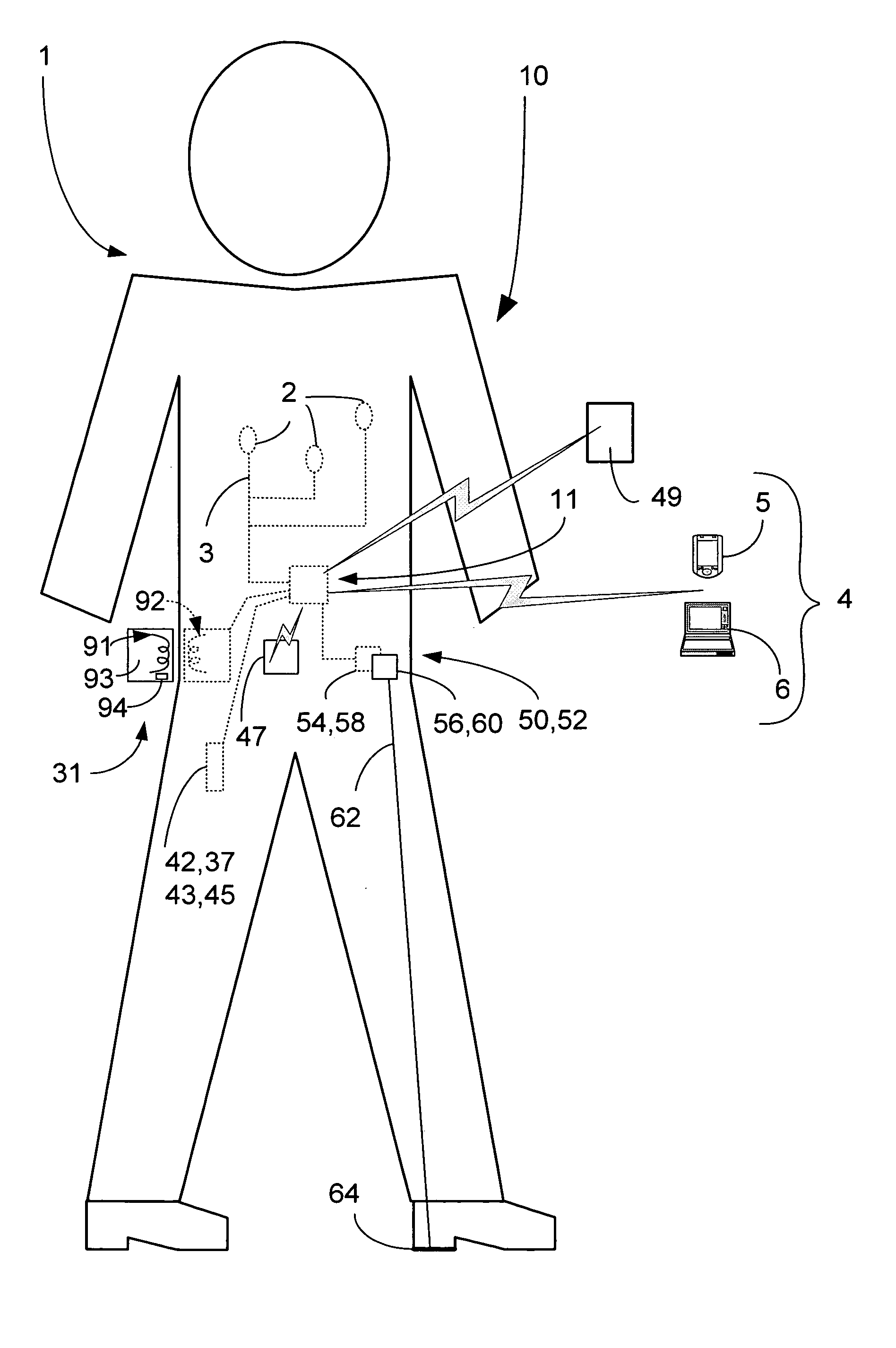

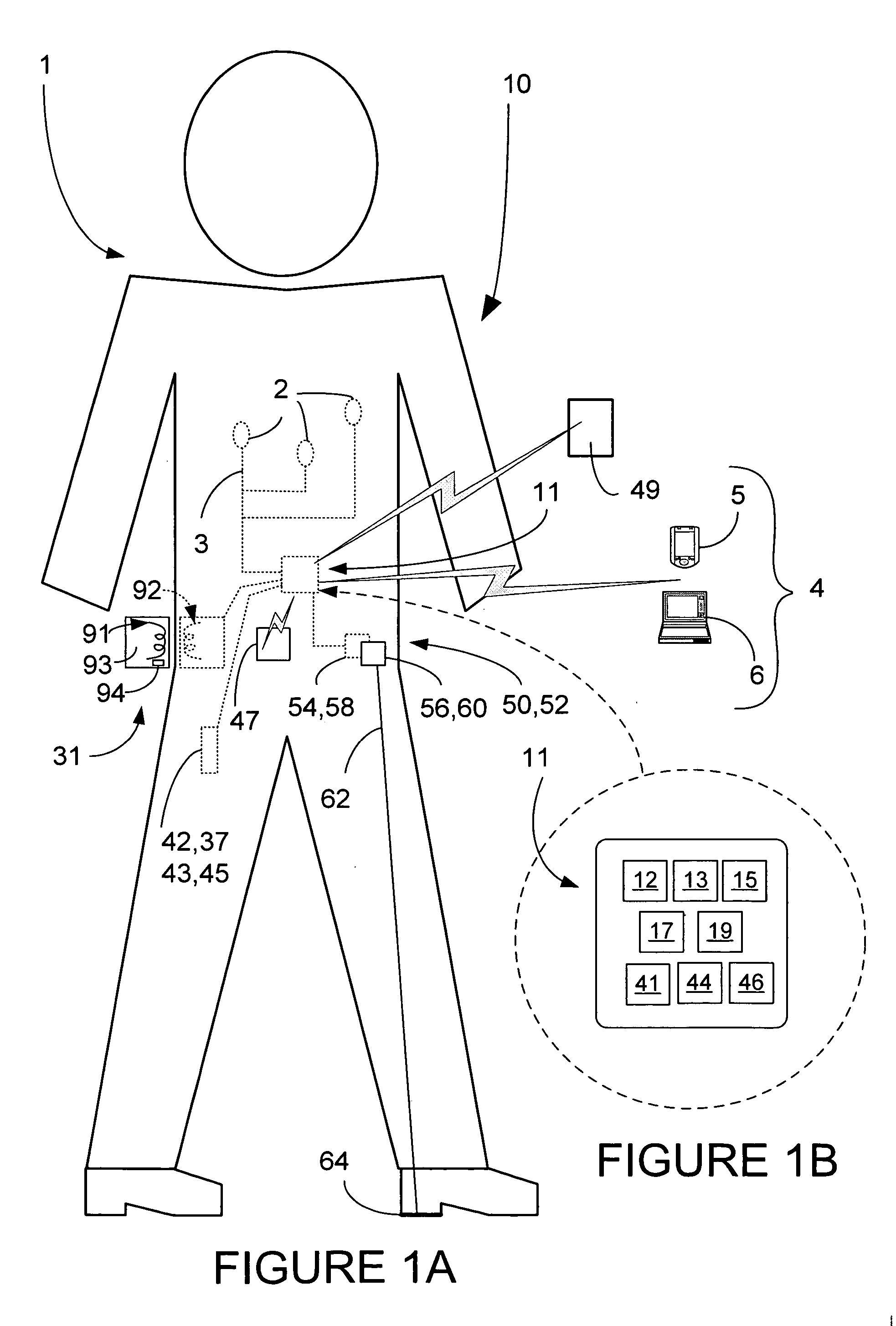

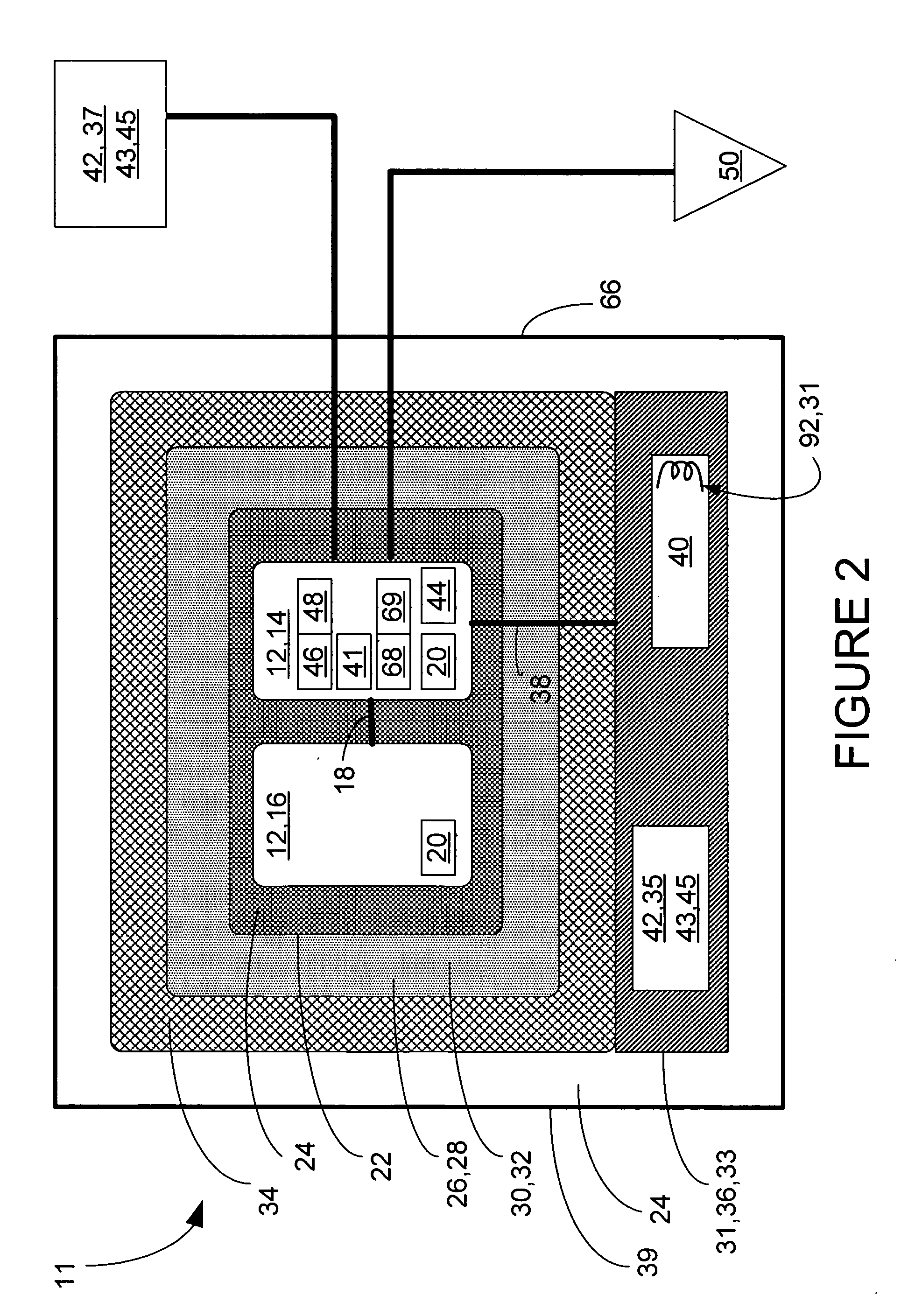

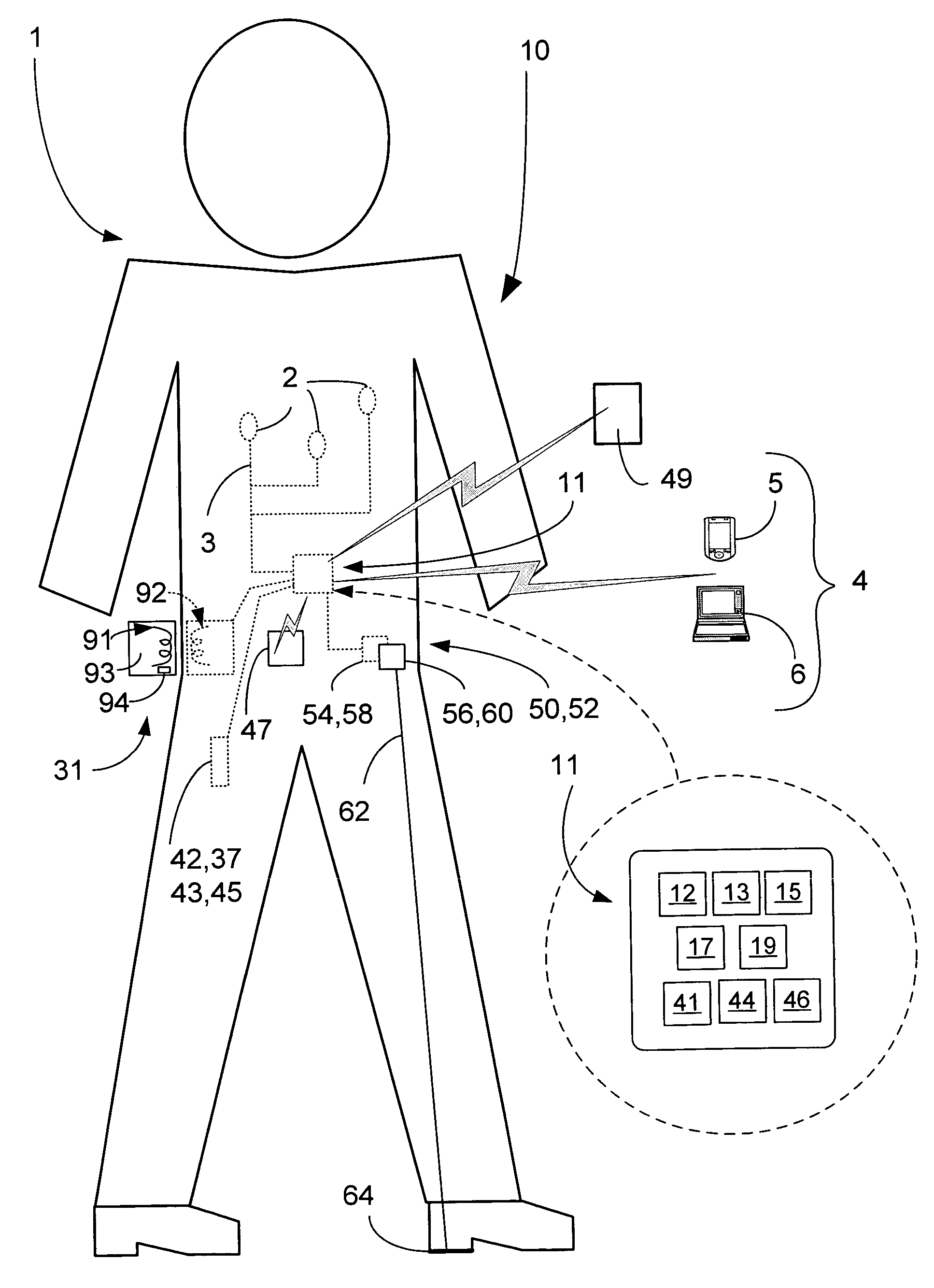

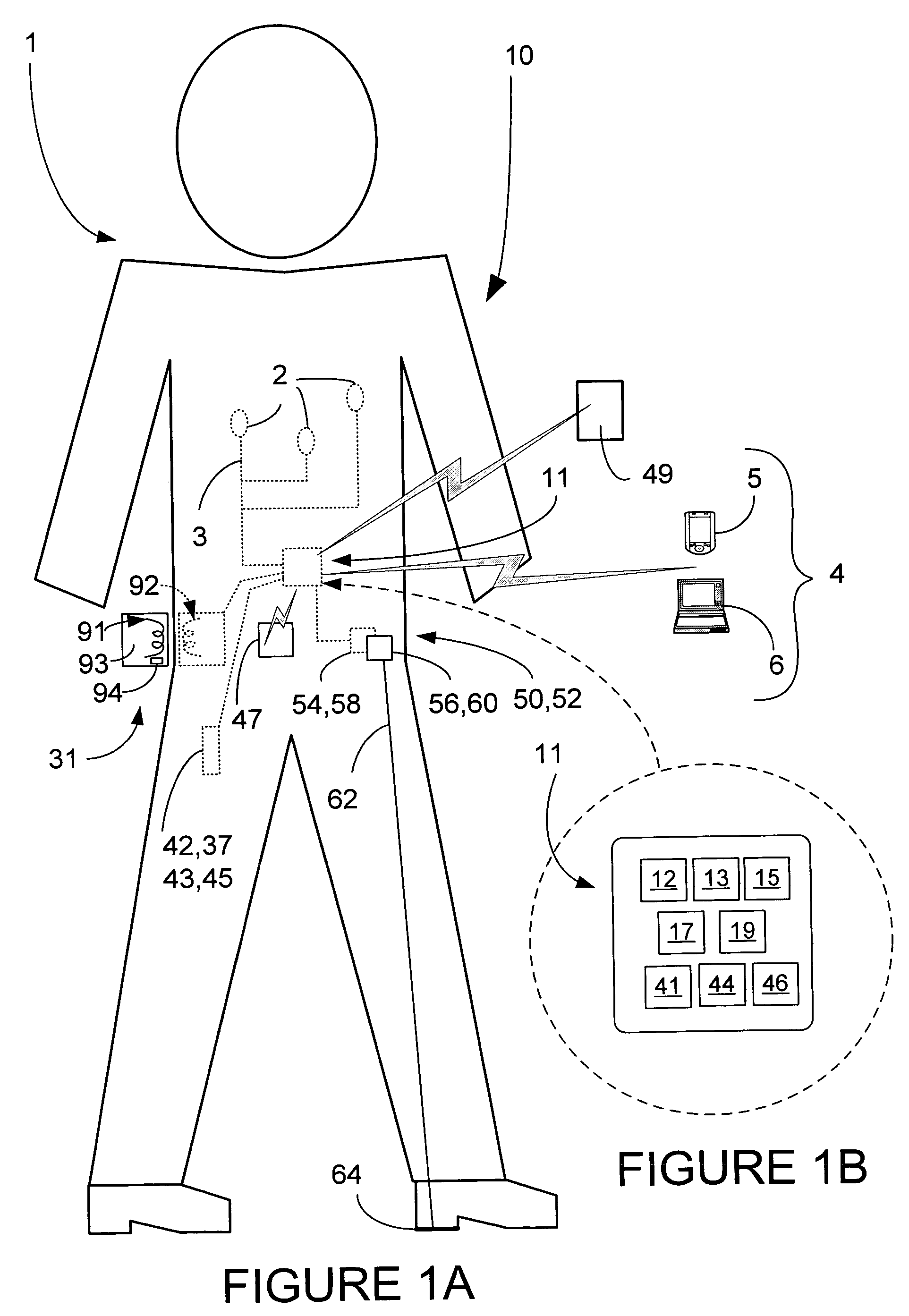

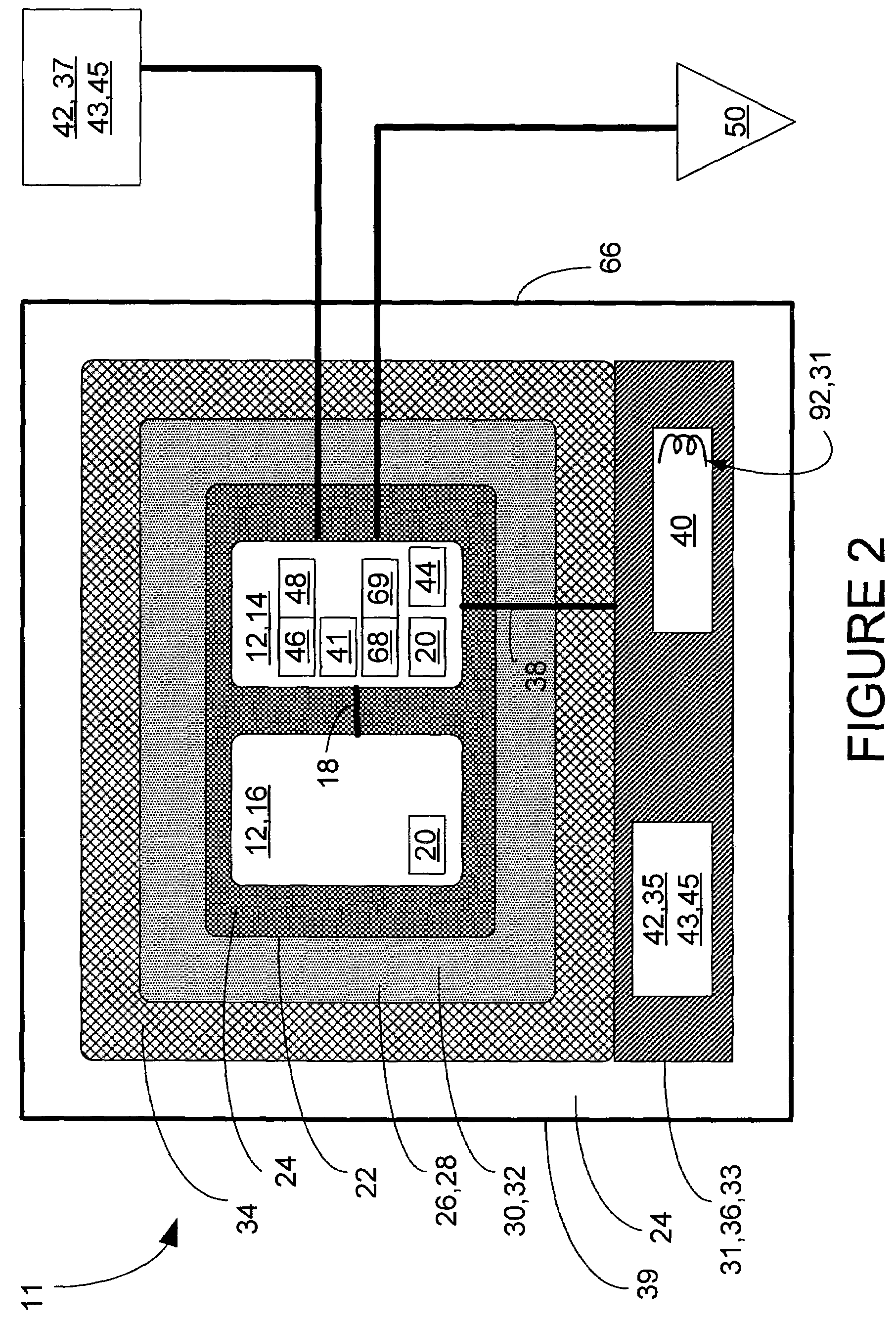

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. An enclosure surrounds the at least one hard disk drive. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one hard disk drive. A transmitter and receiver produces and transmits signals, and include a GPS transmitter and a receiver for producing and receiving transmission signals in the radio frequency range, where the GPS sends satellite communication signals via the public GPS frequencies and protocol.

Owner:WESTERN DIGITAL TECH INC

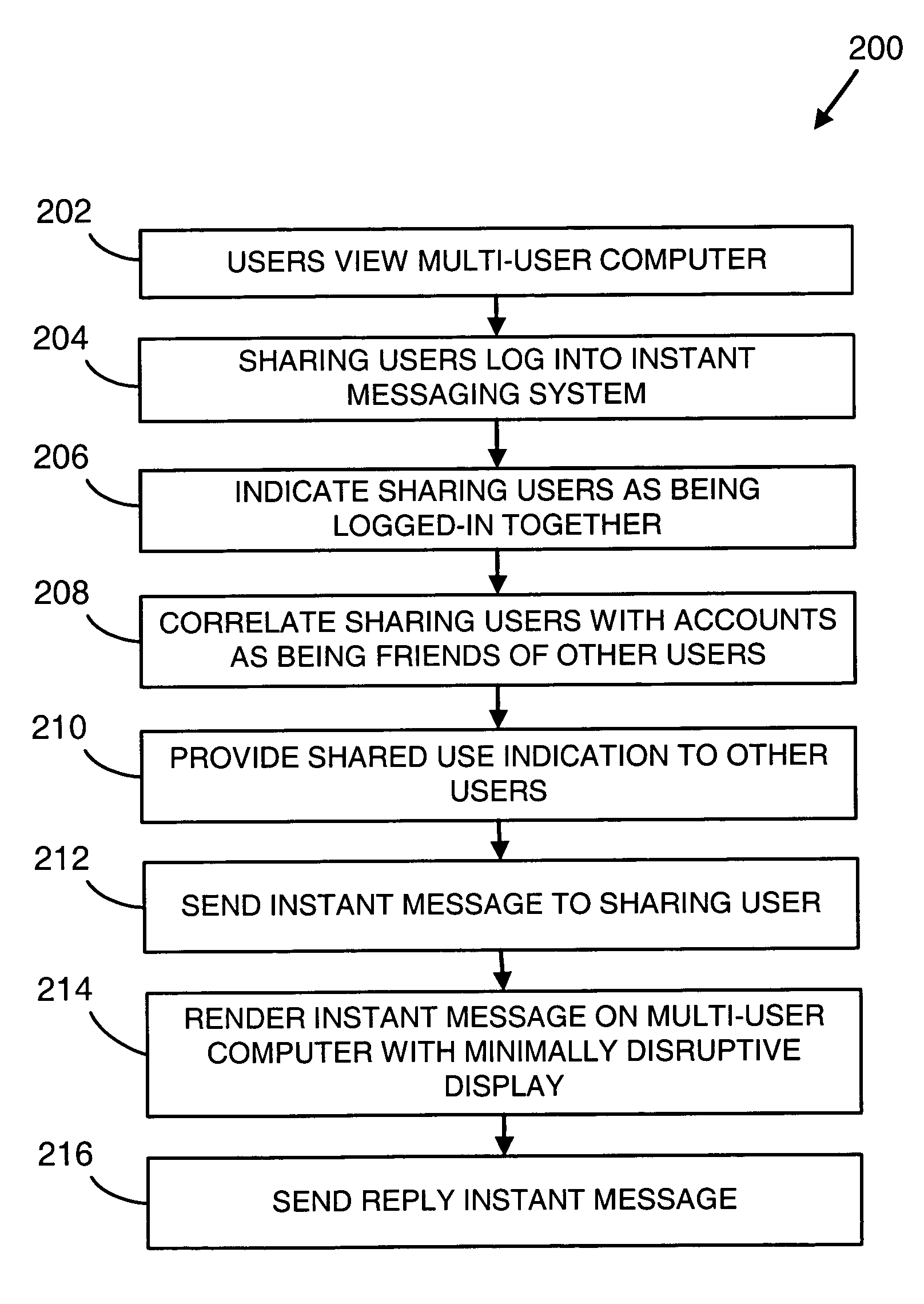

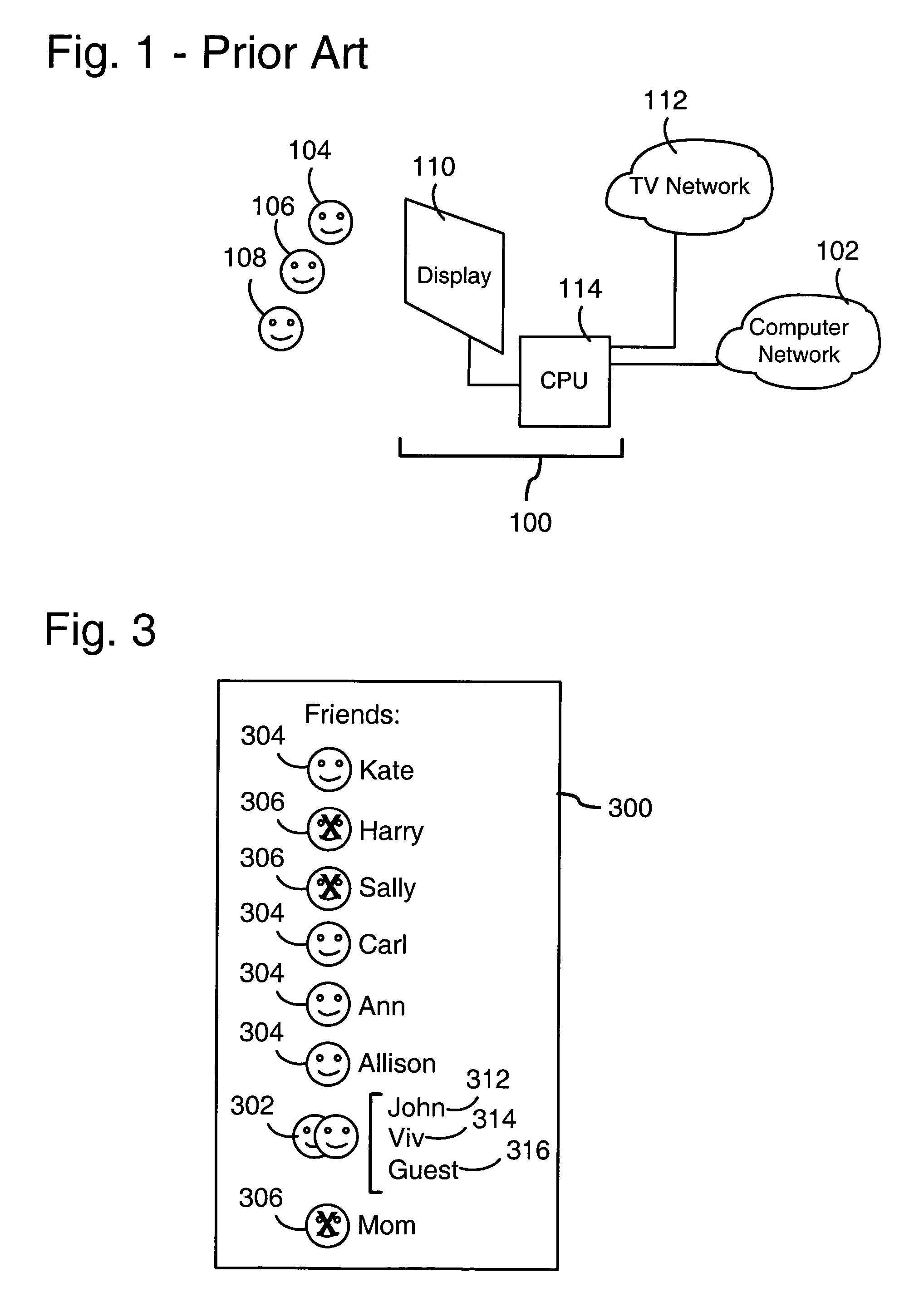

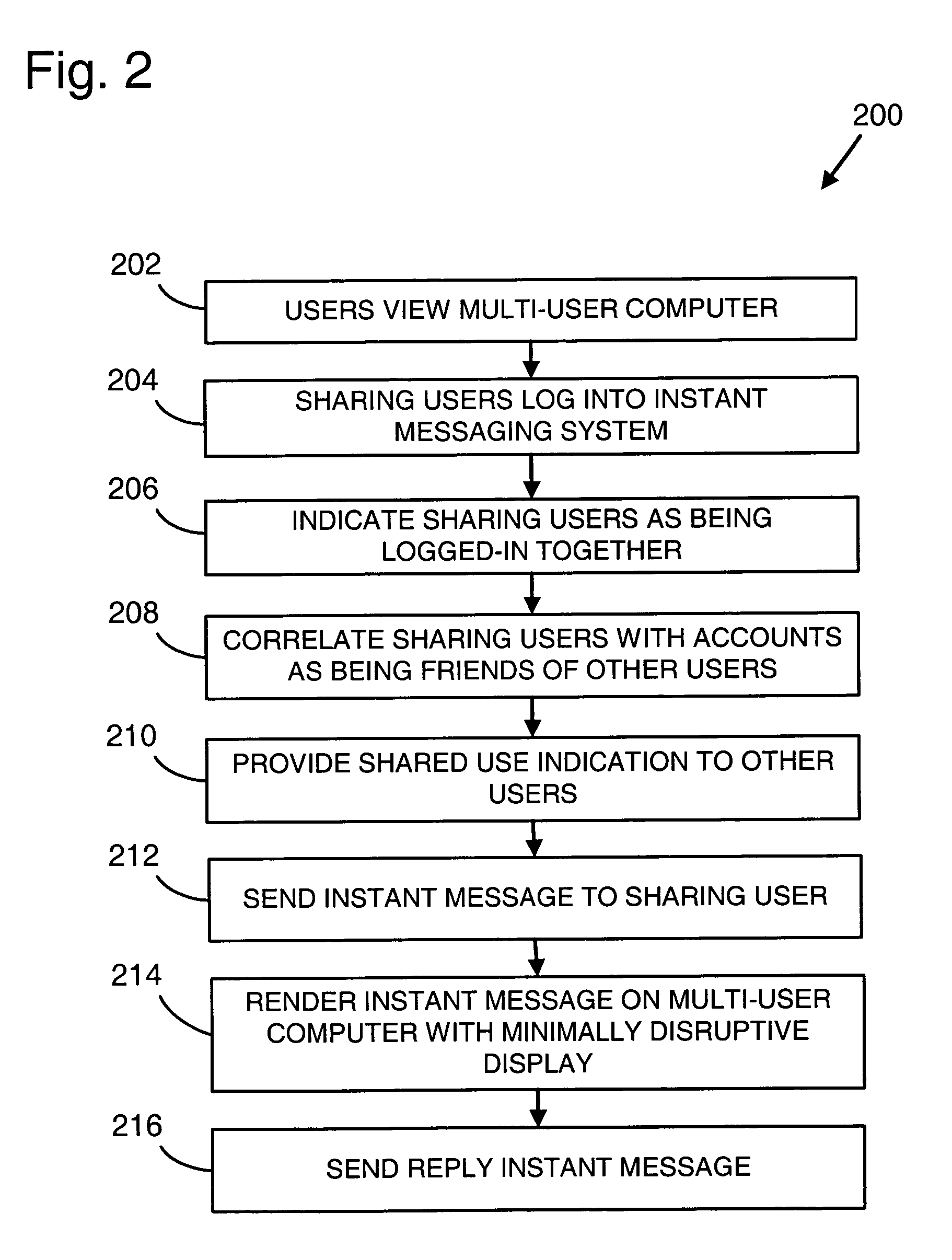

Instant messaging for multi-user computers

InactiveUS7640341B2Minimizing disruptivenessGuaranteed uptimeData processing applicationsMultiple digital computer combinationsInstant messagingMultimedia

An instant messaging system provides instant message communication between computers, including multi-user computers. The system provides multiple concurrent instant message user logins on a multi-user computer, one of the multiple concurrent instant message user logins being a registered buddy of a user of a second computer. The second computer is provided an indication that the registered buddy is one of multiple concurrent instant message user logins on a multi-user computer. The user of the second computer can send a message appropriate to be viewed on the multi-user computer. A video display may be rendered concurrently with the multiple concurrent instant message user logins. Instant messages are rendered over a portion of the video display. As a result, the instant messaging can operate smoothly with multi-user computers, protecting the privacy of instant messaging while minimizing the disruptiveness of instant messaging to accommodate shared use of a multi-user computer.

