Given-force engineering method for multisection expanded head discrete material pile composite foundation

A technique of granular material and composite foundation, which is applied in the field of soft foundation treatment and pile foundation force-giving method, can solve the problems of limited bearing capacity characteristic value of composite foundation, and achieve sustainable development, high bearing capacity characteristic value, The effect of strong ability to adapt to engineering needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

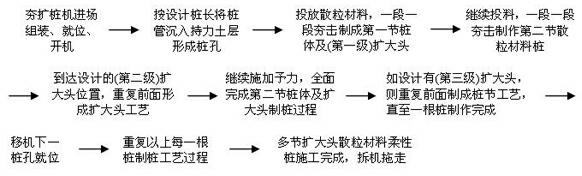

[0097] Therefore, the implementation of this construction method has two construction processes:

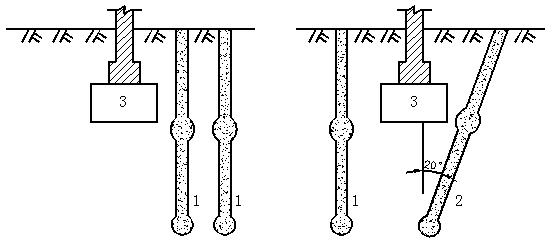

[0098] 1) Construction process characteristics of flexible piles with rammed and expanded multi-section enlarged heads and granular materials: see image 3 ;

[0099] 2) Construction process characteristics of rigid piles with variable stiffness rammed and expanded belts: see Figure 4 .

[0100] (1) Carefully investigate the characteristics of the proposed site. It mainly includes the composition of soil layers, the uniformity of horizontal bedding, whether there is a soft bedding layer, the soil quality conditions of the main stress-bearing layer of the foundation, the change of groundwater level and corrosion, etc. For areas with hidden ditches, dark ponds or ancient river courses, it is necessary to find out the specific location, range size, depth change, and soil conditions of filling materials.

[0101] (2) Comprehensively analyze the characteristics of the proposed pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com