Easy-care treatment method of pure cotton products for clothing

A treatment method and technology for cotton products, which is applied in the treatment of textile materials, fiber treatment, spray/jet treatment of textile materials, etc., can solve the problems of many wrinkles and troubles, and achieve the advantages of increased air permeability, comprehensive coverage and protective properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

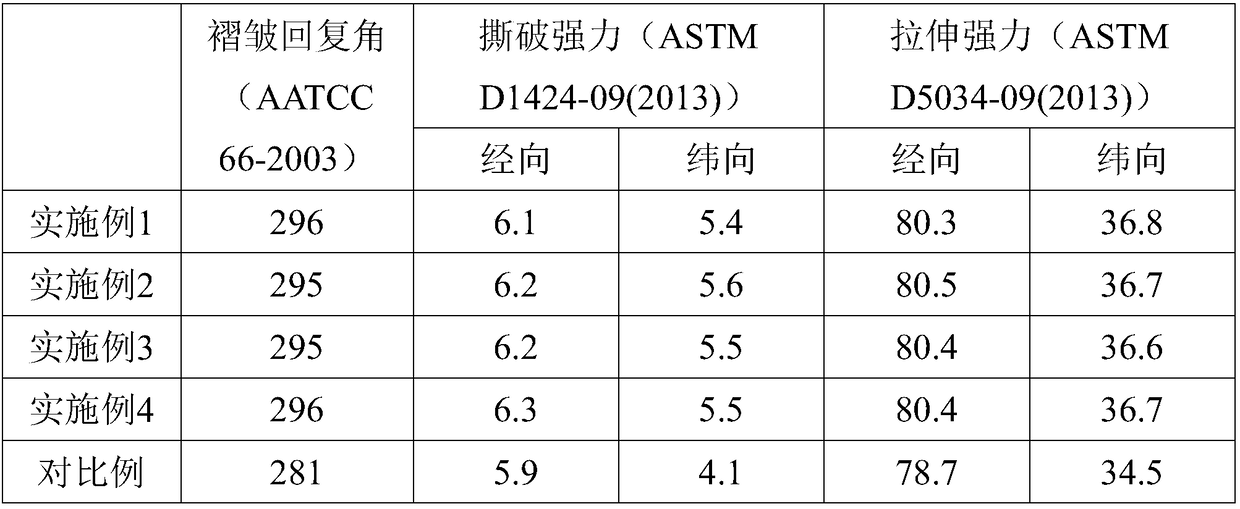

Examples

Embodiment 1

[0028] A non-ironing treatment method for pure cotton products for clothing, comprising the following steps:

[0029] (1) Soak the pure cotton products with water until they are not dripping, spread them flat on a flat work surface, flatten the pure cotton products with a flat plate, and then hang them upright;

[0030] (2) Add the non-ironing treatment agent to 35 times of water and mix evenly, atomize and spray it on the erected pure cotton products with an atomizer, and the consumption of the non-ironing treatment agent is 20% of the weight of the pure cotton products;

[0031] (3) Bake the pure cotton products sprayed with the non-ironing treatment agent at 130° C. for 10 minutes with a baking machine;

[0032] (4) Put the baked pure cotton product into steam at 130°C and 0.27Mpa saturated vapor pressure for 55 minutes, spread it on a flat work surface after cooling, and heat and dry it with high infrared radiation.

[0033] The non-iron treatment agent is composed of the...

Embodiment 2

[0035] A non-ironing treatment method for pure cotton products for clothing, comprising the following steps:

[0036] (1) Soak the pure cotton products with water until they are not dripping, spread them flat on a flat work surface, flatten the pure cotton products with a flat plate, and then hang them upright;

[0037] (2) Add the non-ironing treatment agent to 35 times of water and mix evenly, atomize and spray it on the erected pure cotton products with an atomizer, and the consumption of the non-ironing treatment agent is 15% of the weight of the pure cotton products;

[0038] (3) Bake the pure cotton products sprayed with the non-ironing treatment agent at 130° C. for 11 minutes with a baking machine;

[0039] (4) Put the baked pure cotton products into steam at 130°C and 0.27Mpa saturated vapor pressure for 50 minutes, spread them on a flat work surface after cooling, and heat and dry them with high infrared radiation.

[0040] The non-iron treatment agent is composed o...

Embodiment 3

[0045] A non-ironing treatment method for pure cotton products for clothing, comprising the following steps:

[0046] (1) Soak the pure cotton products with water until they are not dripping, spread them flat on a flat work surface, flatten the pure cotton products with a flat plate, and then hang them upright;

[0047] (2) Add the non-ironing treatment agent to 40 times of water and mix evenly, atomize and spray it on the erected pure cotton products with an atomizer, and the consumption of the non-ironing treatment agent is 25% of the weight of the pure cotton products;

[0048] (3) Bake the pure cotton products sprayed with the non-ironing treatment agent at 150° C. for 12 minutes with a baking machine;

[0049] (4) Put the baked pure cotton products into steam at 130°C and 0.27Mpa saturated vapor pressure for 60 minutes, spread them on a flat work surface after cooling, and heat and dry them with high infrared radiation.

[0050] The non-iron treatment agent is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com