Owner:MICROSOFT TECH LICENSING LLC

Hard disk drive medical monitor with sound-proofing

InactiveUS20060004263A1Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveComputer science

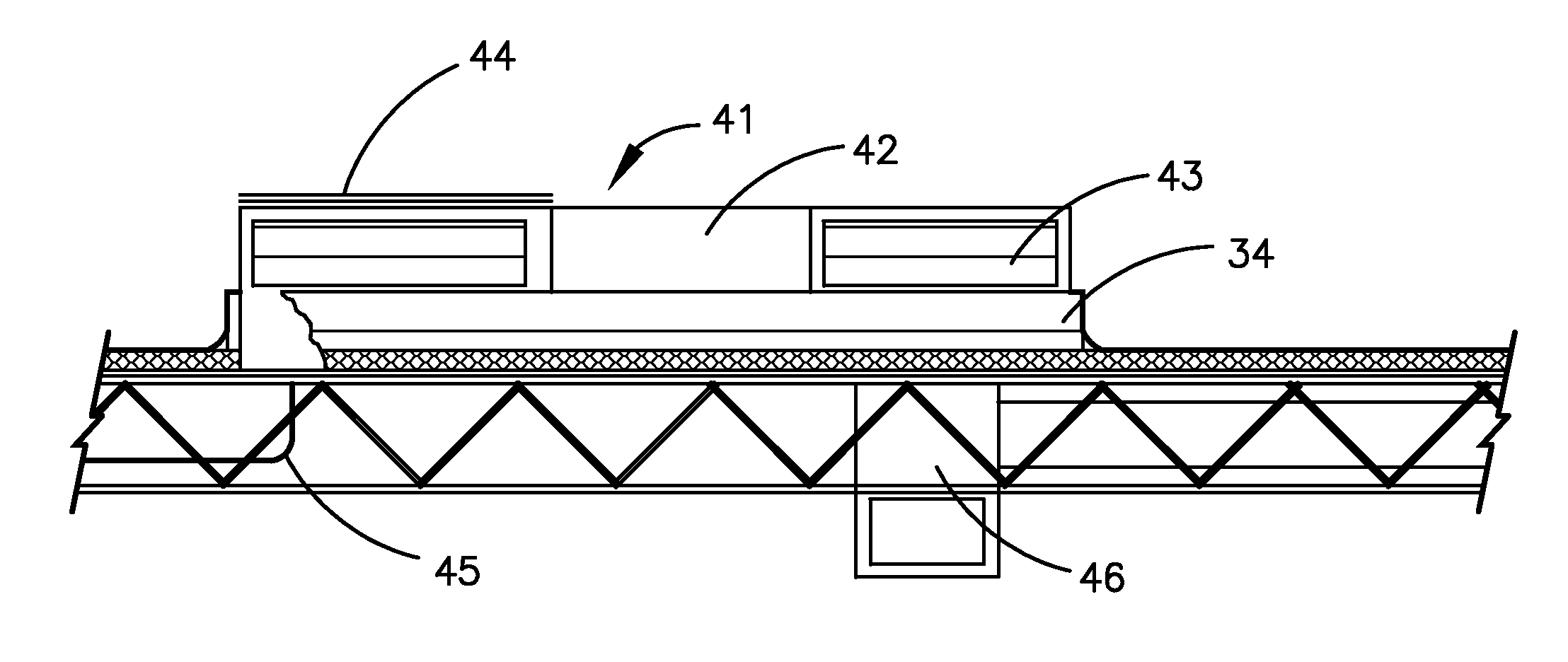

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver for produces and transmits signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive, where the enclosure includes sound-proofing materials.

Owner:WESTERN DIGITAL TECH INC

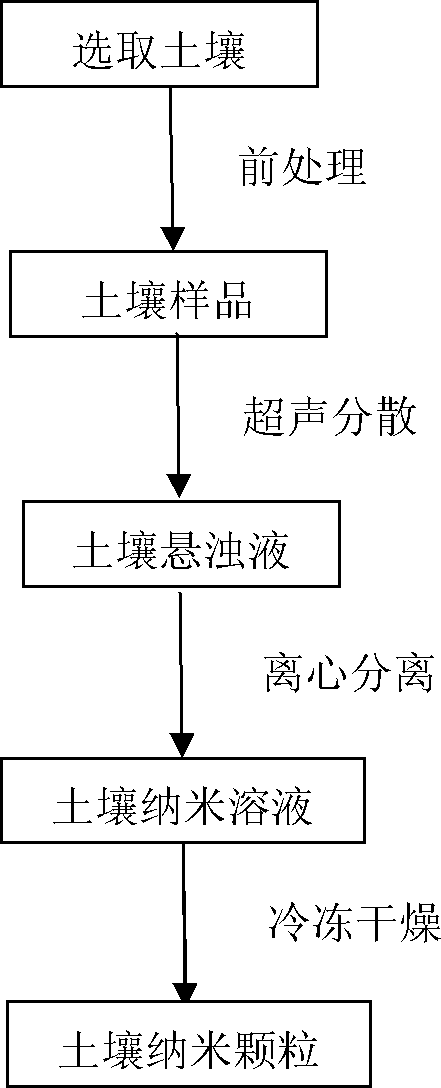

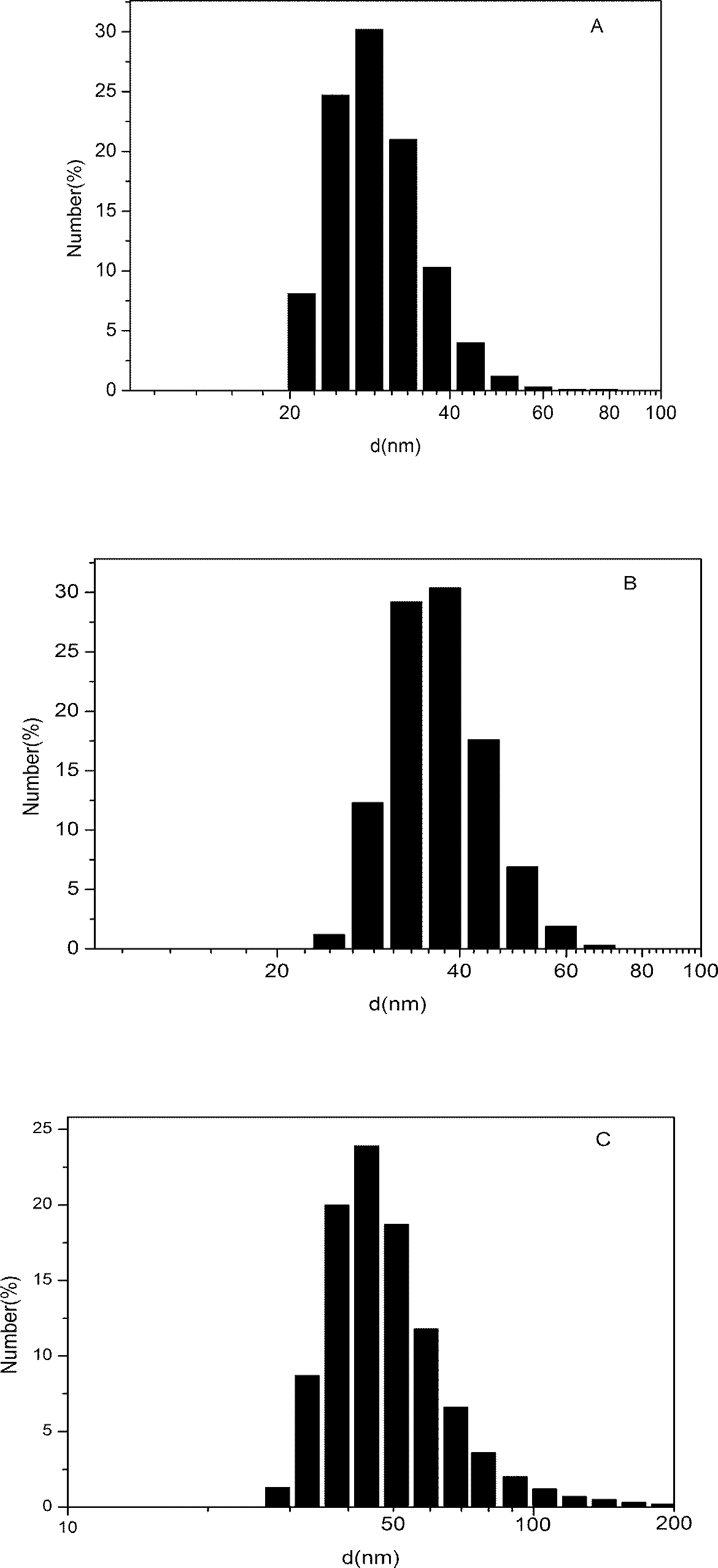

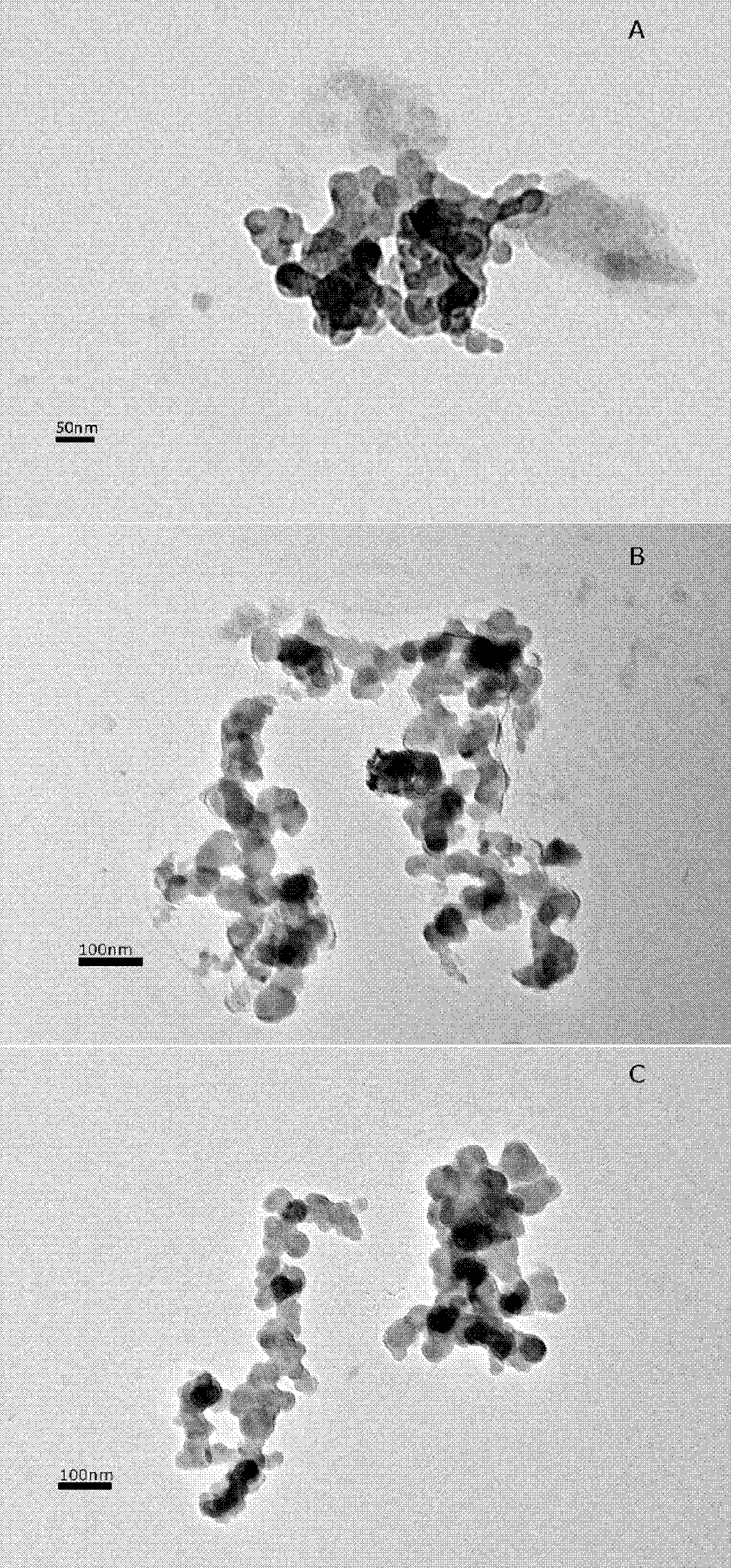

Method for extracting soil nanoscale particles

InactiveCN102319546AAvoid the risk of introducingFully dispersedShaking/oscillating/vibrating mixersDrying solid materials without heatSoil scienceBrick

The invention discloses a method for extracting soil nanoscale particles. The method comprises the steps of: (1) selecting black soil, brown soil or latosol as suitable soil; (2) crushing and sieving the naturally aired suitable soil, adding distilled water in the sieved soil and performing uniform ultrasonic dispersion for the obtained soil turbid liquid; and (3) sieving the ultrasonically dispersed soil turbid liquid, placing the sieved soil turbid liquid in a centrifuge tube to be centrifuged under the condition with the centrifugal force of 900-1100 g for 22-25 min so as to obtain an upper suspension as a soil nanoscale particle solution. According to the invention, the method for extracting the soil nanoscale particles from the soil is clean, rapid and free from use of chemical dispersants.

Owner:ZHEJIANG UNIV

Hard disk drive medical monitor with GPS

InactiveUS7192398B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveDisplay device

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. An enclosure surrounds the at least one hard disk drive. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one hard disk drive. A transmitter and receiver produces and transmits signals, and include a GPS transmitter and a receiver for producing and receiving transmission signals in the radio frequency range, where the GPS sends satellite communication signals via the public GPS frequencies and protocol.

