Garbage burning device

A garbage combustion and combustion chamber technology, which is applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of heavy workload, insufficient garbage combustion, long burning time, etc., to achieve enhanced turning effect, sufficient garbage combustion, and incineration fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

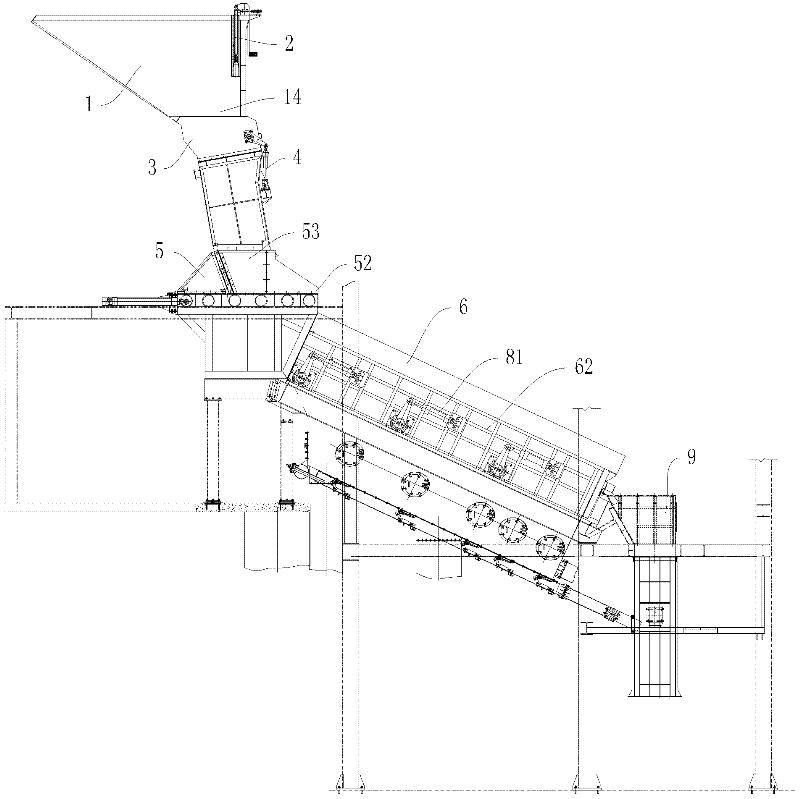

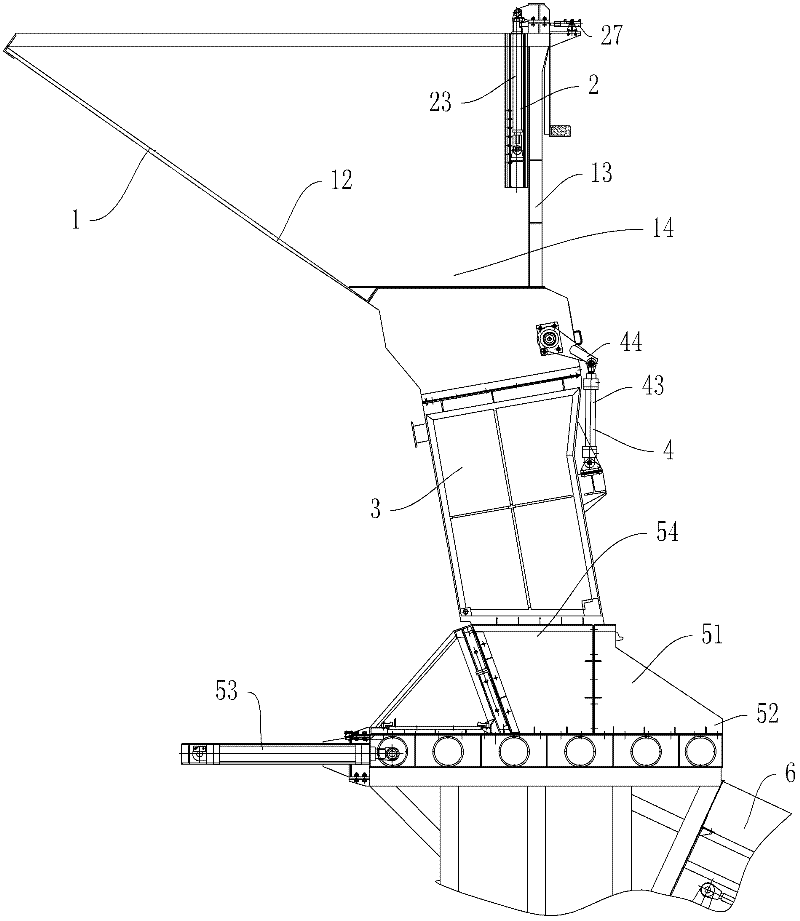

[0048] see figure 1 The garbage burning device shown includes a hopper 1, a bridge breaking device 2, a throat 3, a valve device 4, a garbage conveying device 5, a combustion chamber 6, and a slag well 9.

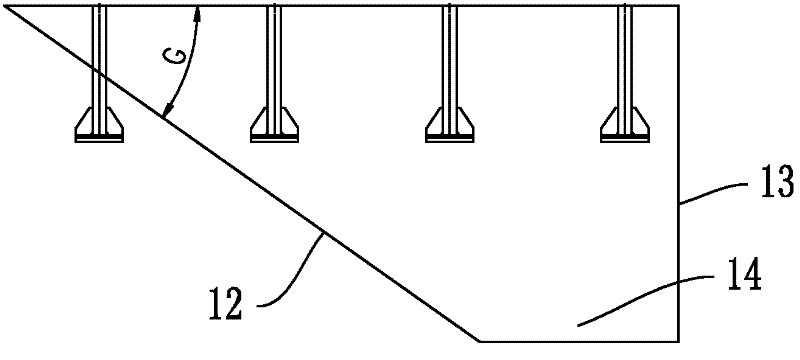

[0049] The main body of the hopper 1 is a quadrangular pyramid composed of four hopper plates 11, one of which is a hopper plate 12 forming an included angle of G=35° with the horizontal plane. The hopper plate 13 opposite to the hopper plate 12 is perpendicular to the horizontal plane.

[0050] The garbage delivery device 5 includes a garbage delivery bin 51 carrying garbage and a push pedal that moves to the outlet of the garbage delivery bin to move relative to the inside of the garbage delivery bin; the push pedal and the push pedal oil cylinder 53 that drives it to move Link to each other, the two ends of push pedal oil cylinder 53 link to each other with push pedal and rubbish delivery bin respectively. Push plate, push plate oil cylinder etc. belong to prior art, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com