Freezing process water stopping device of pre-buried freezing pipe at opening of wall body of underground continuous wall

An underground diaphragm wall and water-stopping device technology, which is applied in the field of freezing-method water-stopping devices and freezing-method water-stopping devices with pre-buried frozen pipes, which can solve the problems of easy water leakage, difficulty in ensuring tight fit, and abnormal soil excavation Complete and other issues to achieve the effect of increased reliability and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

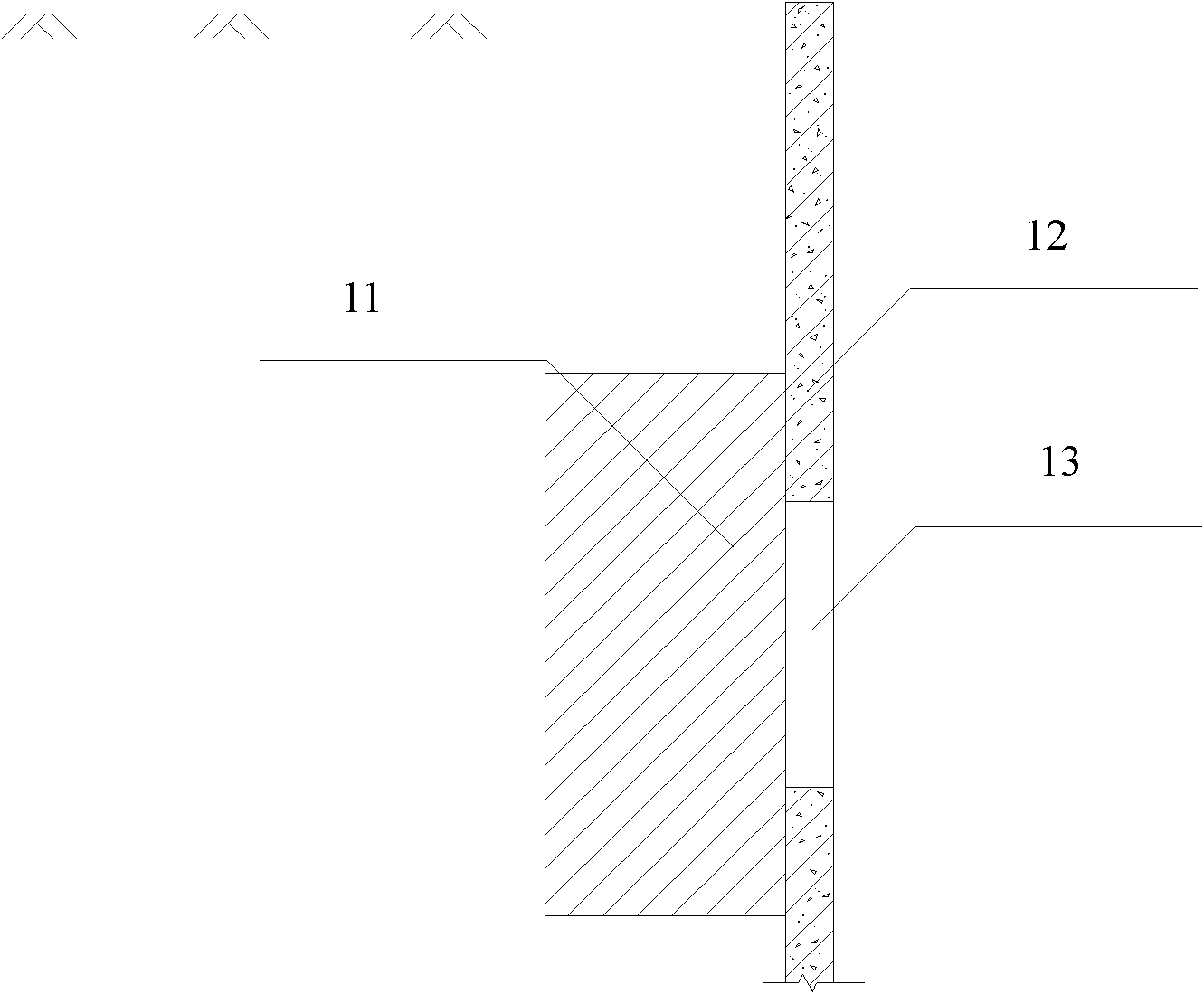

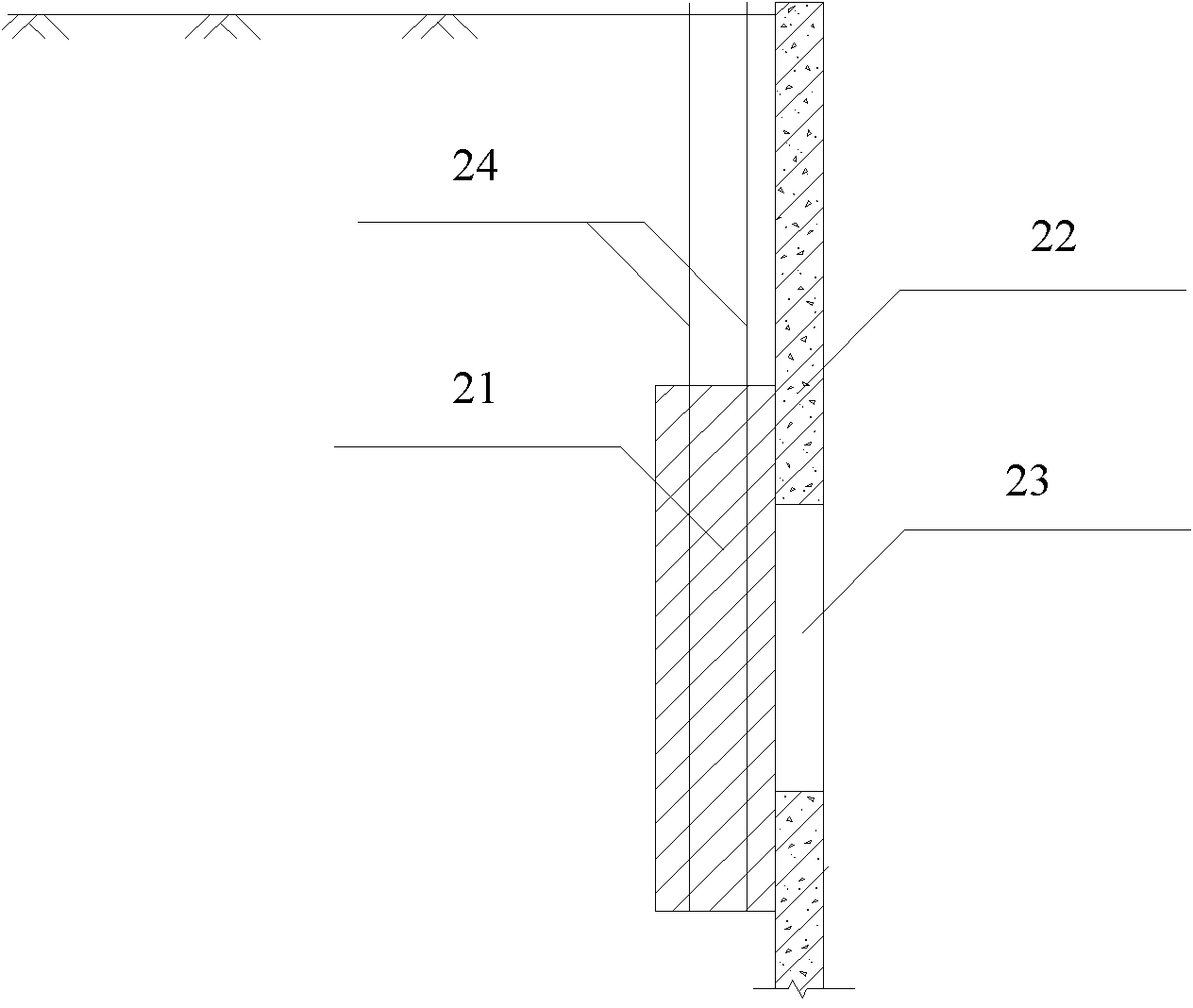

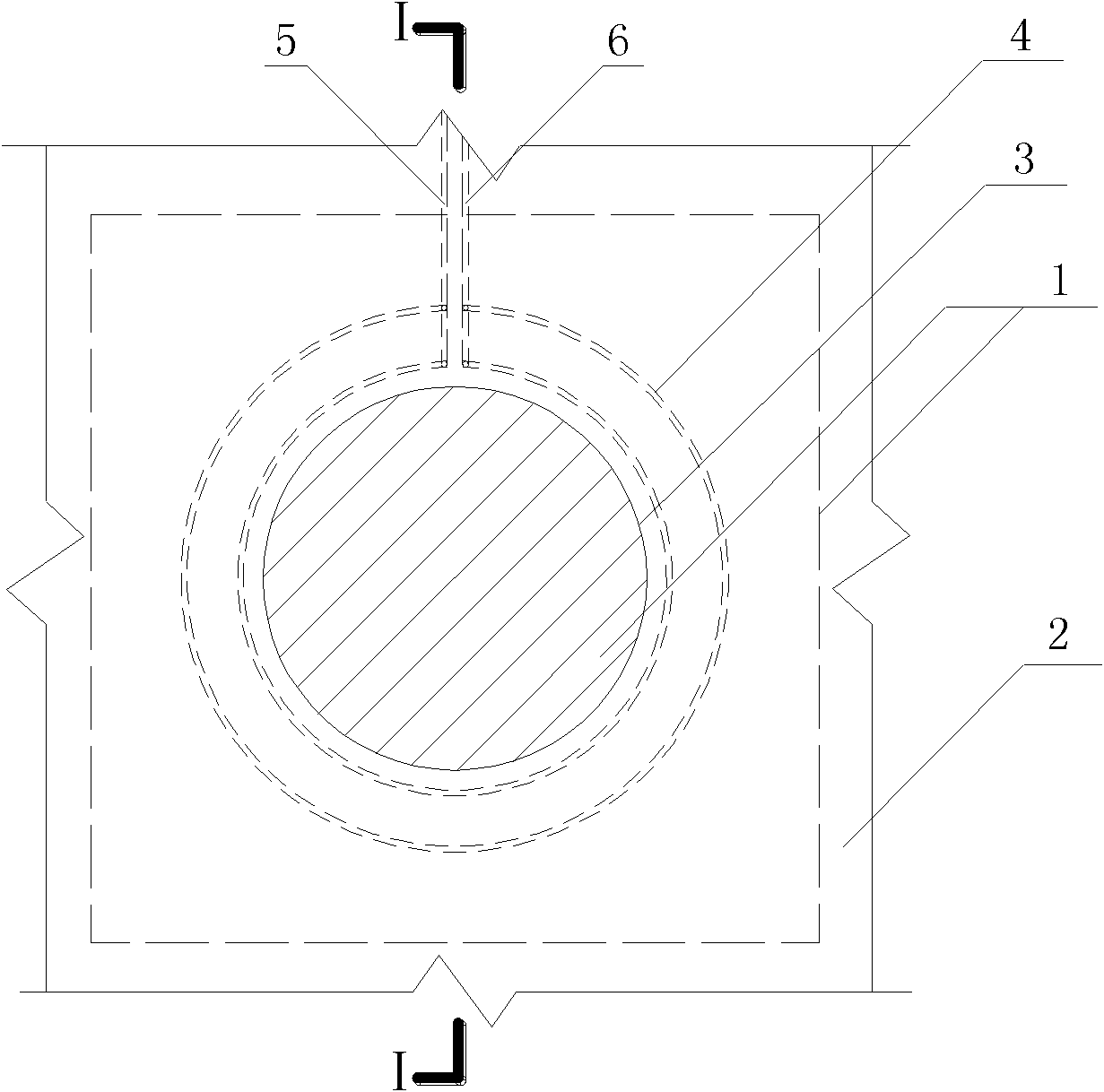

[0026] Such as Figure 3-Figure 6 As shown, the freezing method water stop device of the present invention comprises the freezing pipe 4 pre-buried in the underground diaphragm wall, the liquid supply pipe 5 pre-buried in the underground diaphragm wall and the liquid discharge pipe 6 pre-buried in the underground diaphragm wall . The shape of the pre-embedded freezing pipe 4 matches the shape of the edge of the wall to be removed, and the diameter of the freezing pipe is set to 40-60 mm. The freezing pipe 4 is an annular structure with a notch, one end of the notch is connected to the liquid supply pipe 5 , and the other end is connected to the liquid discharge pipe 6 . The diameters of the liquid supply pipe 5 and the liquid discharge pipe 6 are the same as those of the freezing pipe 4 . One or more rings of pre-embedded freezing pipes 4 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com