Owner:WESTERN DIGITAL TECH INC

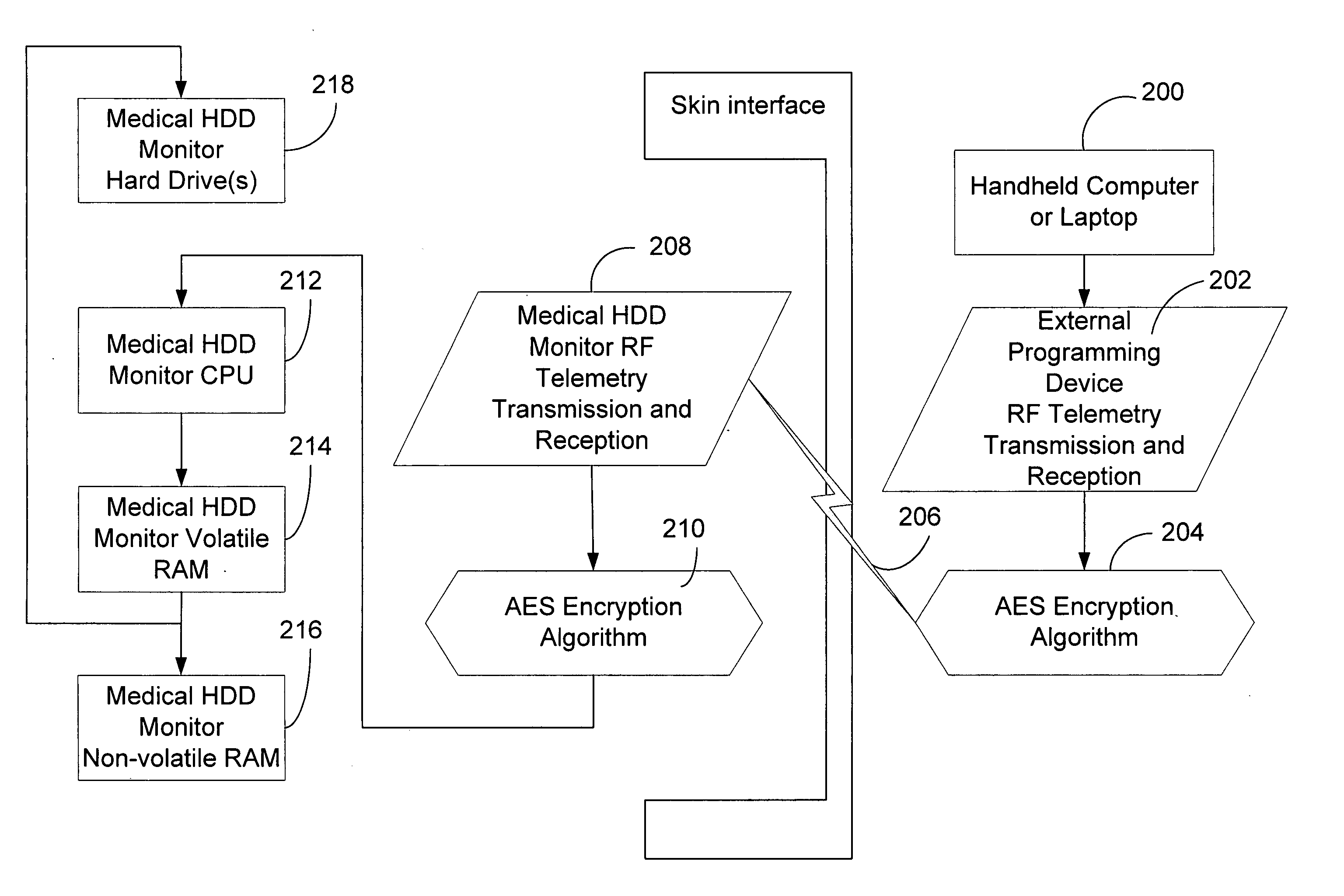

Hard disk drive medical monitor with security encryption

InactiveUS20050288737A1High currentHigh voltageElectrotherapySurgeryHard disc driveDrug biological activity

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive an enclosure surrounding the at least one hard disk drive, and a transmitter and receiver for producing and transmitting signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one hard disk drive, wherein transmissions are encrypted as encrypted information for security of the user.

Owner:WESTERN DIGITAL TECH INC

Hard disk drive medical monitor with alert signaling system

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver produces and receives signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive. An alert mechanism which is used to signal the user of medical and maintenance conditions is included.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Rechargeable hard disk drive medical monitor

InactiveUS7201719B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveElectrical battery

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes an enclosure surrounding at least one hard disk drive, and also includes a transmitter and a receiver for producing and transmitting signals in the radio frequency range. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the one or more hard disk drives. It also includes a recharging system including at least one rechargeable battery and an induction electronics interface.

