Surface defect detection system for tiny circular or circular ring-shaped parts

A defect detection and ring-shaped technology, which is applied in the direction of optical testing for defects/defects, can solve the problems of low detection efficiency, difficult control, and difficult clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

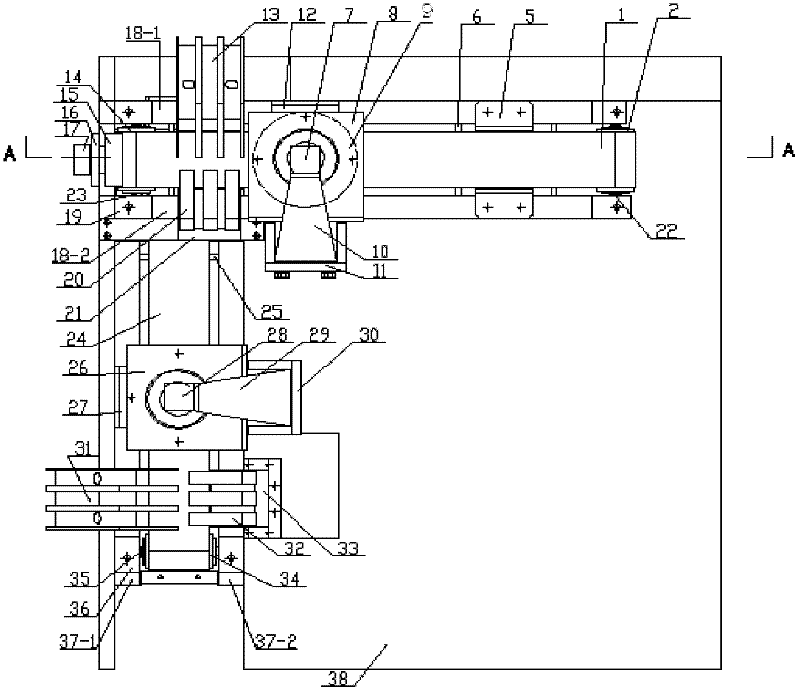

[0063] Embodiment 1 The present invention provides a system for detecting surface defects of tiny round or annular parts. The system can realize double-sided detection of tiny round or ring-shaped parts surface defects in the process of assembly line operation. The tiny round or annular parts refer to parts with a diameter within the range of 8-12mm.

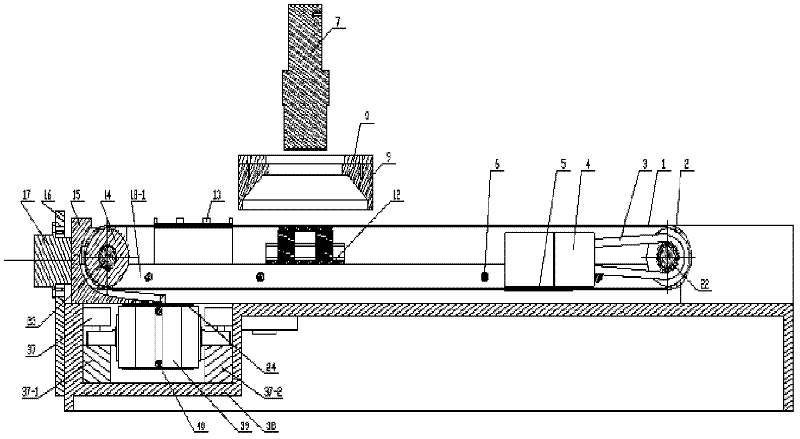

[0064] Such as figure 1 , 2 As shown, the surface defect detection system of a tiny round or annular part provided by the present invention includes a first transportation unit, a first optical detection unit, an automatic turning unit, a first automatic separation and recovery unit, a second transportation unit, and a second transportation unit. unit, the second optical detection unit, the second automatic separation and recovery unit, the control unit and the base 38;

[0065] (1) if Figure 5 , 6 As shown, the first transport unit includes a frame, a driving pulley device, a driven pulley device, a vibration damping dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com