Coolant circuit

A main cooling circuit, coolant technology, applied in the control of coolant flow, liquid cooling, engine cooling, etc., can solve problems such as limitation, difficulty in reaching engine operating temperature, and circuit control deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

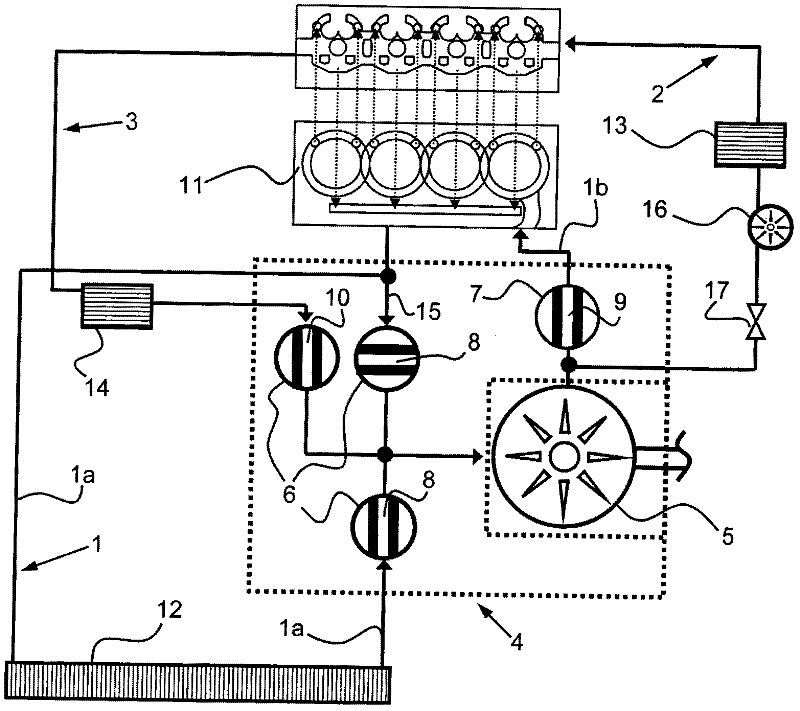

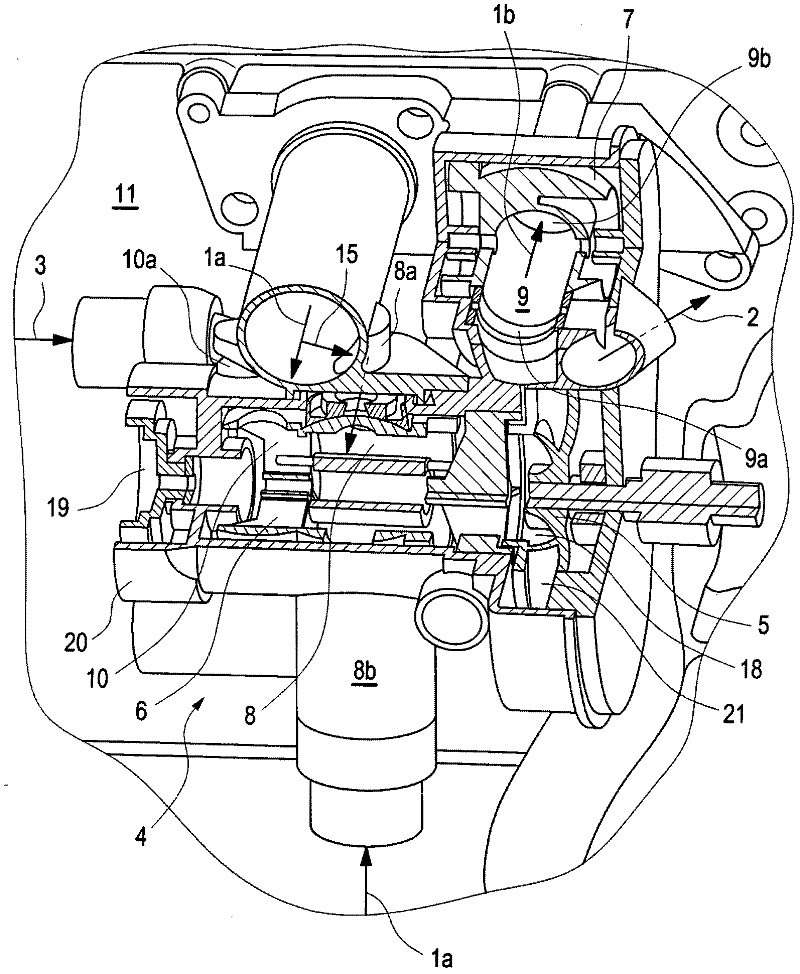

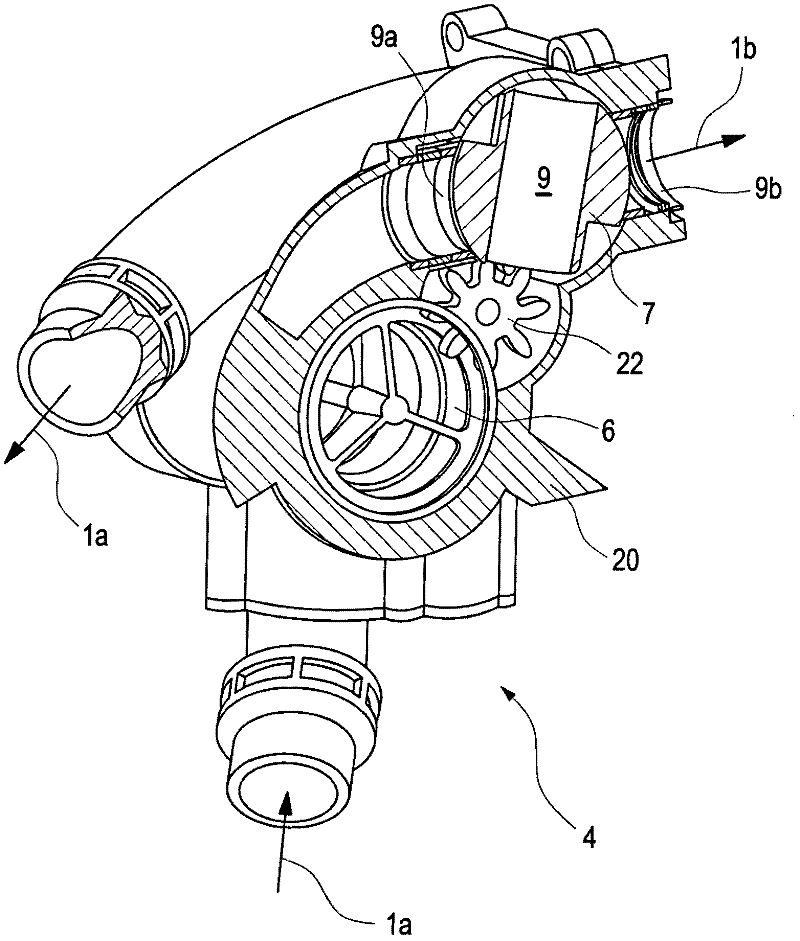

[0030] according to figure 1 , the coolant circuit for the engine 11 has a main cooling circuit 1 , a heating circuit 2 , an oil cooler circuit 3 and a rotary regulator 4 for controlling the coolant flow into each sub-circuit. The rotary regulator 4 comprises a rotary slide valve housing together with a rotatably mounted first rotary slide valve 6 and a second rotary slide valve 7 which have a rotary slide valve through-opening 8, 9 and 10. The rotary slide valve housing has in its wall a plurality of ports through which coolant can flow, which ports are at least partially connected to the rotary slide valve through-openings 8, 9 and and / or 10 intersect to form different flow paths for the connected partial circuits 1 , 2 and 3 . A coolant supply pump 5 is arranged on the rotary regulator 4 , which sucks in coolant from the first rotary slide valve 6 and feeds it into the second rotary slide valve 7 . The engine 11 essentially consists of a cylinder block and a cylinder hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com