Nano-nickel powder of core-shell structure

A technology of nano-nickel powder and core-shell structure, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of electrode layer short-circuit withstand voltage, rupture, drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

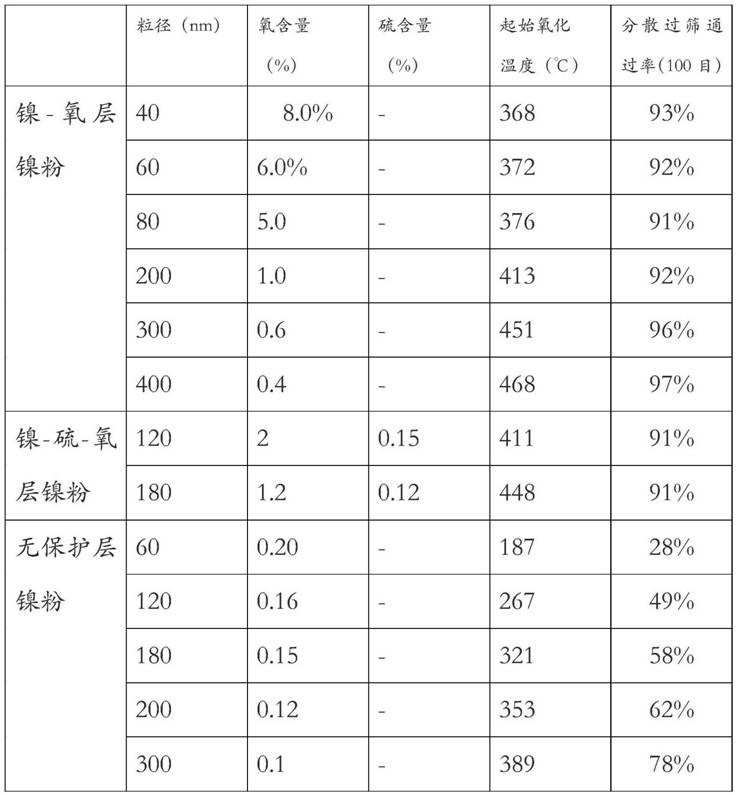

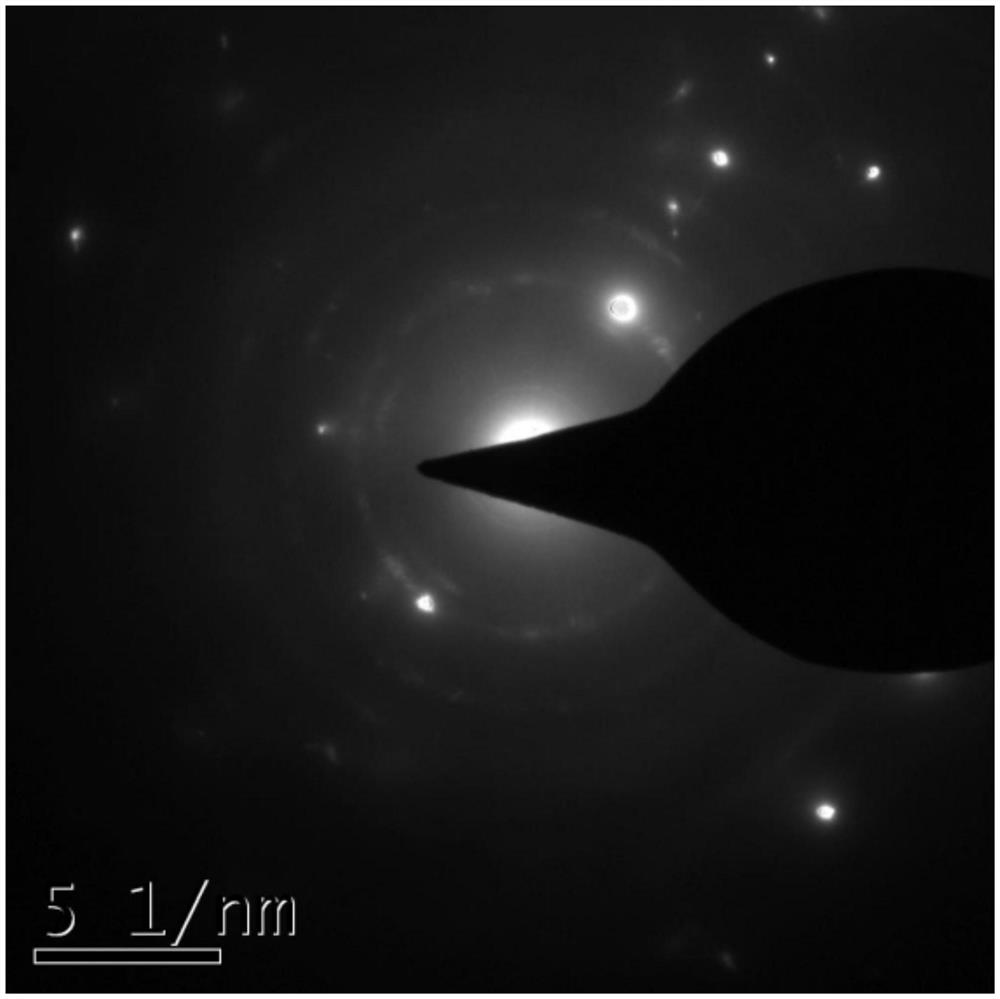

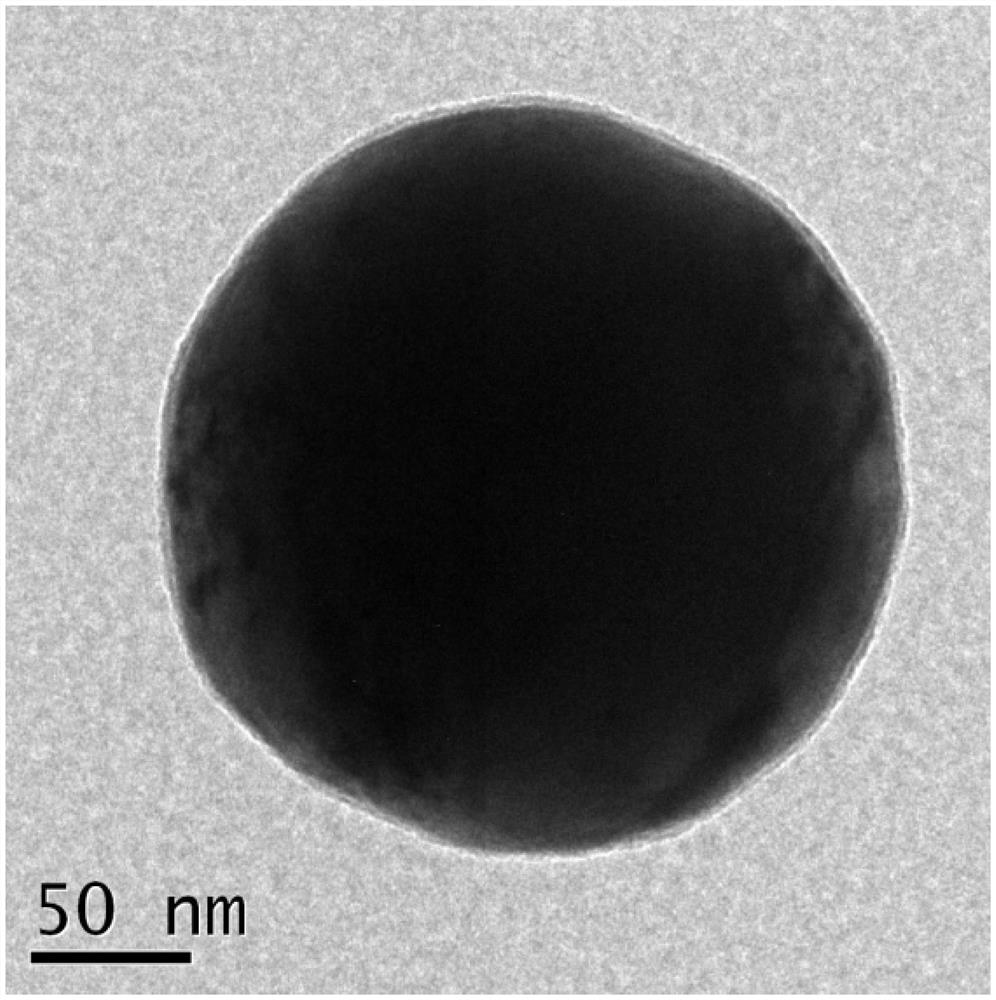

[0034] A nano-nickel powder with a core-shell structure, comprising spherical nickel beads and a protective layer coated on the outer surface of the spherical nickel beads with passivation and anti-agglomeration functions, the spherical nickel beads have a crystal structure, and the spherical nickel beads The diameter of the nickel ball is 10nm-600nm, the thickness of the protective layer is 0.5nm-6nm, and the protective layer is a nickel-sulfur-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com