Artificial core, manufacturing method and instrument of artificial core

A technology of artificial core and manufacturing method, applied in the field of artificial core, to achieve the effect of eliminating different core pore structures and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

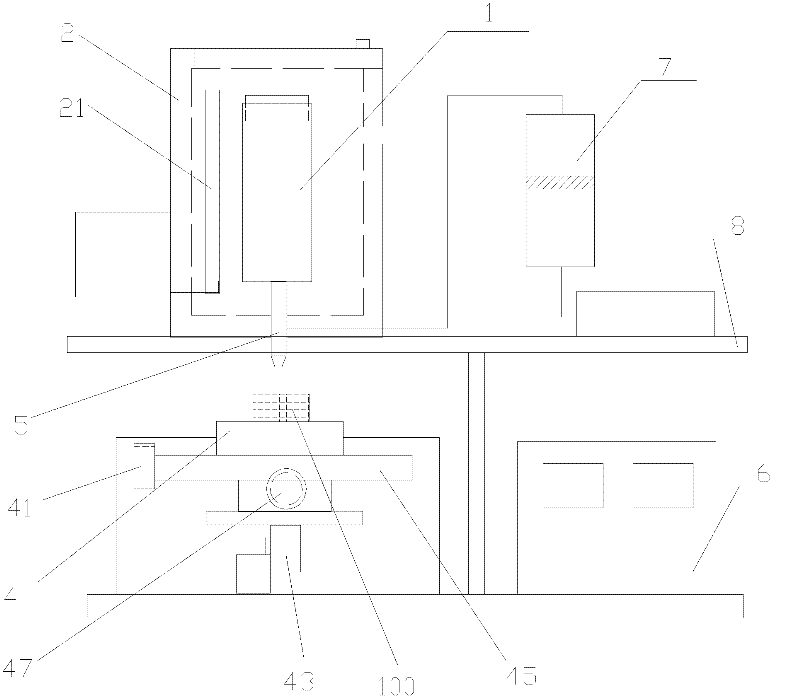

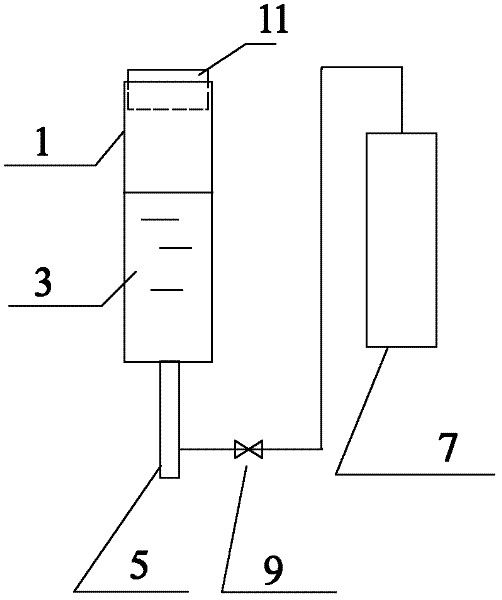

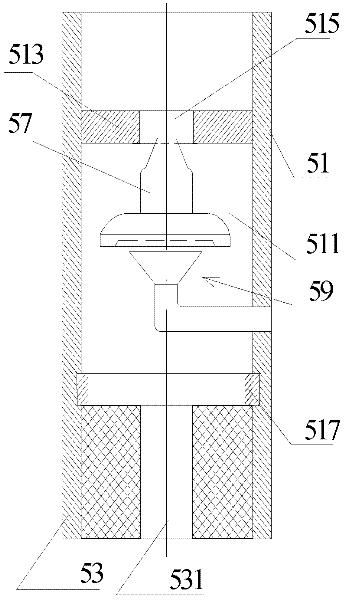

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0041] The present invention proposes a manufacturing method of an artificial rock core, which is also called a three-dimensional printing method of a high-melting point medium. The manufacturing method of the artificial rock core includes, for example: steps A, B, C, and D.

[0042] A. Select the medium as the material for making the artificial core, usually choose a medium close to the material of the natural core, for example, the medium is glass particles or sodium silicate powder or quartz, so that the artificial core obtained is closer to the natural core , the present invention selects described medium as glass particle or sodium silicate powder, and its fusing point is about 1300 degrees, relatively speaking, fusing point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com