Owner:WESTERN DIGITAL TECH INC

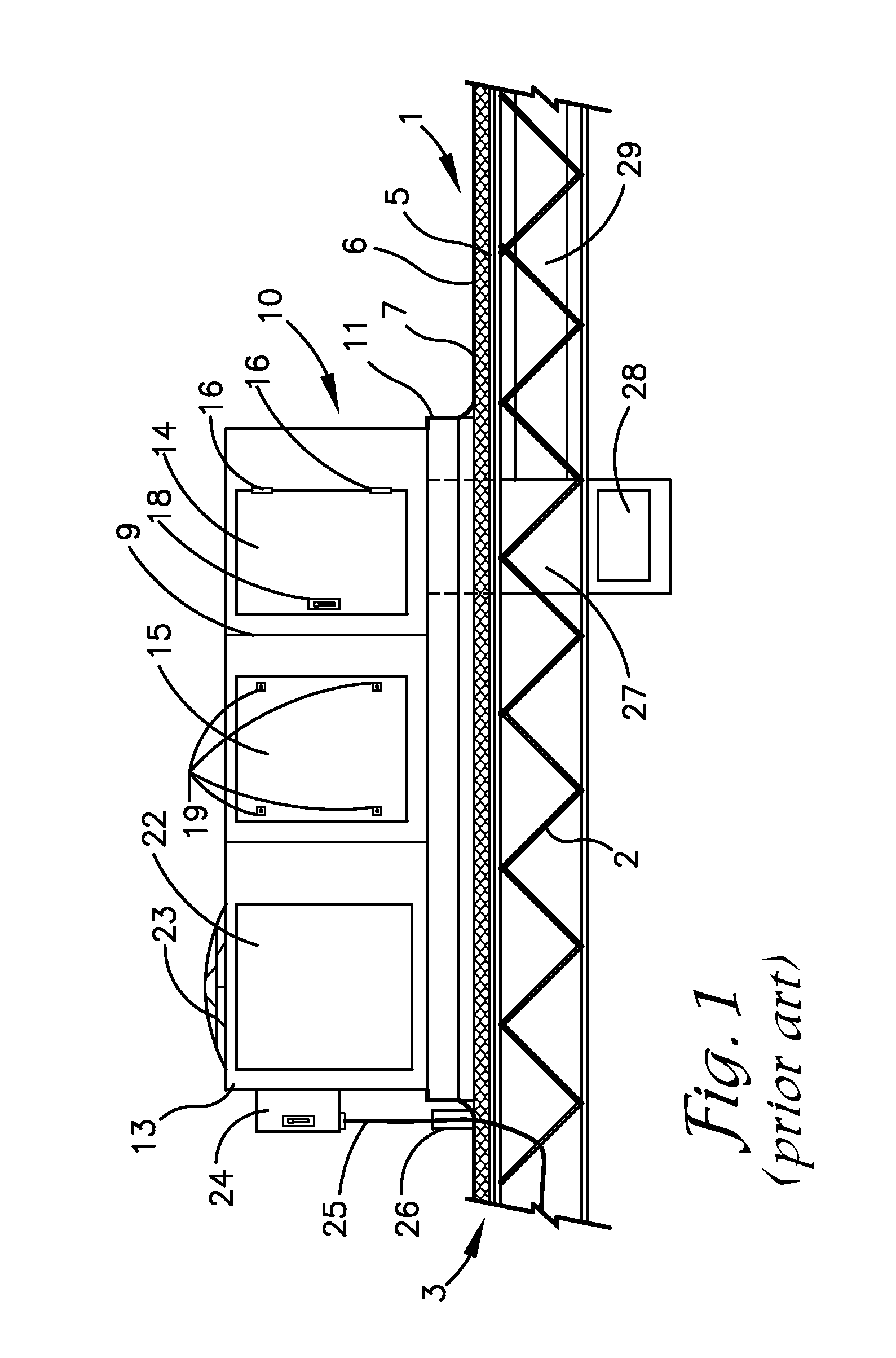

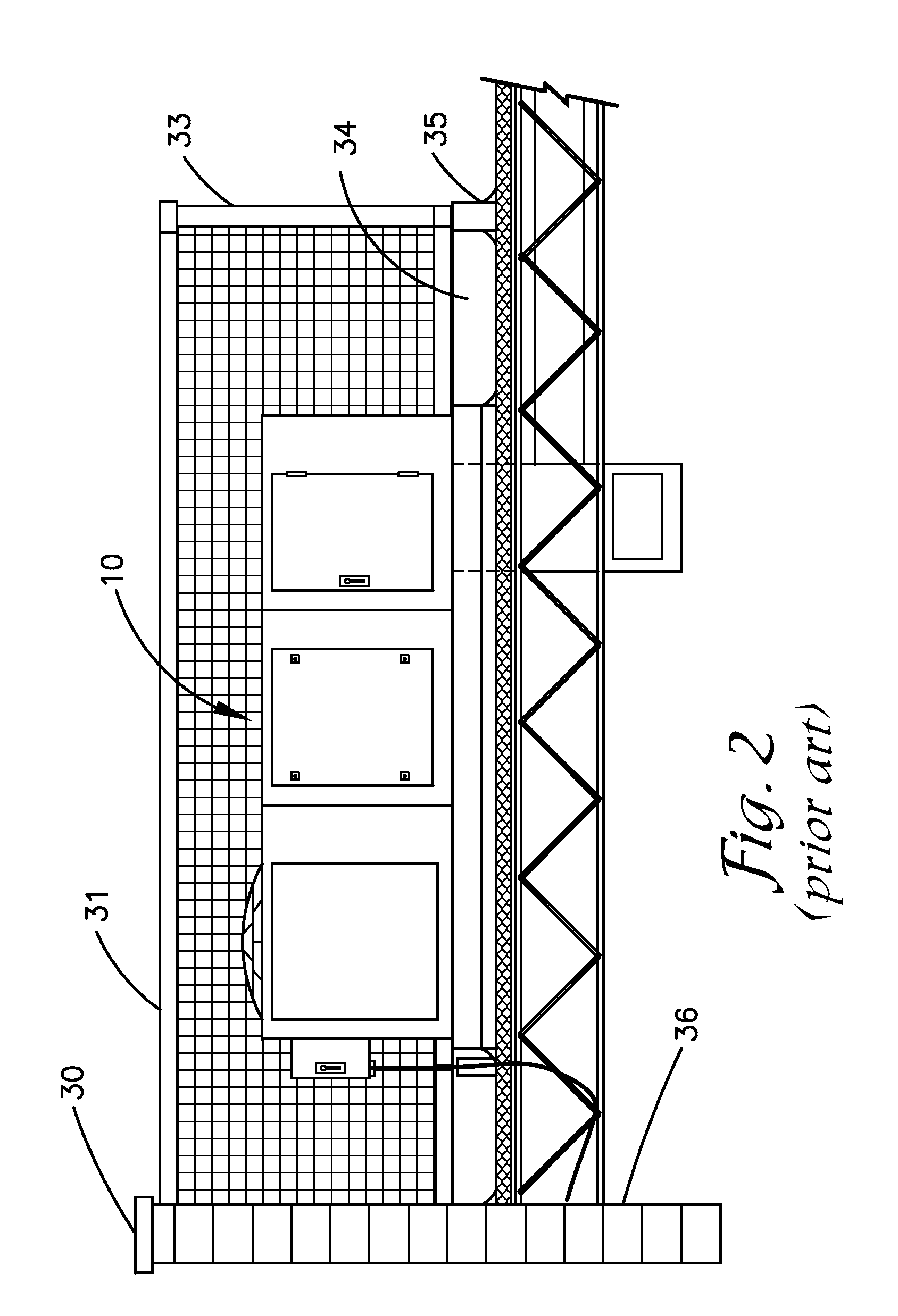

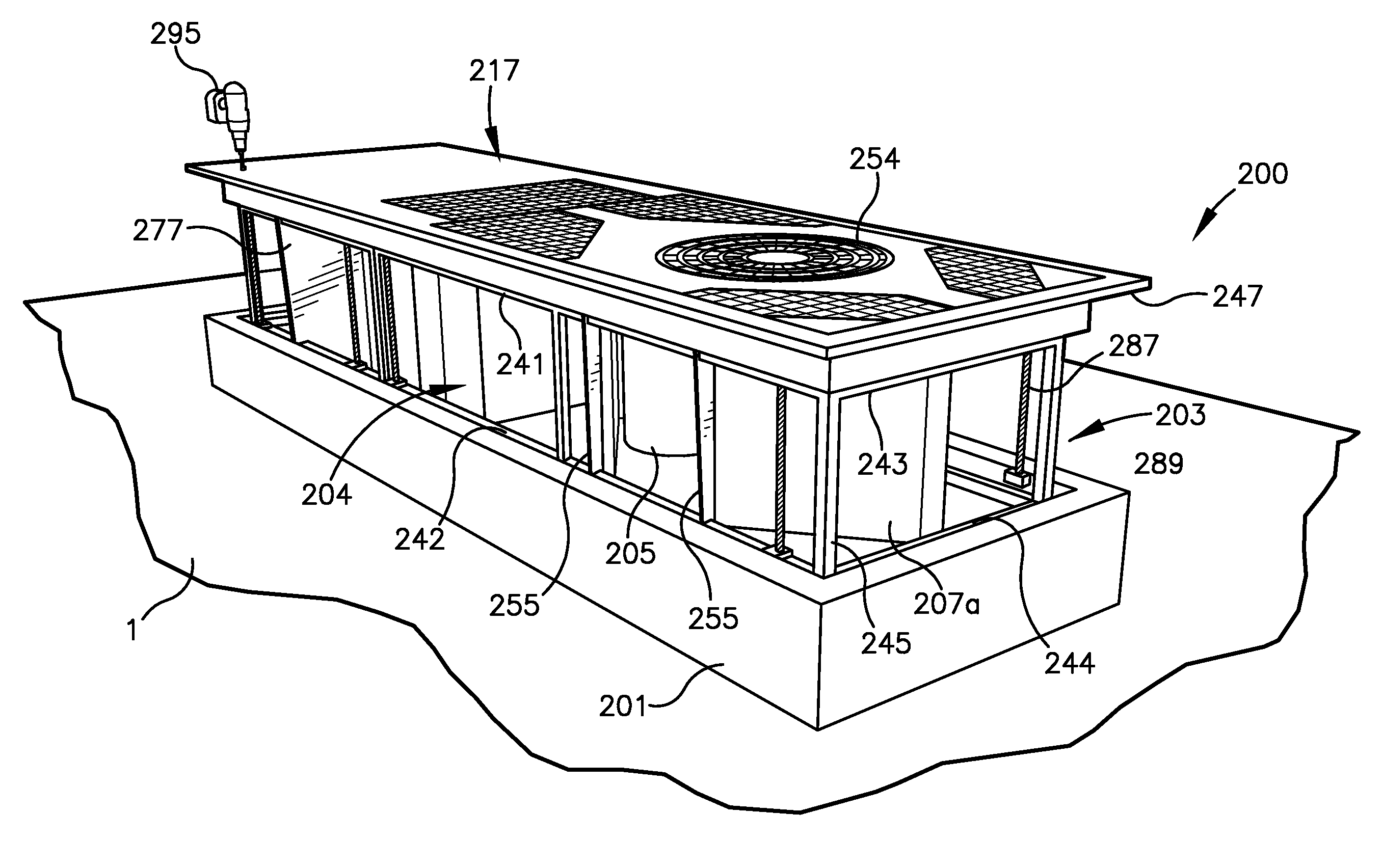

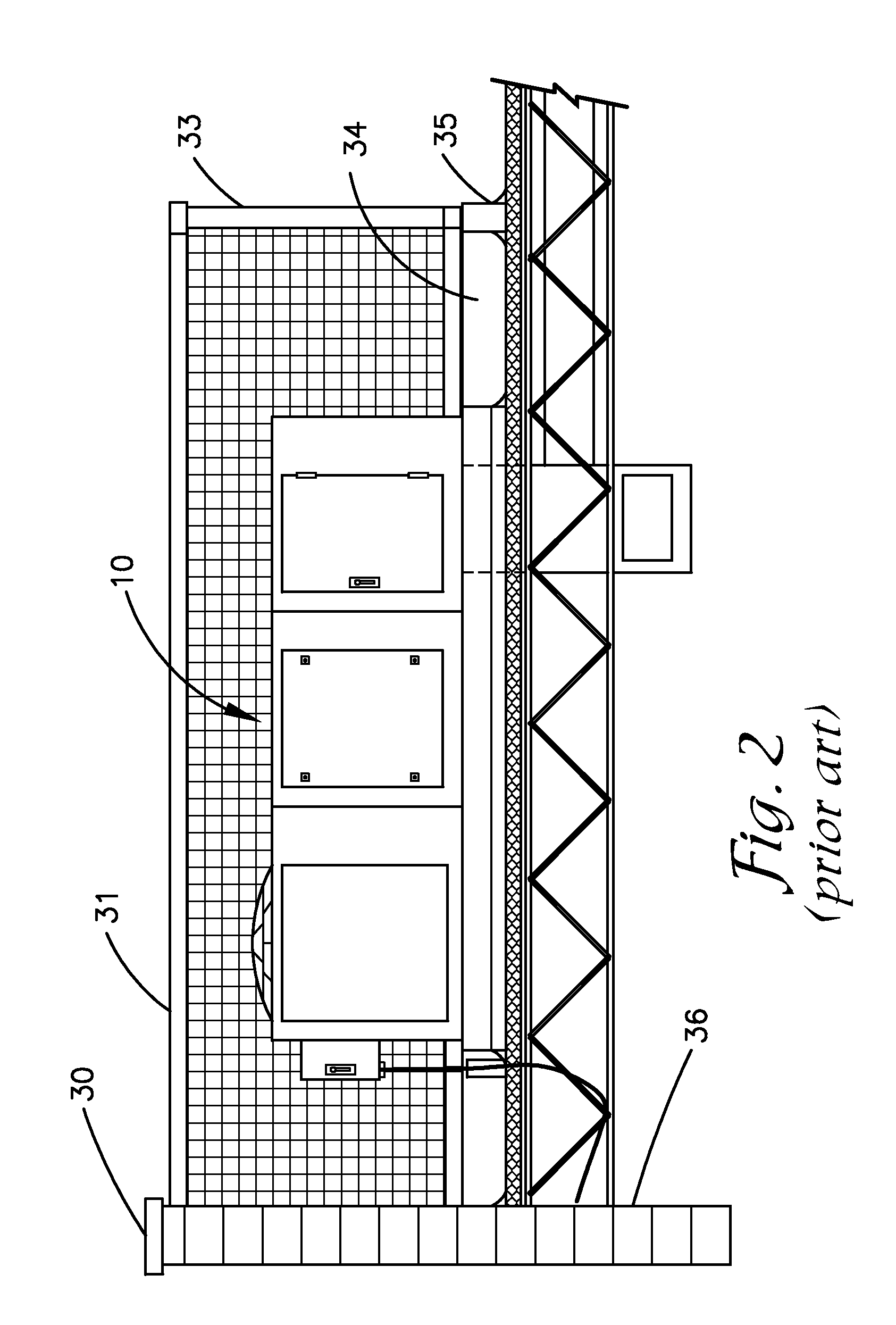

Equipment enclosure and method of installation to facilitate servicing of the equipment

InactiveUS20140196385A1Reduce in quantityReduce energy lossRoof covering using slabs/sheetsBuilding roofsMechanical equipmentEmbedded system

An equipment enclosure system includes an equipment enclosure mounted through a hole in a roof and a chassis supporting the mechanical equipment and which is moveable between a lowered position within the enclosure and a raised position relative to the enclosure to provide access to said equipment. A cover mounted on chassis advances into covering relationship over the enclosure when the chassis is retracted.

Owner:DEMSTER STANLEY J

Equipment enclosure and method of installation to facilitate servicing of the equipment

InactiveUS9291356B2Minimize exposureImprove aestheticsBuilding roofsLighting and heating apparatusEmbedded systemChassis

An equipment enclosure system includes an equipment enclosure mounted through a hole in a roof and a chassis supporting the mechanical equipment and which is moveable between a lowered position within the enclosure and a raised position relative to the enclosure to provide access to said equipment. A cover mounted on chassis advances into covering relationship over the enclosure when the chassis is retracted.

Owner:DEMSTER STANLEY J

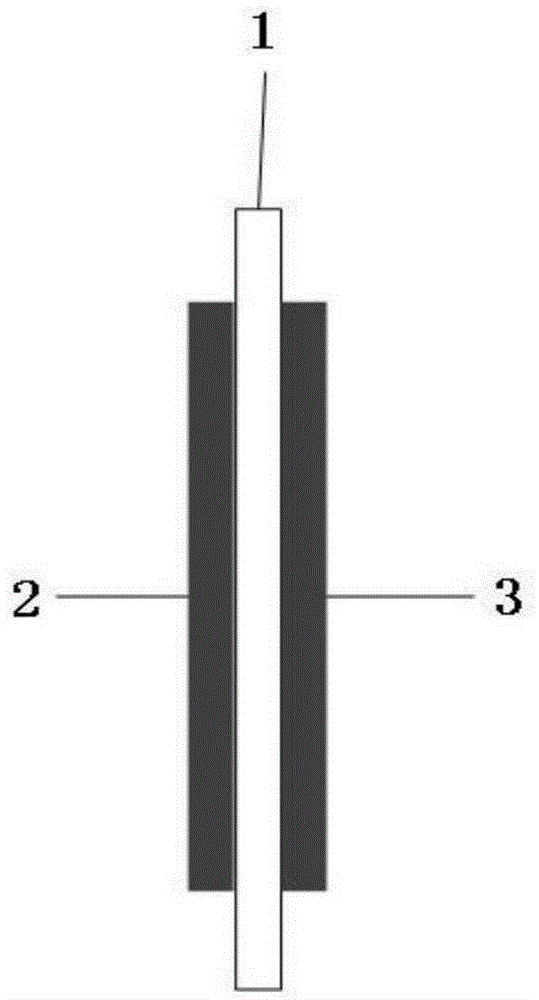

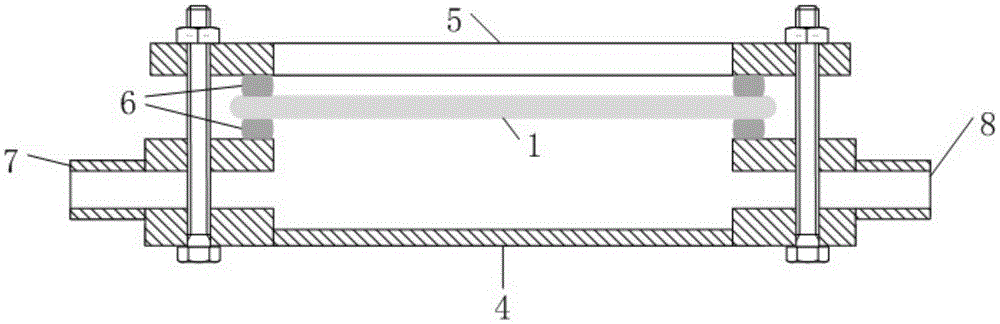

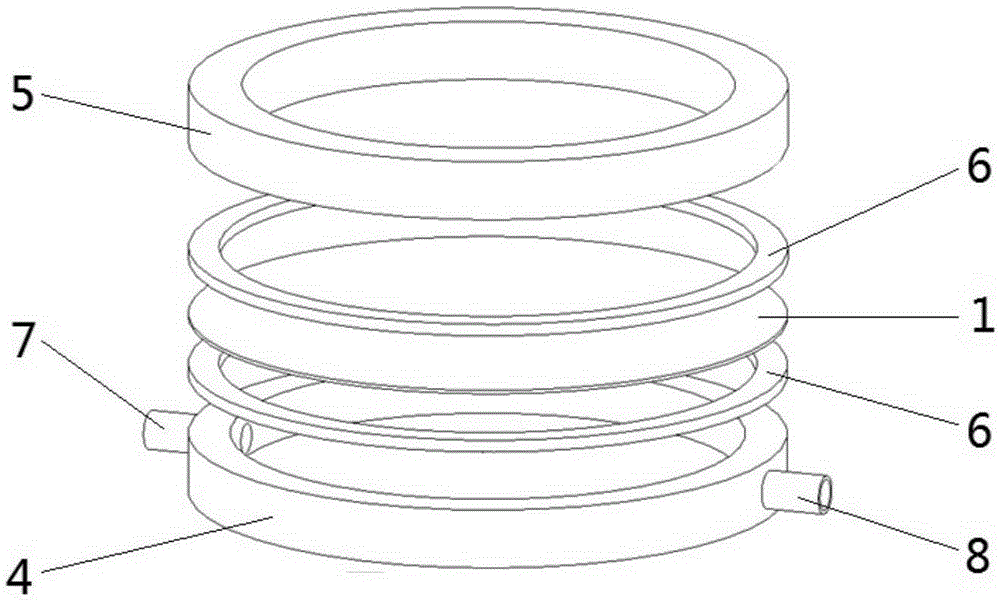

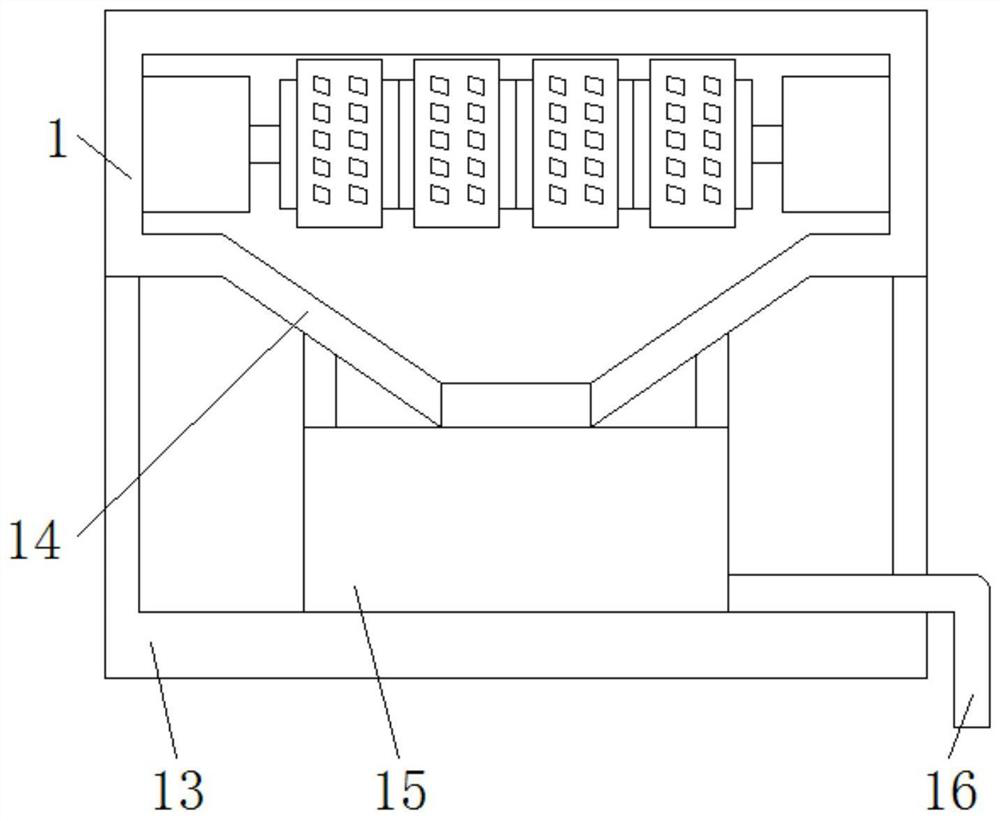

Preparing method of membrane electrode in solid polymer water electrolyser and device for implementing method

The invention provides a preparing method of a membrane electrode in a solid polymer water electrolyser. Two catalyst layers are formed on the two faces of a solid polymer electrolyte membrane respectively. At least one catalyst layer is formed in the following method that one side of the solid polymer electrolyte membrane makes contact with pure water with the temperature of 50-95 DEG C, the solid polymer electrolyte membrane is evenly heated through the water temperature, and when the membrane is kept in a swelling state, the face, not making contact with water, of the membrane is loaded with catalyst ink, and the catalyst layer is formed. The membrane electrode manufactured through the method has good uniformity and is more superior than membrane electrode manufactured through a traditional CCM method in performance. The invention further provides a device for implementing the method.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Hard disk drive medical monitor with alert signaling system

InactiveUS7247136B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveSignaling system

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver produces and receives signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive. An alert mechanism which is used to signal the user of medical and maintenance conditions is included.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

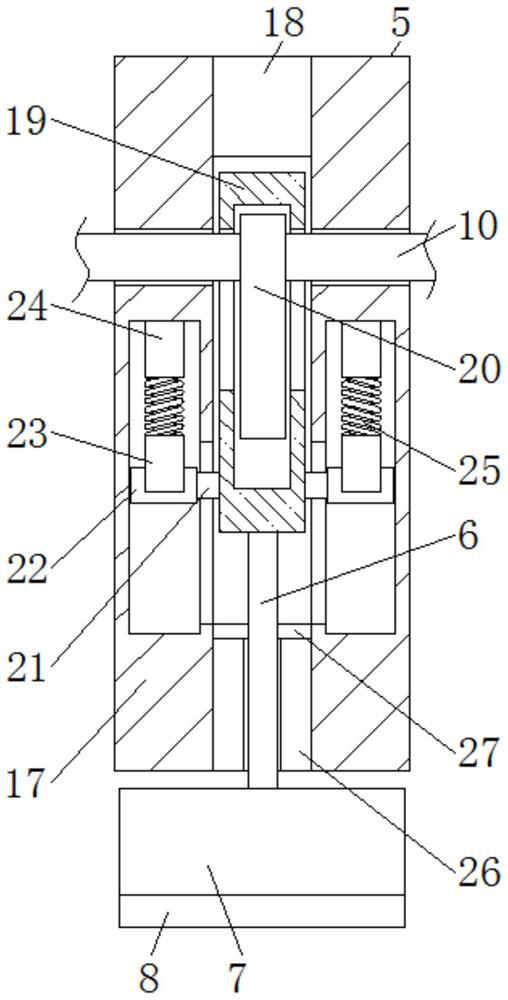

Hard disk drive medical monitor with shock-proofing

InactiveUS7338445B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveComputer science

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver for produces and transmits signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive, where the enclosure includes a shock-proofing system.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Hard disk drive medical monitor with mirrored HDDs

InactiveUS7278967B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveDrug biological activity

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes a primary disk drive and a secondary disk drive, where the secondary disk drive mirrors the primary disk drive. An enclosure surrounds at least one of the primary and secondary drives. A transmitter and receiver for produces and transmits signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the primary disk drive, and the secondary disk drive.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

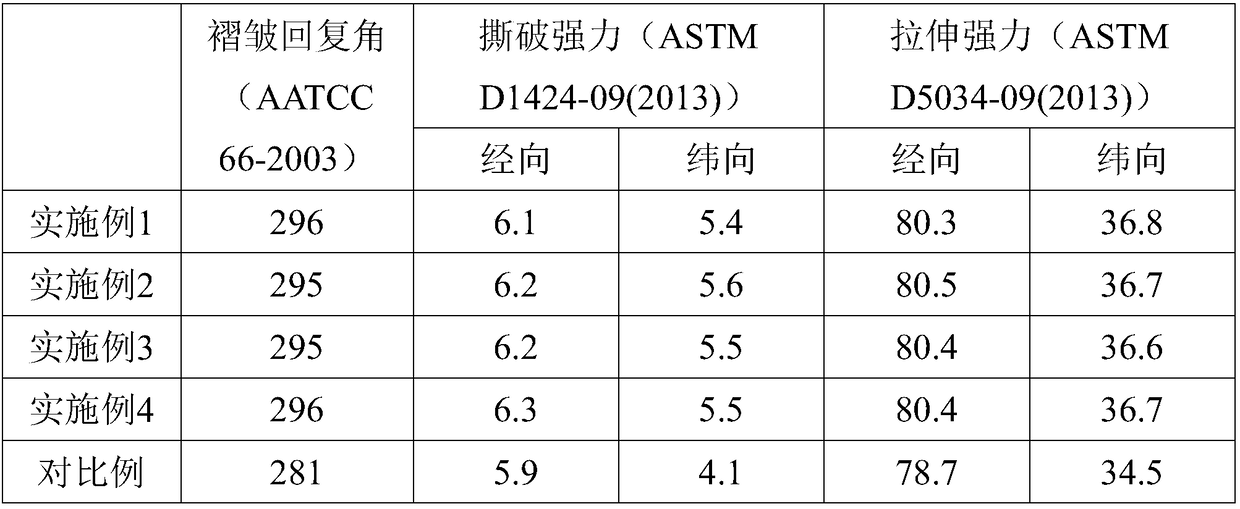

Easy-care treatment method of pure cotton products for clothing

InactiveCN108867068AStable structureReduce volumeLiquid/gas/vapor removalTextile treatment by spraying/projectingPulp and paper industryHardness

The invention discloses an easy-care treatment method of pure cotton products for clothing, and relates to the technical field of processing of pure cotton products. The easy-care treatment method comprises the following steps that (1), a pure cotton product is soaked in water till no water drops, then the pure cotton product is tiled on a leveling working table, a flat board is utilized for pressing the pure cotton product to be flat, and then the pure cotton product is hung and erected; (2) an easy-care treatment agent is added into the water with the weight being 30-40 times to be blended uniformly, and an atomizer is utilized for atomizing and spraying the mixed liquid onto the erected pure cotton product; (3) the pure cotton product where the easy-care treatment agent is sprayed is roasted by a roaster; and (4) the roasted pure cotton product is put into saturated vapor pressure with the temperature being 130 DEG C and the pressure being 0.27 Mpa to be subjected to soaking and steaming, after being cooled, the pure cotton product is tiled on the leveling working table, and then heated and dried through radiation of high infrared rays; and after being subjected to easy-care treatment by the certain easy-care treatment agent, the pure cotton product can maintain the shape when being processed into clothes, ironing is reduced, the gas permeability, the strength and the hardness of the pure cotton product can be kept, and the wearing comfort is not reduced.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Hard disk drive medical monitor with mirrored HDDs

InactiveUS20050288562A1Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveDrug biological activity

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes a primary disk drive and a secondary disk drive, where the secondary disk drive mirrors the primary disk drive. An enclosure surrounds at least one of the primary and secondary drives. A transmitter and receiver for produces and transmits signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the primary disk drive, and the secondary disk drive.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Hard disk drive medical monitor with electrical grounding system

InactiveUS7201718B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveElectricity

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver produces and receives signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive, and an electrical grounding system is included.

