Method for detecting fatigue damage of blade of horizontal axis wind turbine

A wind turbine blade and fatigue detection technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as failure to obtain the fatigue performance of blades, and meet the low requirements for testing equipment and the environment. Conditional requirements, the effect of reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0038] In this embodiment, taking the current mainstream MW wind turbine blades as an example, the following steps are used for detection and result correction:

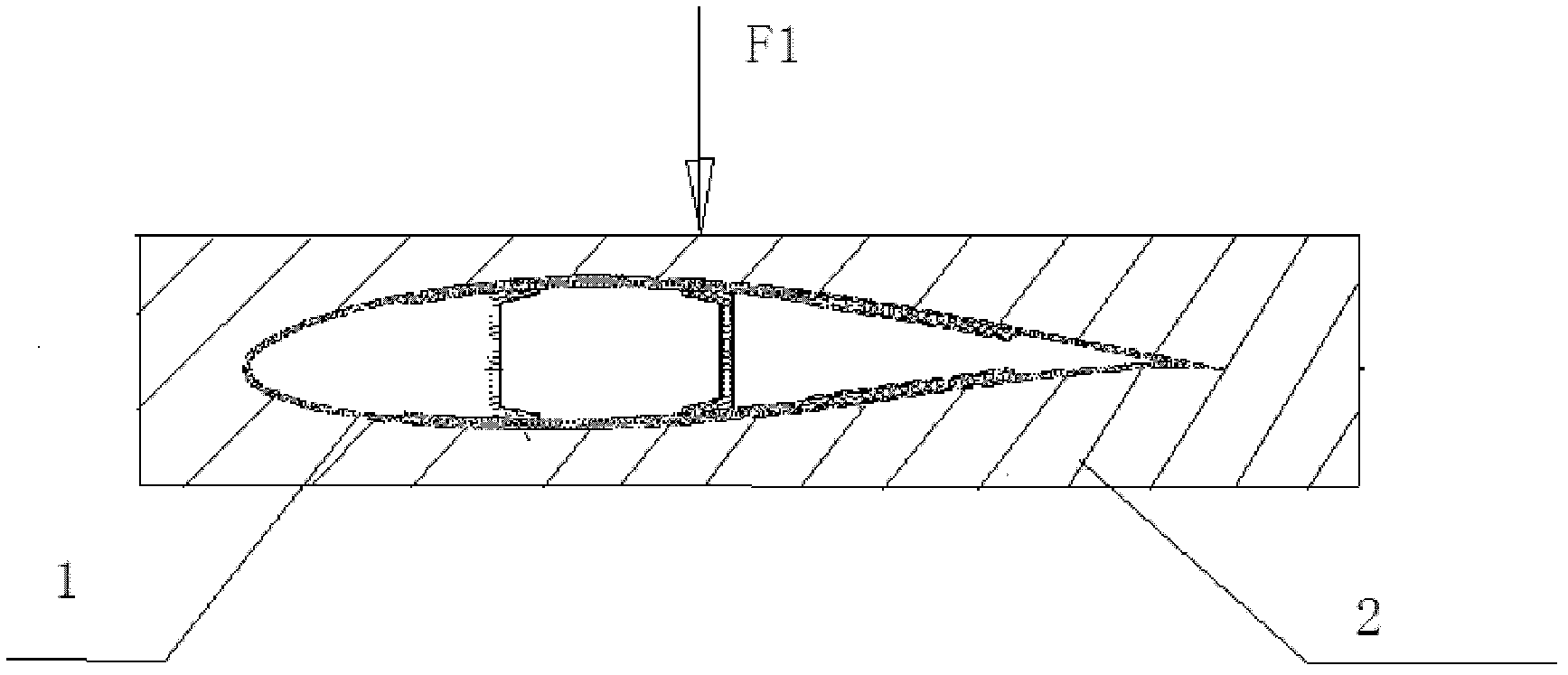

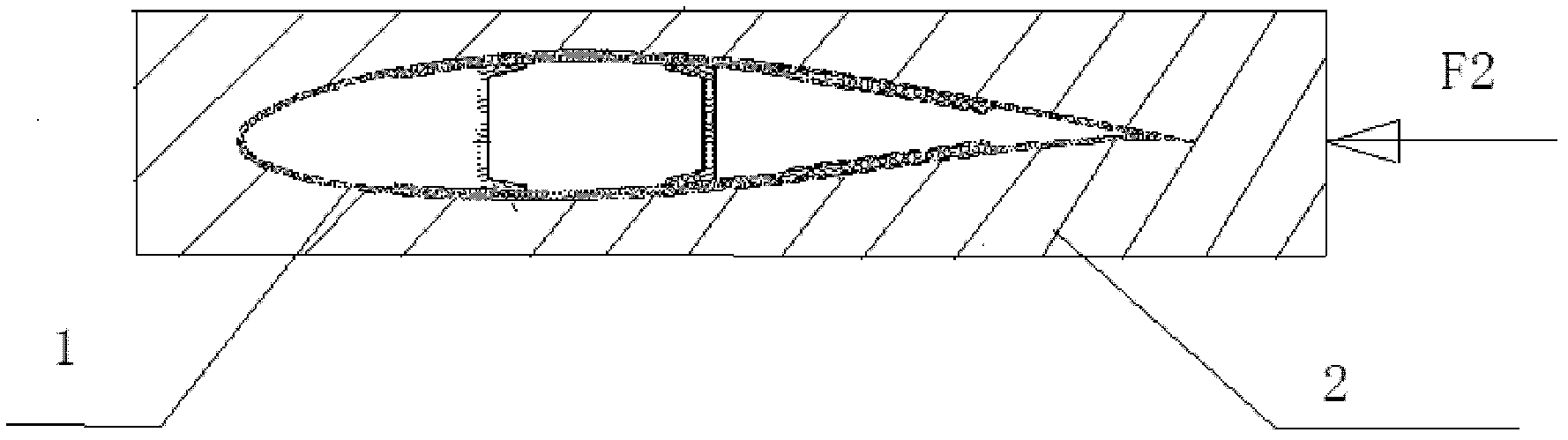

