Linear slide block and manufacturing method thereof

A manufacturing method and sliding block technology, which are applied in the direction of manufacturing tools, linear motion bearings, bearings, etc., can solve the problems such as the inability to effectively provide a cooling mechanism and the inability to increase the wear speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

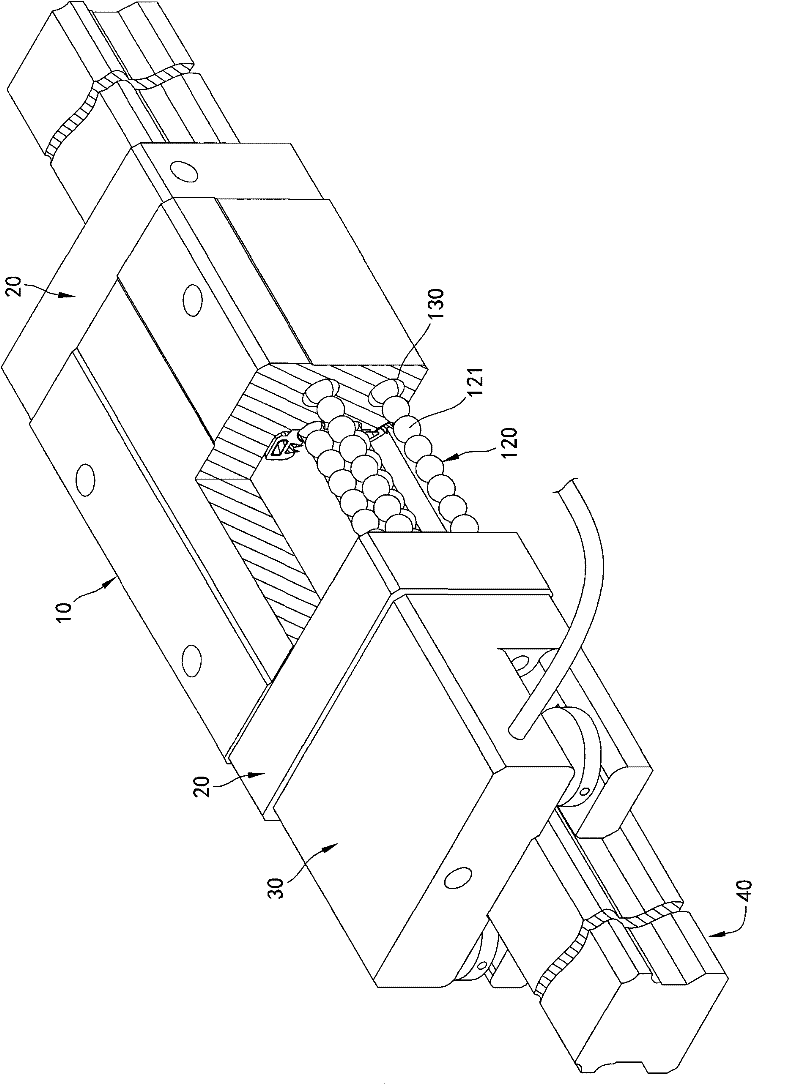

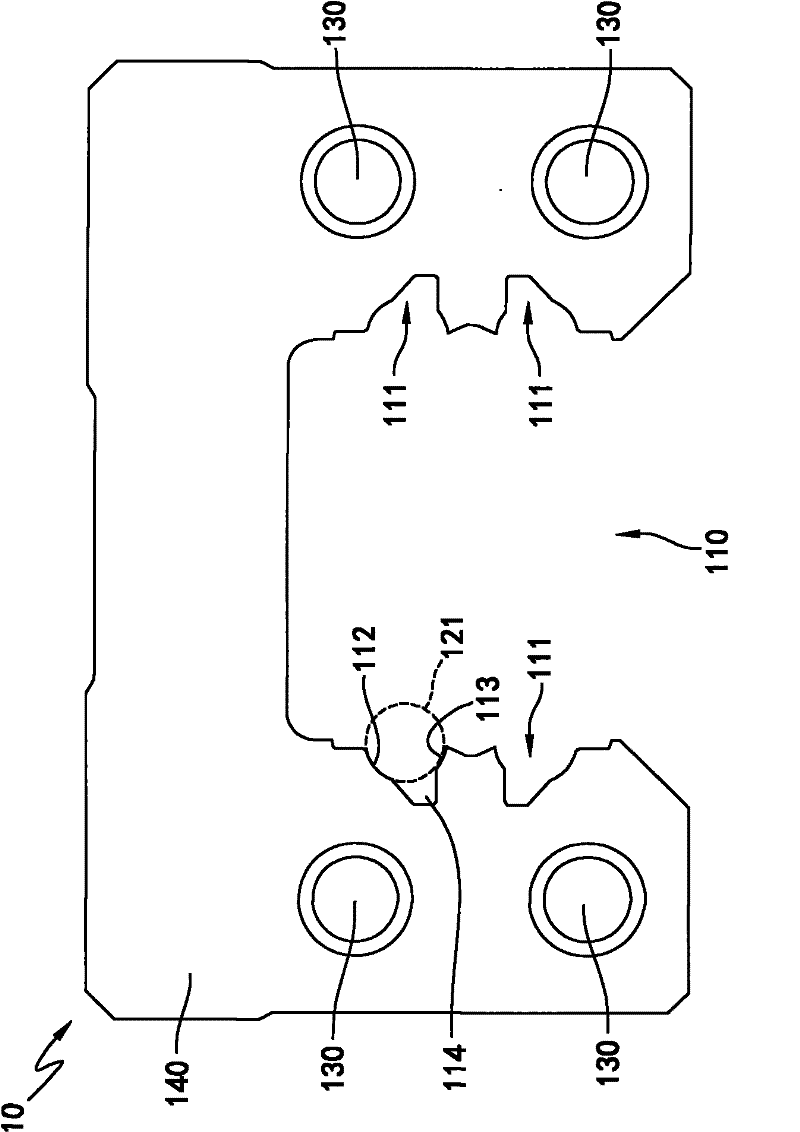

[0049] see figure 1 , Figure 2A with Figure 2B , the opposite side surfaces of the linear slider 10 disclosed in the first embodiment of the present invention are respectively provided with an end cover 20, and one of the end