Owner:WESTERN DIGITAL TECH INC

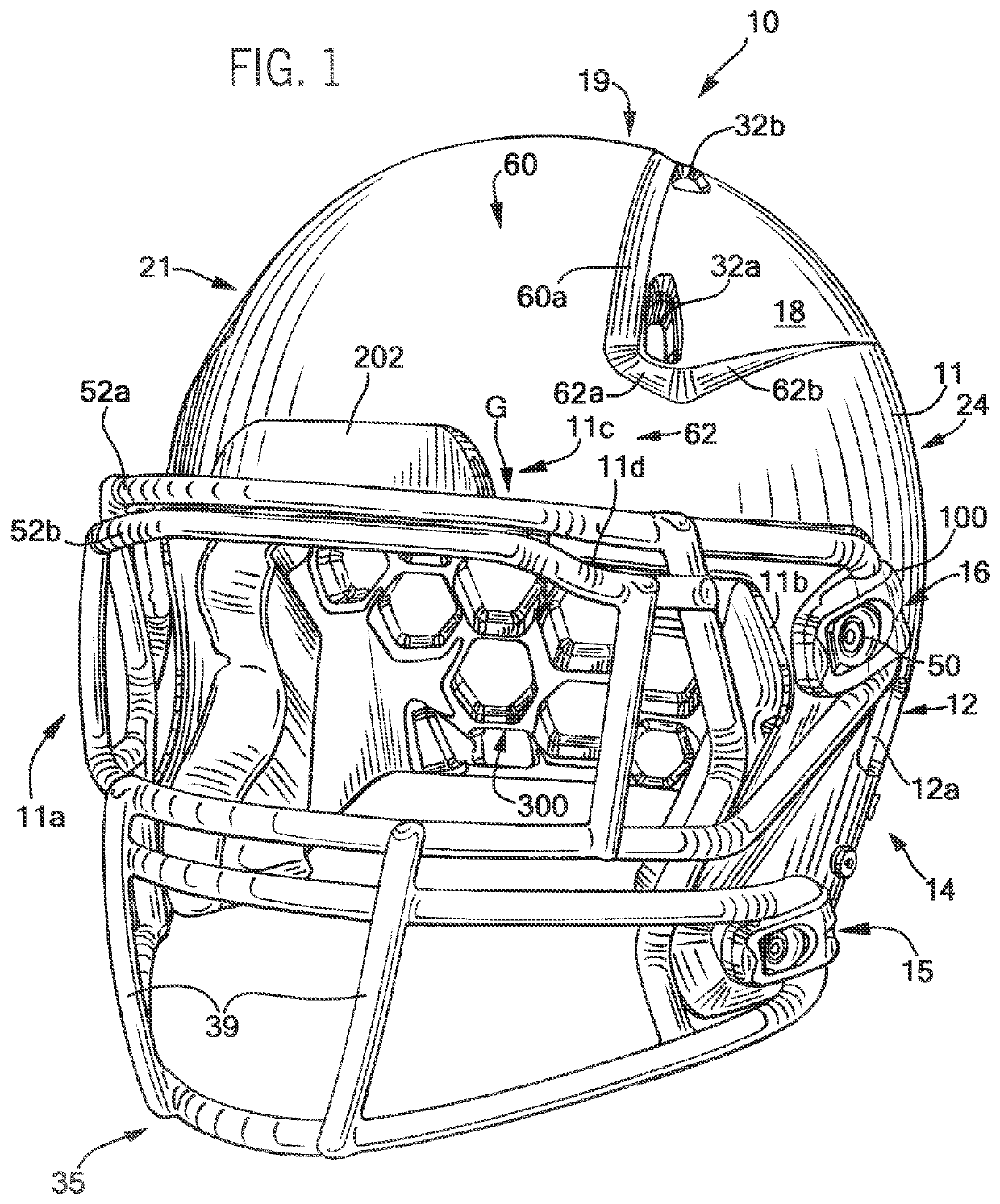

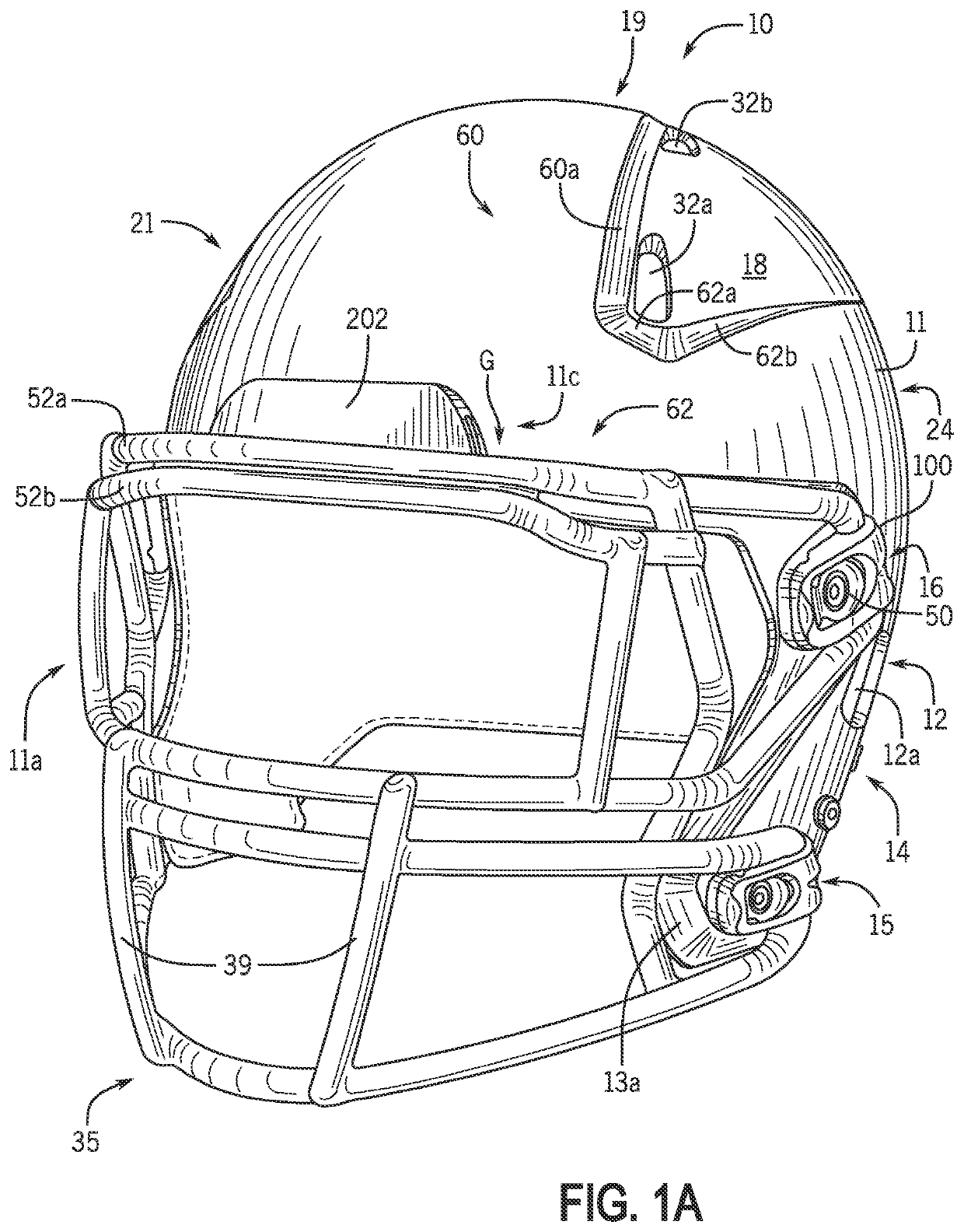

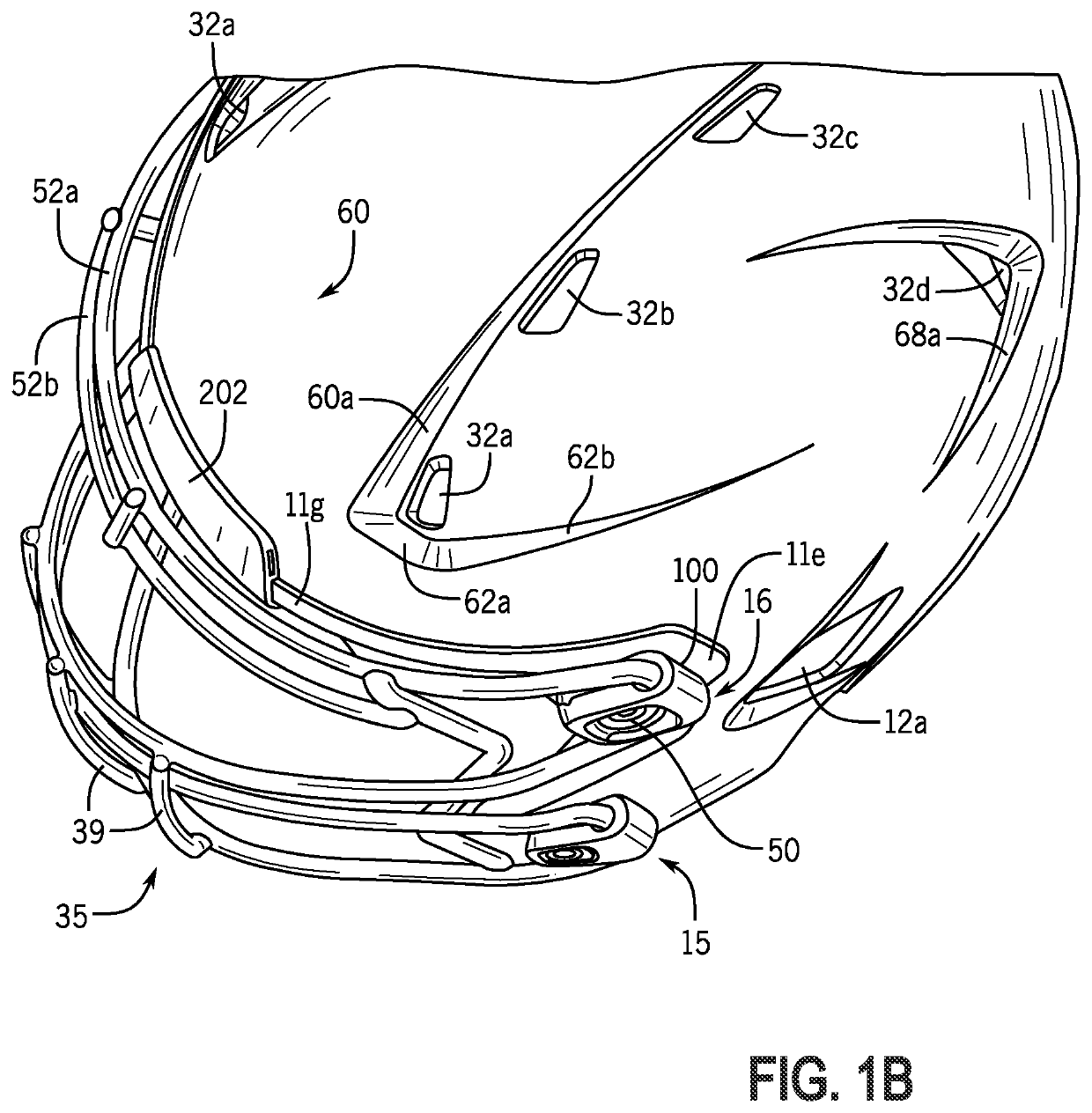

Protective sports helmet

InactiveUS20220061448A1Protective naturePrevent neck injuriesBall sportsHelmetsEngineeringMechanical engineering

A protective sports helmet that includes an energy attenuating faceguard connection system, which includes at least one connector that secures the faceguard to the helmet shell without a connection point in the shell's brow region. The lack of a brow region connection point results in a gap or clearance between the faceguard and the shell that has a functional interplay with the connector upon an impact to the faceguard. In general terms, when a substantially on-center impact to the faceguard occurs, the faceguard is displaced towards the shell and the connector bracket flexes outward relative to the helmet shell to help dissipate impact energy.

Owner:RIDDELL

Non-ironing treatment method for chemical fiber fabric

InactiveCN108867067AStable structureReduce volumeFibre treatmentLiquid/gas/vapor removalFiberHardness

The invention discloses a non-ironing treatment method for chemical fiber fabrics, which relates to the technical field of the processing of the chemical fiber fabrics. The non-ironing treatment method comprises the following steps: (1) wetting the chemical fiber fabric by using water until the chemical fiber fabric is in a non-dripping state, laying the chemical fiber fabric on a smooth working table-board, flattening the chemical fiber fabric by using a flat plate, then suspending and erecting the chemical fiber fabric; (2) uniformly mixing a non-ironing treatment agent in 30 to 40 times ofwater, and atomizing and spraying the non-ironing treatment agent on the erected chemical fiber fabric by using an atomizer; (3) baking the chemical fiber fabric with the non-ironing treatment agent by using a baking machine; and (4) soaking and steaming the baken chemical fiber fabric under the saturated steam of 130 DEG C and 0.27Mpa, cooling, laying on a flat working table-board, and heating and drying by virtue of the radiation of high infrared rays; and performing the non-ironing treatment for a special treatment agent, processing the chemical fiber fabric to form clothing, cleaning the clothing to keep the shape, so that the ironing can be reduced; and gas permeability, strength and hardness of the chemical fiber fabric can be maintained, and the wearing comfort degree can be reduced.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Rechargeable hard disk drive medical monitor

InactiveUS20050288561A1High currentHigh voltageElectrotherapySurgeryHard disc driveElectrical battery

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes an enclosure surrounding at least one hard disk drive, and also includes a transmitter and a receiver for producing and transmitting signals in the radio frequency range. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the one or more hard disk drives. It also includes a recharging system including at least one rechargeable battery and an induction electronics interface.