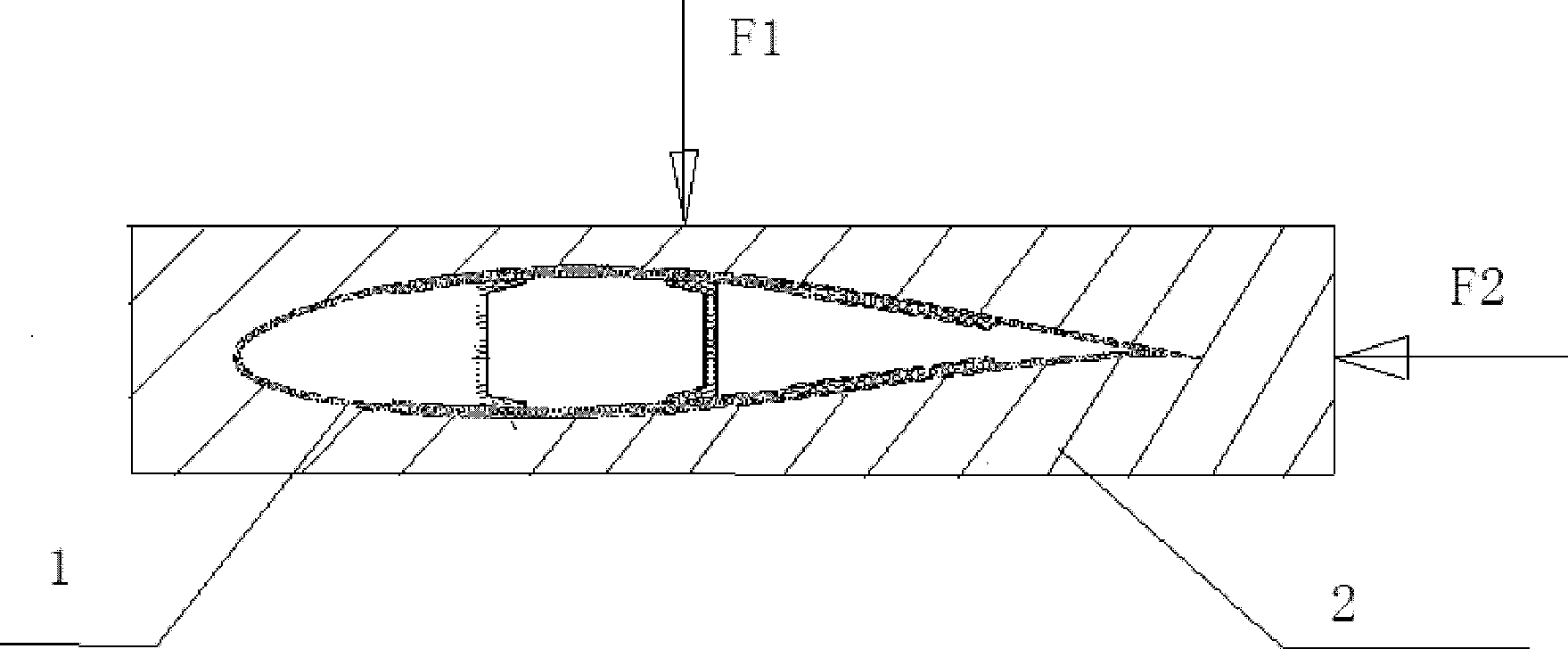

[0039] 1) if figure 1 , figure 2 As shown, using the existing general blade uniaxial fatigue detection method, the fatigue loads (F1) and (F2) are applied to the blade flapping and shimmy directions respectively, and the fatigue detection is carried out to obtain the fatigue performance in the two cases;

[0040] 2) Using the linear damage accumulation theory, the results obtained in 1) are processed to obtain the fatigue performance of the blade under the sequential action of the above two loads;

[0041] 3) Using the numerical simulation method to evaluate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com