Optical fiber composite insulator

A fiber composite and insulator technology, applied in the direction of lead-in/through-type insulators, fiber mechanical structures, etc., can solve the problems of easy fiber breakage, lower insulator pass rate, and increased fiber loss, and achieve the effect of improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to further illustrate the present invention, a preferred embodiment is given in detail as follows in conjunction with the accompanying drawings:

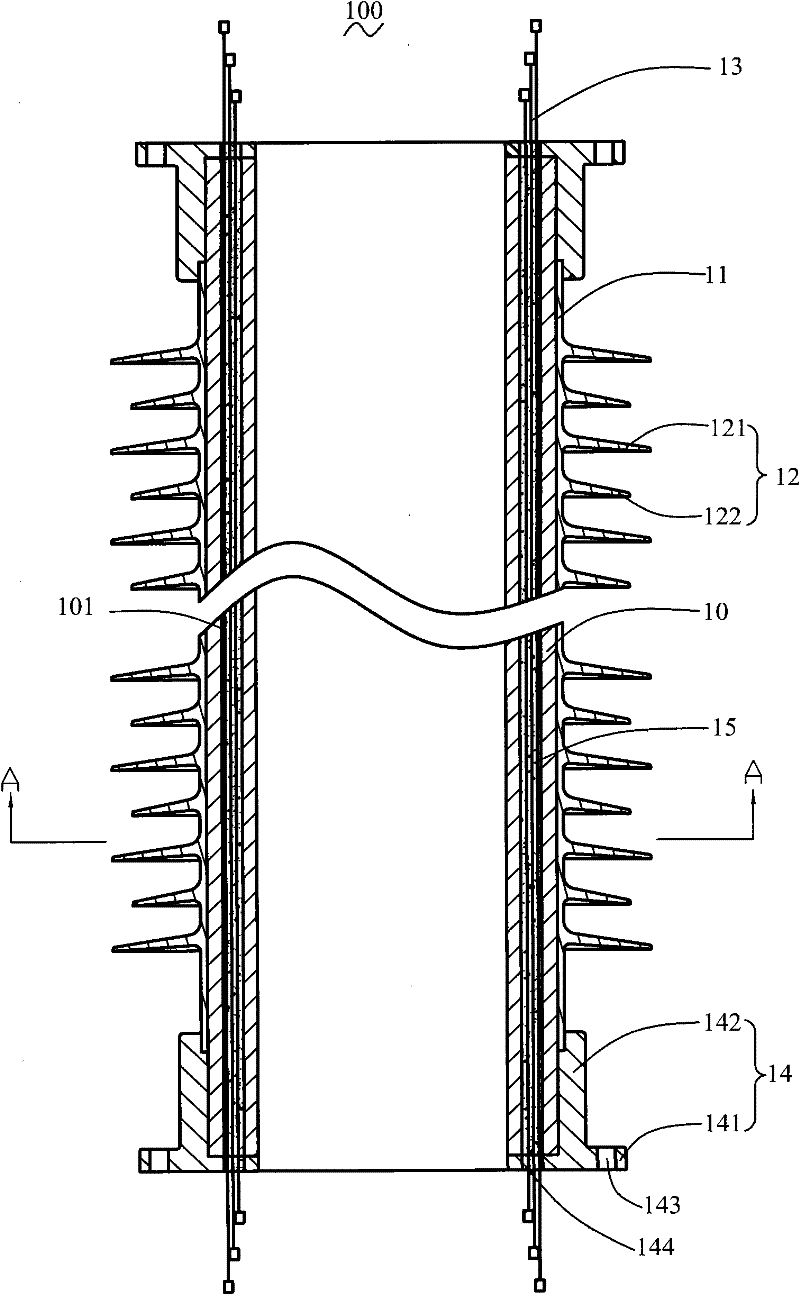

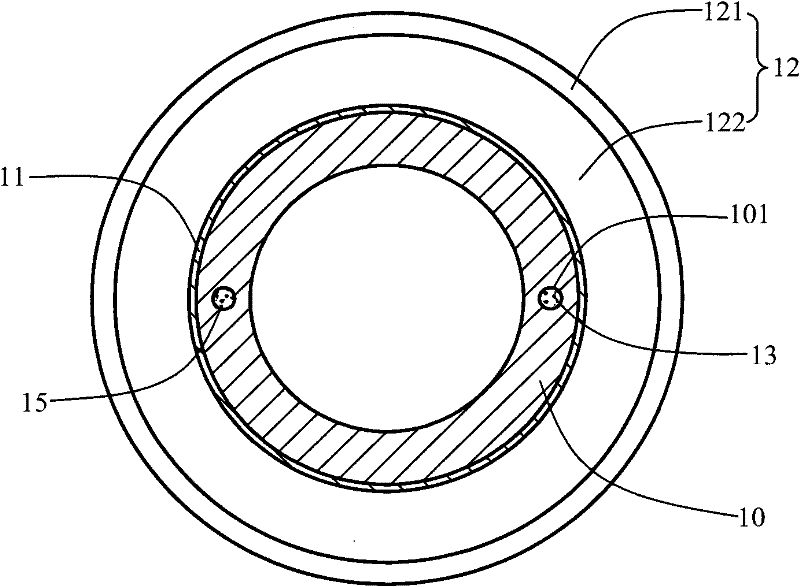

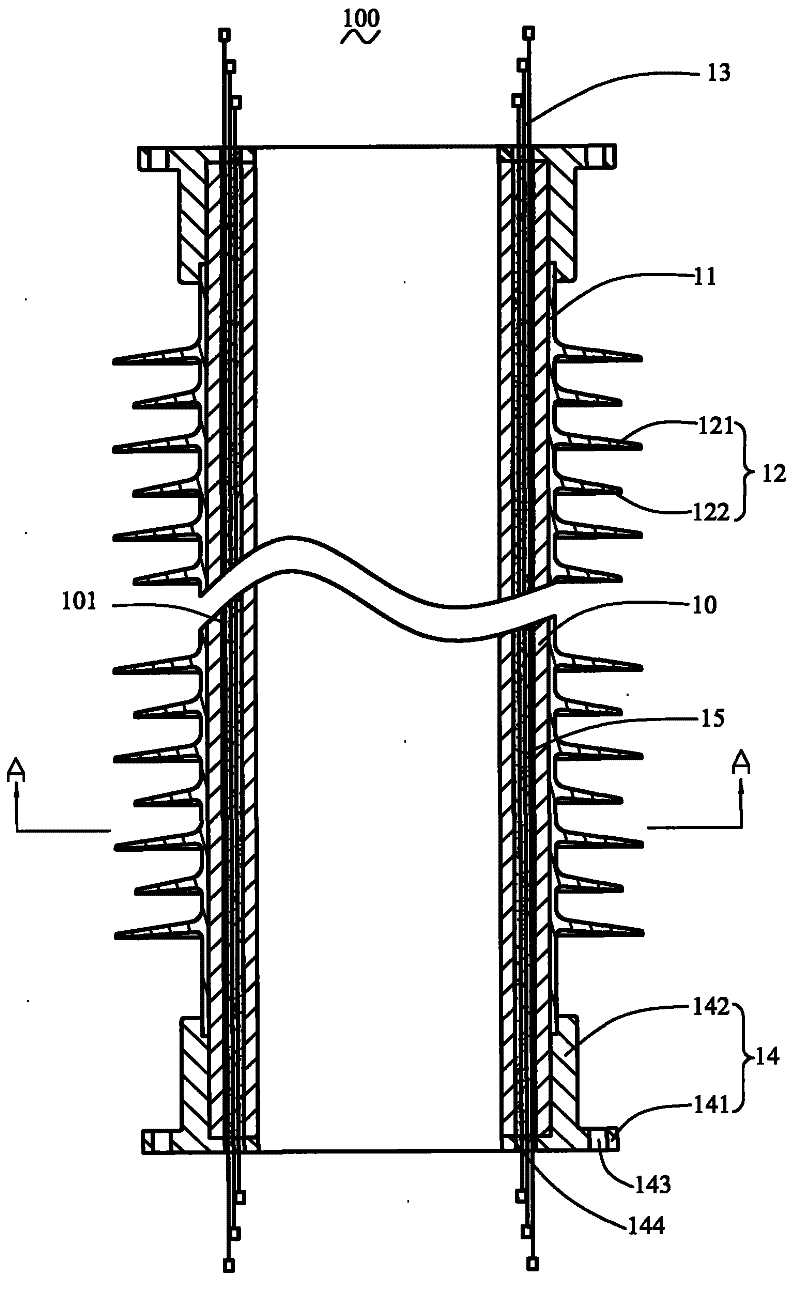

[0009] see figure 1 and figure 2 , which is a schematic structural diagram of an optical fiber composite insulator 100 provided by the present invention. The fiber optic composite insulator 100 includes a support body 10, a sheath 11 covering the outside of the support body 10, at least one shed 12 arranged on the sheath 11, at least one shed 12 arranged on the support body 10 The optical fiber 13 in the support body 10, at least one flange 14 arranged at one end of the support body 10, and the fixing glue 15 for fixing the optical fiber 13.

[0010] The support body 10 can be a solid insulator or a hollow insulating tube. When the support body 10 is a solid insulator, the optical fiber composite insulator 100 is a pillar composite insulator for supporting wires and preventing current from returning to ground. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com