Owner:WESTERN DIGITAL TECH INC

Hard disk drive medical monitor with shock-proofing

A medical monitor is disclosed for implantation in a human body for monitoring biological activity and states as detected by implanted sensors. The medical monitor includes at least one hard disk drive. A transmitter and receiver for produces and transmits signals. The medical monitor is in communication with the sensors, by which information on biological activity and states is stored on the at least one disk drive. An enclosure surrounds the at least one hard disk drive, where the enclosure includes a shock-proofing system.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

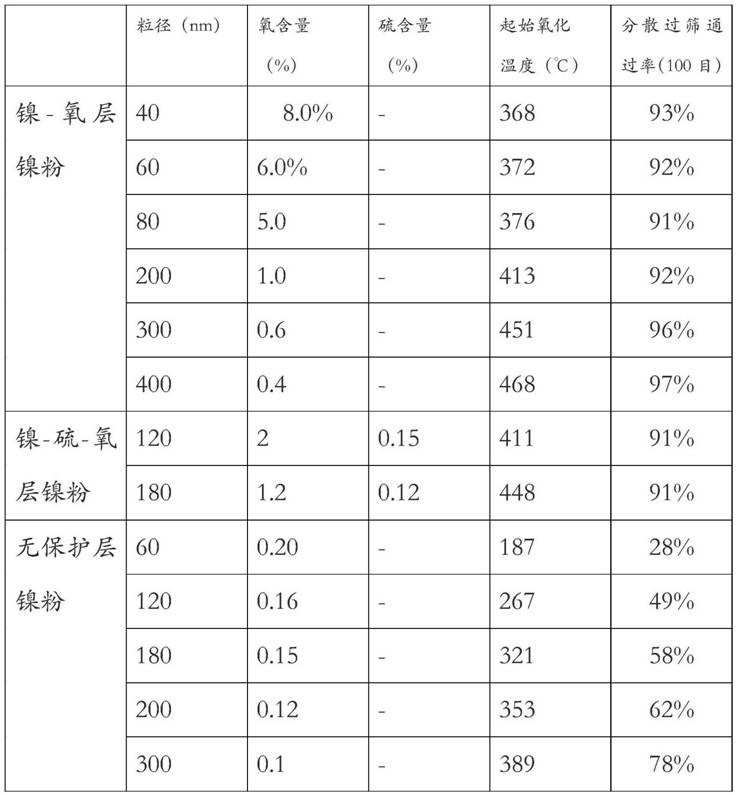

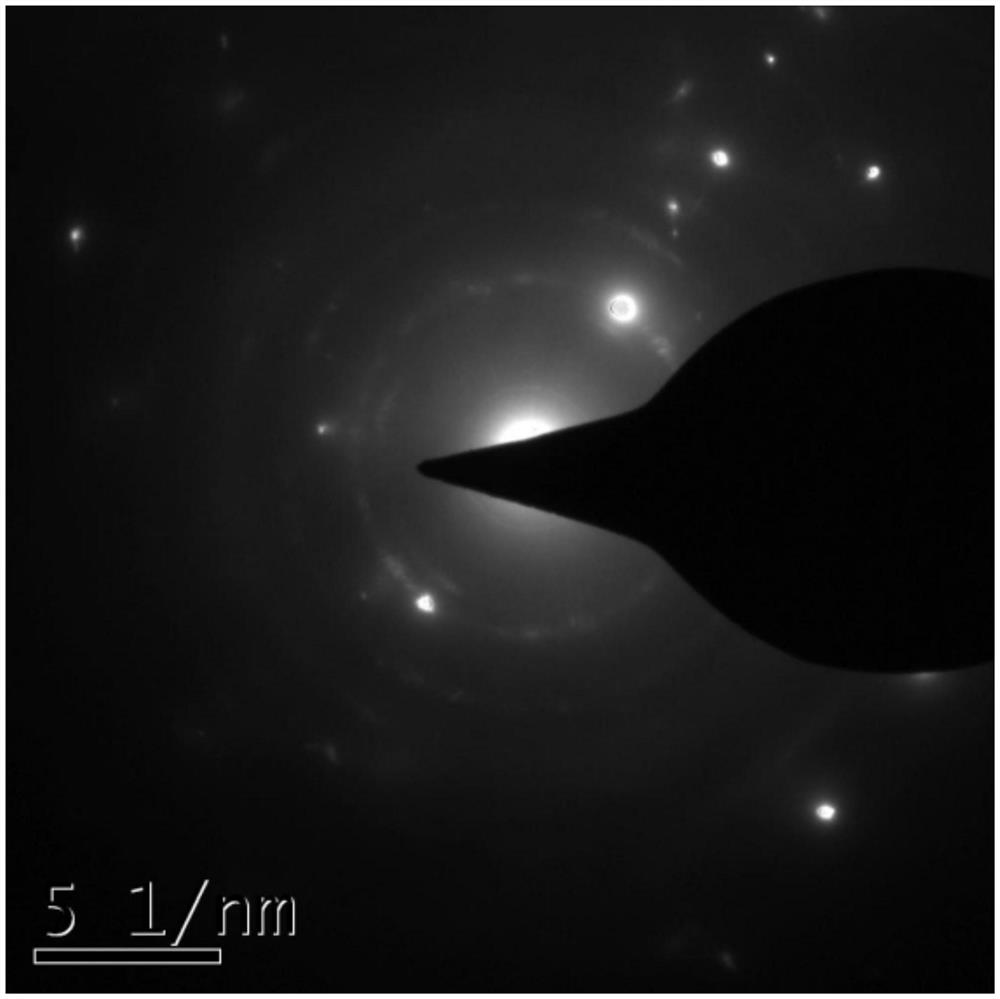

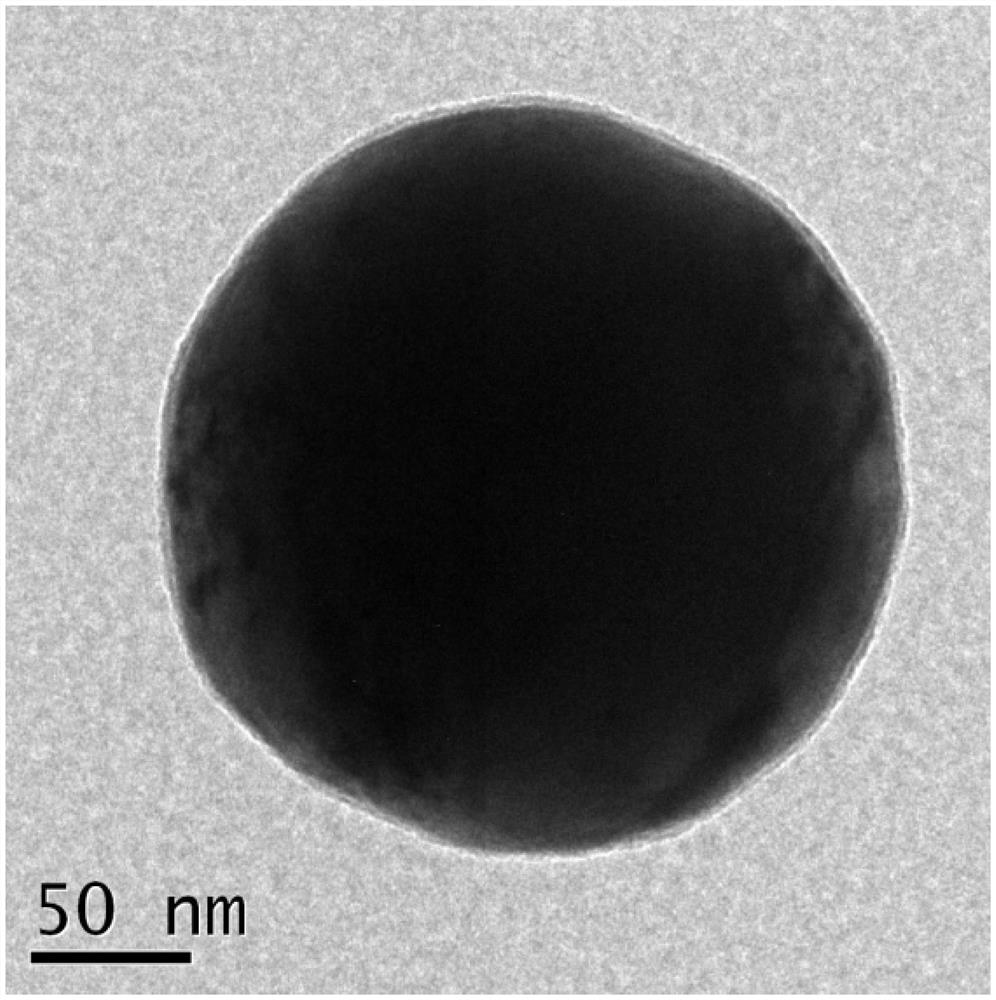

Nano-nickel powder of core-shell structure

PendingCN112872349AImprove the immunityProtective natureMaterial nanotechnologyTransportation and packagingNickel sulfideCarbon dioxide content

The invention discloses a nano-nickel powder of a core-shell structure. The nano-nickel powder comprises a spherical nickel bead and a protecting layer, wherein the outer surface of the spherical nickel bead is coated with the protecting layer, and the protecting layer has the passivation function and the agglomeration-preventing function. The spherical nickel bead is of a crystal structure; the diameter of the spherical nickel bead is 10-600 nanometers; and the thickness of the protecting layer which is a nickel-sulphur-oxygen protecting layer is 0.5-6 nanometers. The nickel-sulphur-oxygen protecting layer comprises 10-25% of nickel sulfide, 50-75% of nickel oxide, 3-10% of nickel hydroxide, basic nickel carbonate, 1-3% of carbon dioxide and 0.1-0.5% of water. The degree of sphericity of the nickel powder is high; the crystal structure is complete; the dispersibility is high; the sintering temperature is high; and the shrinkage rate is low.

Owner:杭州新川新材料有限公司

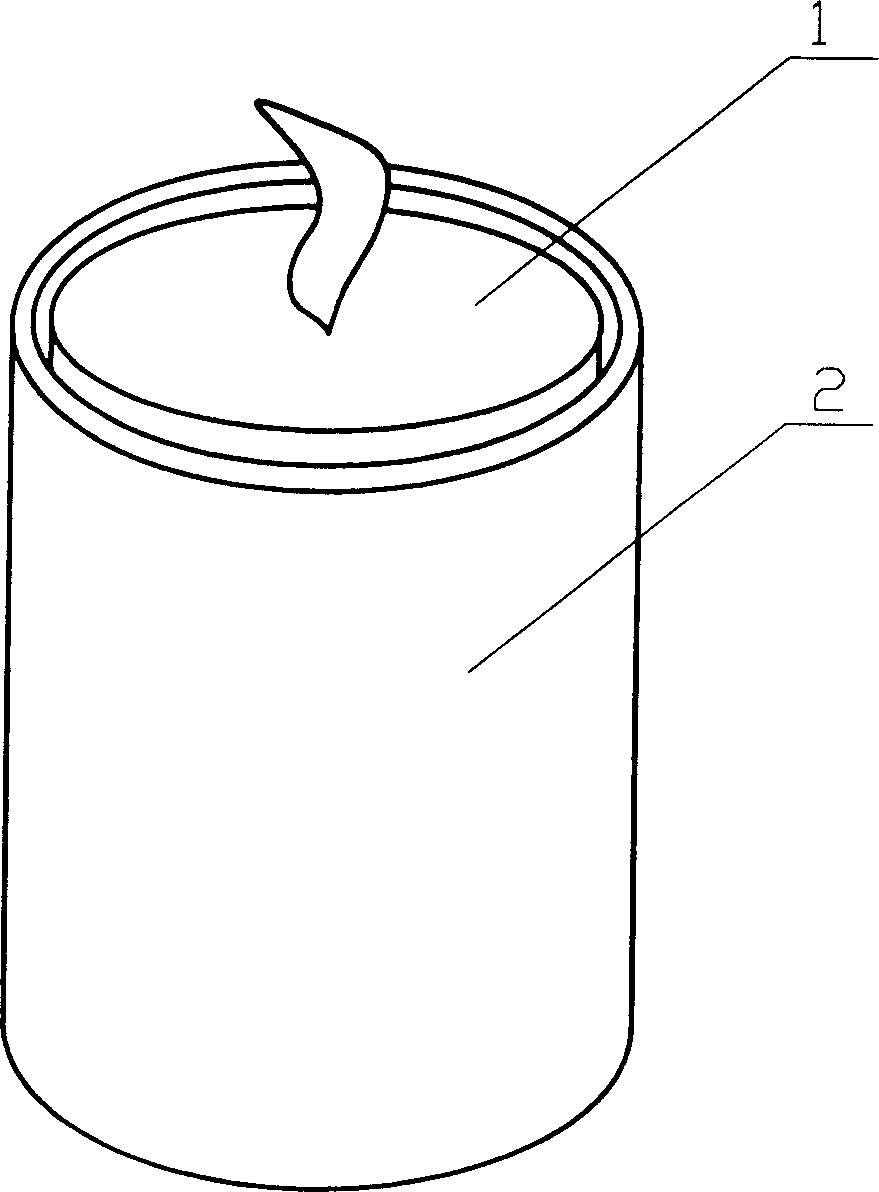

Fly expelling candle and preparing method

The present invention discloses a fly expelling candle and its making process. The fly expelling candle contains pyrethroid of 0.5-1 wt% in wax carrier and may contain also piperonyl butoxide oxide or sesamin in 0.1-0.3 wt% as the synergist. The making process of the fly expelling candle includes melting wax, adding pyrethroid and synergist through stirring, lowering temperature, regulating pH to 6-7, adding wick and forming. The formed fly expelling candle may have casing added. The present invention has excellent fly expelling effect.

Owner:程富川 +1

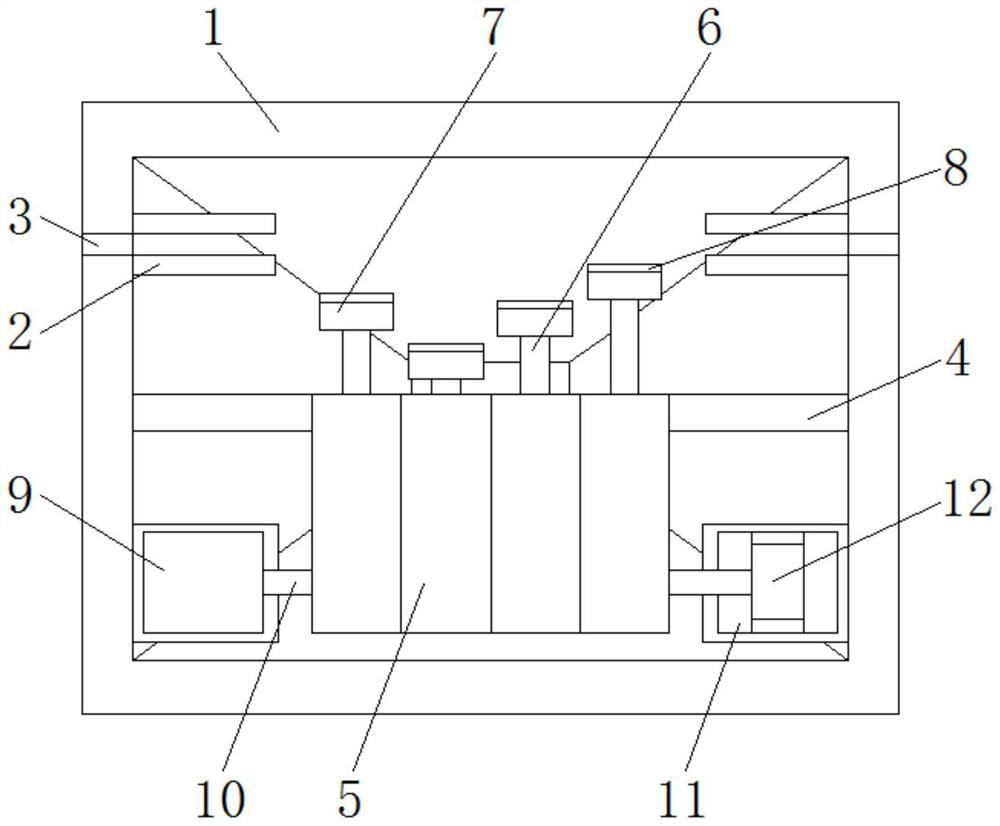

Textile finishing device for linen textile processing

InactiveCN112251960AAvoid rehydrationProtective natureLiquid/gas/vapor removal by squeezingElectric machineryEngineering

The invention relates to the technical field of textile finishing, and discloses a textile finishing device for linen textile processing. The textile finishing device comprises a draining tank, limiting plates are fixedly mounted on the left side and the right side of the inner wall of the draining tank, notches are formed in the left side and the right side of the draining tank, and fixing platesare fixedly mounted on the left side and the right side of the inner wall of the draining tank. Draining parts are fixedly mounted on the inner sides of the fixing plates, movable rods are movably mounted at the top ends of the draining parts, ejector blocks are fixedly mounted at the top ends of the movable rods, pressing plates are fixedly mounted at the top ends of the ejector blocks, a motorbox is fixedly mounted on the inner wall of the left side of the draining tank, and a rotating shaft is fixedly mounted on an output shaft of a motor in the motor box. A base is fixedly mounted on theinner wall of the right side of the draining tank, the textile finishing device for linen textile processing can be directly used on a textile finishing assembly line to drain cloth, water in the cloth is effectively removed, and the situation that when the cloth is dried, the drying efficiency is low due to the fact that the water content is too high is prevented.