covers 20 is combined with the oil supply assembly 30, and together with the end cover 20 and the oil supply assembly 30 sets fit on the linear slide rail 40 and can move back and forth relative to the linear slide rail 40 . At the same time, during the reciprocating movement, the oil supply assembly 30 provides an oil on the linear slider 10 , so that there is a lubricating effect between the linear slider 10 and the linear slide rail 40 .

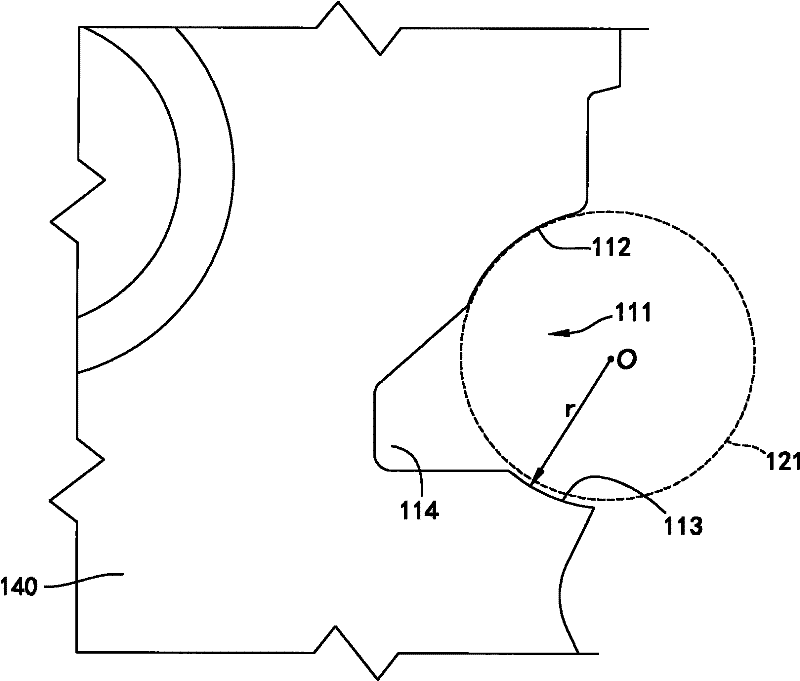

[0050] The linear slider 10 has a chute 110 and a ball circulation system 120, and the linear slider 10 is provided with a plurality of return channels 130, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap