Automatic air discharge device for oil line of horizontal bar internal combustion engine

An internal combustion engine, automatic discharge technology, applied in the direction of machines/engines, liquid fuel feeders, charging systems, etc., can solve the problems of inability to start, waste energy, pollute the environment, etc., to save manpower, reduce resource waste and environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

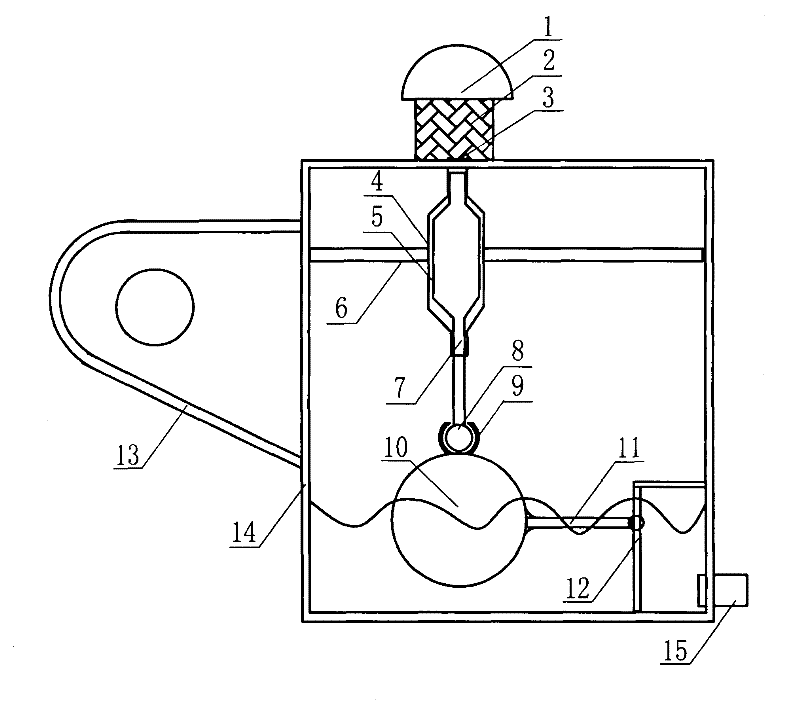

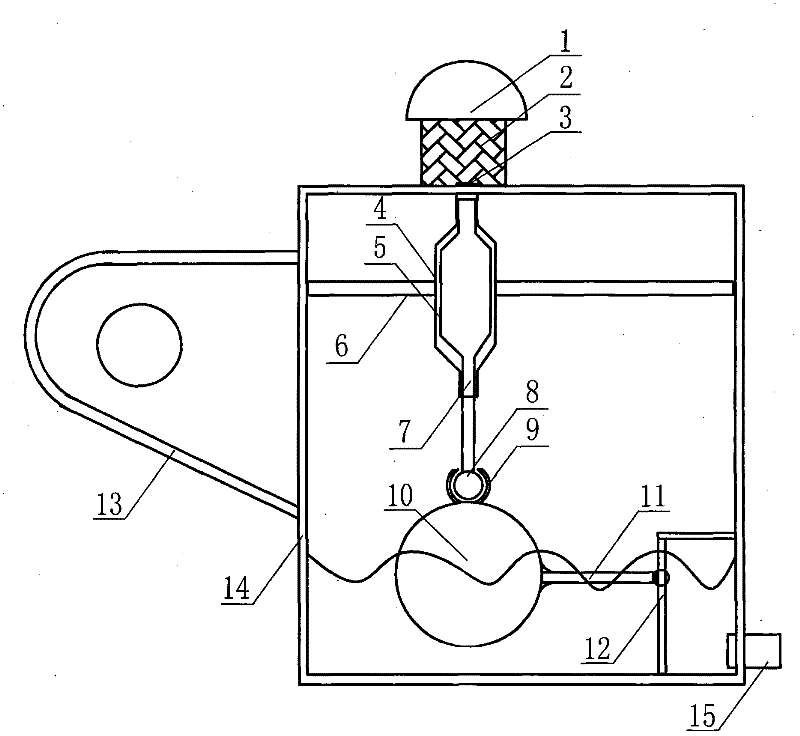

[0009] Such as figure 1 A kind of horizontal bar internal-combustion engine oil circuit automatic exhaust air device shown, comprises box body 14, floating ball device, exhaust gas device, is welded with box body fixing bracket 13 on box body 14, by box body fixing bracket 13 the whole box body Installed in the lower part of the internal combustion engine oil tank; the ball float device includes an oil float 10, a ball float stabilizer 11, a float support 12, and one end of the ball float stabilizer 11 is connected to the oil float 10, and the other end of the ball float stabilizer 11 One end is sleeved on the float bracket 12, and can slide along the float bracket 12, and the float bracket 12 is installed at the inner bottom of the box body 14; the exhaust gas device includes oil plug 5, oil plug 4, oil plug ejector rod 7. The oil plug 4 is installed in the box body 14 through the oil plug bracket 6. One end of the oil plug 4 is the air outlet 3, which is located outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com