Owner:新昌县大市聚镇金丰五金厂

Hard disk drive medical monitor with sound-proofing

InactiveUS7214188B2Protected against corrosion and oxidation behaviorProtective natureElectrotherapySurgeryHard disc driveComputer science

Owner:WESTERN DIGITAL TECH INC

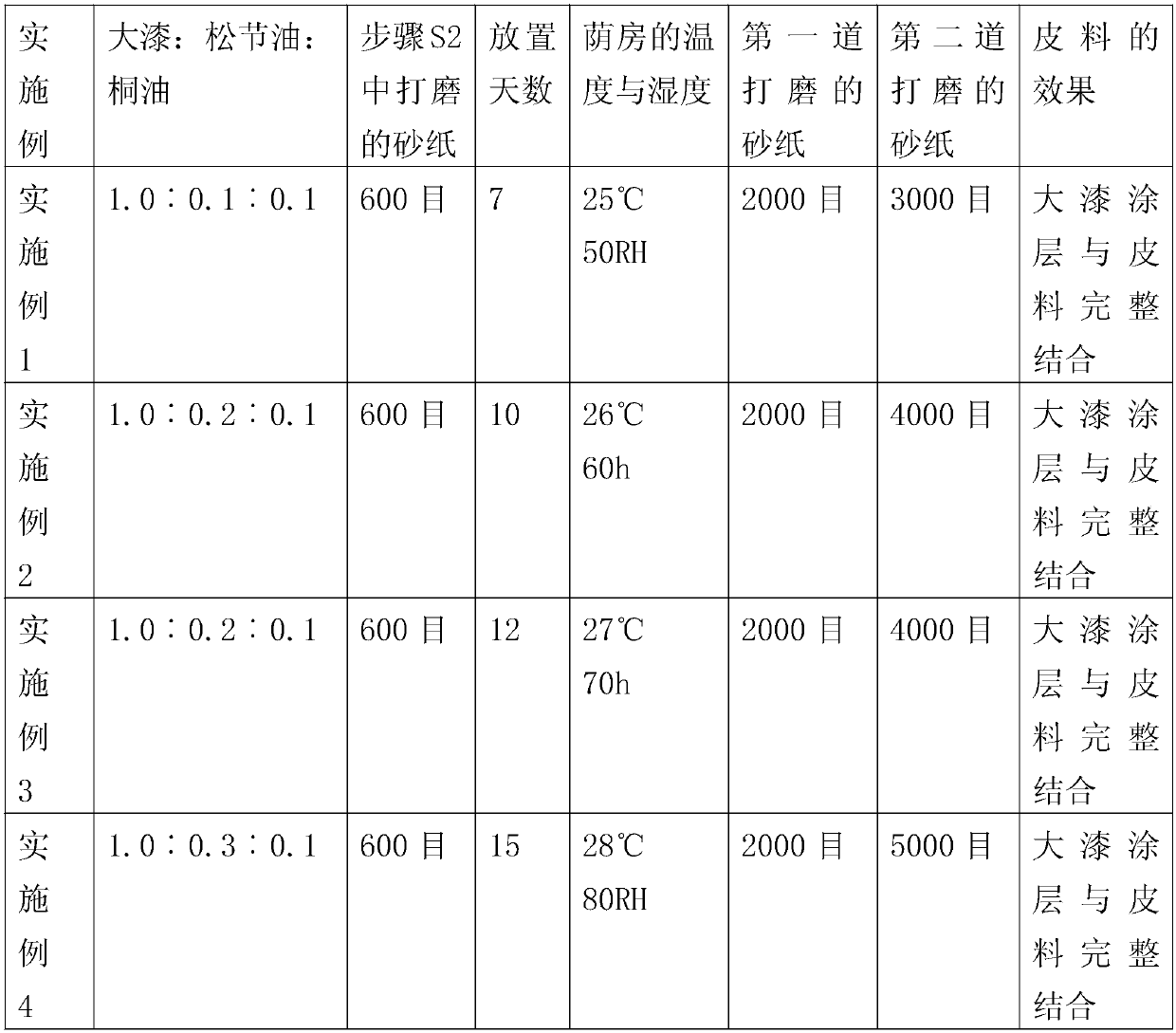

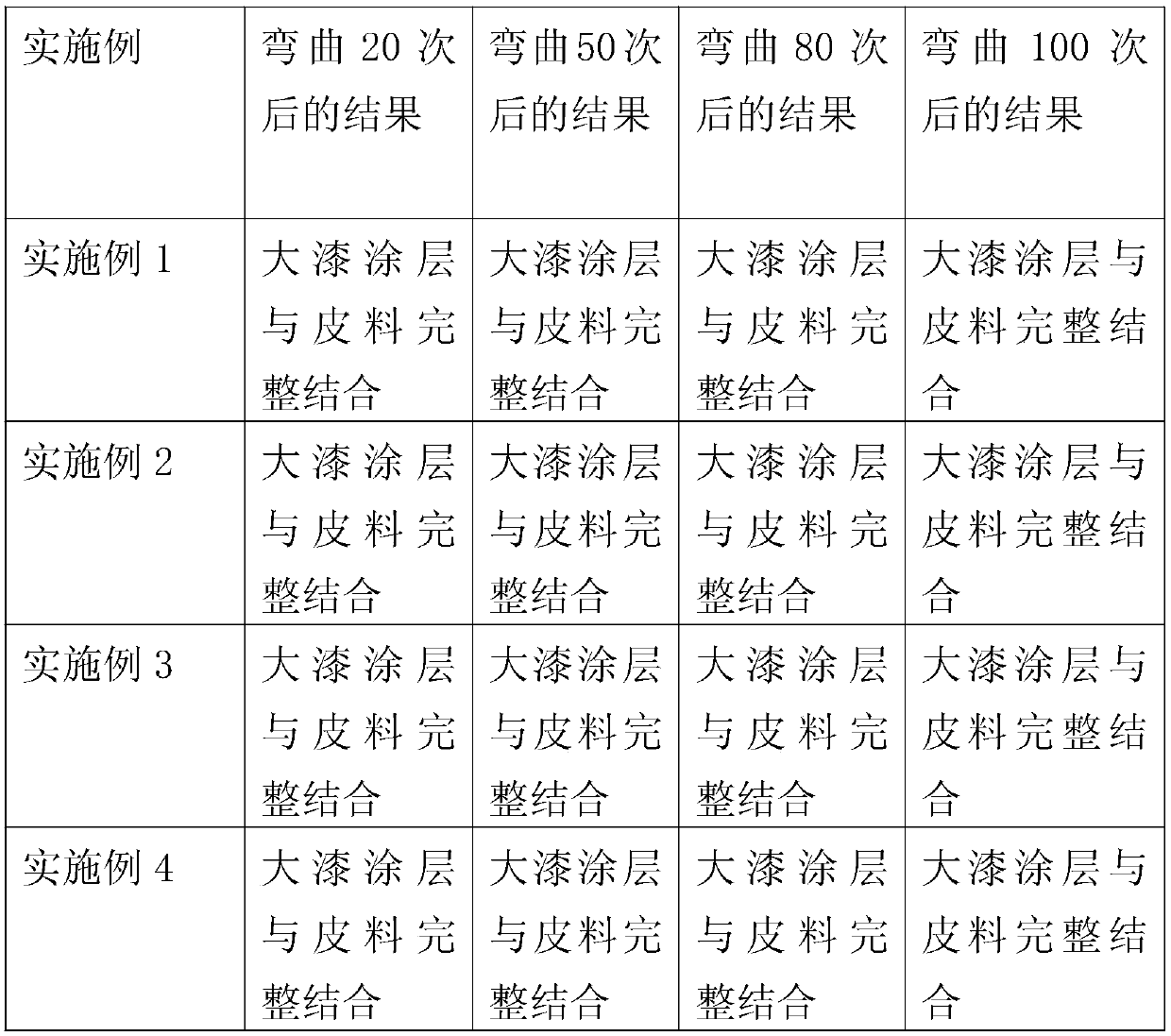

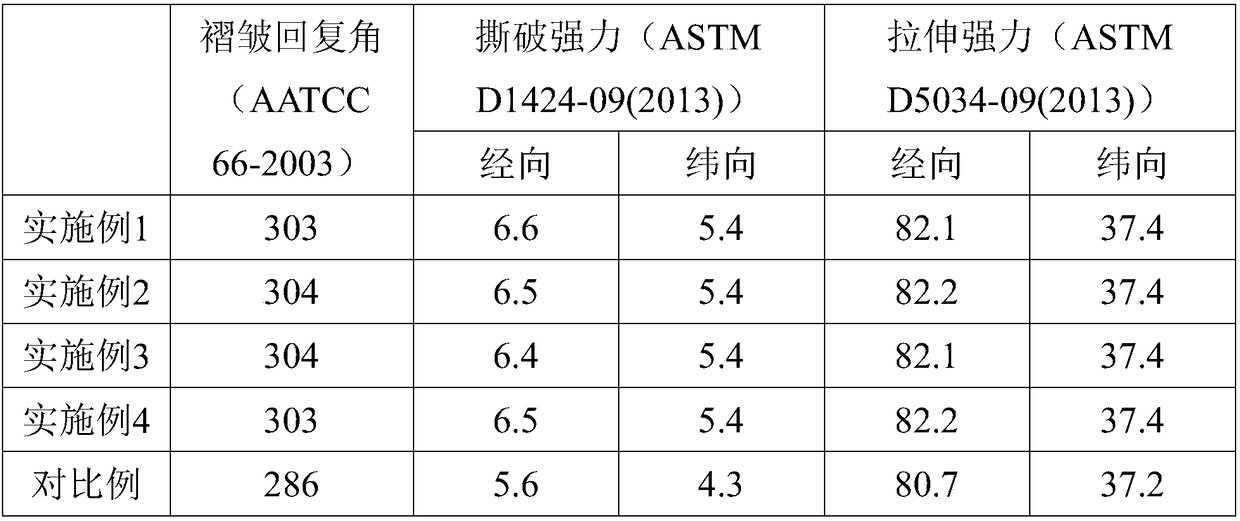

Rubbing polishing treatment method for Chinese lacquer on surface of leather

InactiveCN107828921ARetain textureEasy to solveFur mechanical treatmentLeather surface mechanical treatmentWaxLacquer

The invention relates to a rubbing polishing treatment method for Chinese lacquer on the surface of leather. The rubbing polishing treatment method comprises the following steps that S1, the Chinese lacquer, turpentine oil and tung oil are uniformly mixed proportionally, and Chinese lacquer paint is prepared; S2, wax or oil on the skin layer of the surface of the leather is polished with abrasivepaper, and the leather is pretreated; S3, the Chinese lacquer paint is completely smeared on the surface of the leather, and the leather is put at a cool and wet place to be naturally dried after sufficiently absorbs the Chinese lacquer paint; S4, after the leather is put at the place for some days, the Chinese lacquer paint is completely solidified on the surface of the leather and forms a Chinese lacquer coating layer, primary polishing is conducted on the solidified Chinese lacquer coating layer through the adhesive paper so that a lacquer film covering the surface can be removed, and then,secondary polishing is conducted the solidified Chinese lacquer coating layer through the adhesive paper; and S5, after the solidified Chinese lacquer coating layer is polished to be smooth, the leather is cleaned with clean cloth, and buffing is conducted. According to the rubbing polishing treatment method, the Chinese lacquer and the leather are combined, a lacquer-leather combining layer is formed on the surface of the leather, and the artistry and value of the leather are improved.

Owner:福州三分慵懒文化传播有限公司

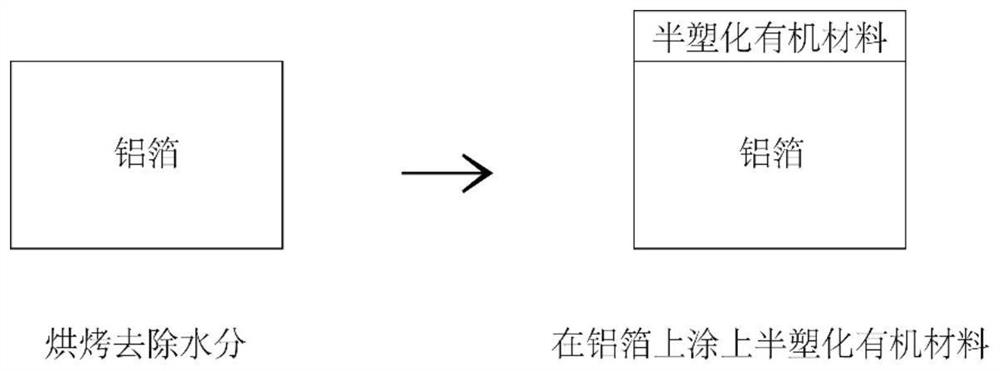

Surface treatment aluminum foil curing process

PendingCN114345668AStable in natureStrong durabilityPretreated surfacesCoatingsMetallurgyAluminum foil

The invention discloses a surface treatment aluminum foil curing process which comprises the following steps: firstly, after surface treatment of an aluminum foil, baking the aluminum foil in a specific temperature area to remove moisture and other components on the surface of the aluminum foil so as to achieve the purpose of curing the aluminum foil; and secondly, a layer of semi-plasticized organic material is added on the surface of the aluminum foil. The surface of the aluminum foil is cured, the performance of the surface of the aluminum foil is improved, the aluminum foil becomes stable, the surface treatment effect is not prone to being reduced, and the quality of the aluminum foil is improved.

Owner:深圳市安博瑞新材料科技有限公司

Method for preparing smell-removed radish red pigment

InactiveCN106810902AEffectively removes odorous substancesRemove odor substancesNatural dyesCelluloseFiltration

The invention discloses a preparation method of deodorized radish red pigment, which comprises extraction under acidic conditions, leaching at room temperature under acidic conditions, enzymatic hydrolysis to remove pectin and cellulose substances, and obtaining clarified red radish clear liquid through filtration and centrifugation. Concentrate the clarified liquid into the ultrafiltration equipment until the color value is 3-4A, then let it stand and centrifuge to further remove impurities in the pigment liquid; then add vegetable oil to stir and mix and layer, the pigment is dissolved in the water phase, and the separated Add ethyl acetate to the water phase after the layer, stir and mix, remove the residual vegetable oil, then concentrate the pigment liquid after removing the vegetable oil under reduced pressure, remove the residual ethyl acetate in the pigment liquid, and concentrate the pigment liquid to 15-20A , the radish red pigment without aftertaste can be obtained; the preparation method of the invention is simple, the deodorizing effect is good, and the application range of the radish red pigment is greatly improved.

Owner:WUHAN GREEN FOOD BIOLOGICAL ENG

Preparation method of non-ironing finishing agent for chemical fiber fabric

The invention discloses a preparation method of a non-ironing finishing agent for chemical fiber fabric, and relates to the technical field of processing of chemical fiber fabric. The preparation method of the non-ironing finishing agent for the chemical fiber fabric comprises the following steps: (1) putting polyester type polyurethane into a ball mill and performing ball milling; (2) mixing acrylic acid, bisphenol A type epoxy resin, fatty acid diethanolamide and poly(p-phenylformamide) uniformly, performing ultrasonic treatment, shifting to a magnesium chloride solution, performing ultrasonic treatment, cleaning and drying; (3) mixing benzoyl peroxide, sucrose fatty acid ester and pentaerythritol fatty acid ester uniformly, sintering, cooling and performing treatment under saturated vapor pressure; (4) mixing the prepared mixtures uniformly, adding into a mixed solution of ethanol and water, adding sodium sulphite, sodium secondary alkyl sulfate and ammonium hydrogen carbonate, mixing uniformly and adjusting PH to prepare the non-ironing finishing agent. The non-ironing finishing agent can achieve the non-ironing effect, can maintain the original strength, hand feeling comfortability as well as moisture absorbing and air-permeable properties of the chemical fiber, and guarantees the wearing comfortability.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com