Special drilling equipment

A technology of drilling equipment and power head, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problems of high processing precision, poor precision, high efficiency, etc., to improve quality and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

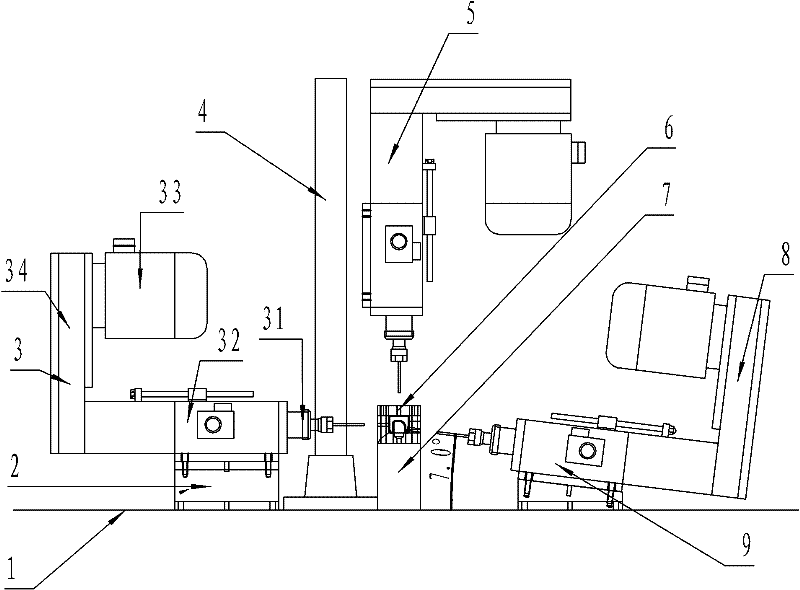

[0023] Embodiment 1, a kind of special-purpose drilling equipment is characterized in that: comprise the drilling equipment installed on the frame 1, feeding device, workpiece clamping device, electrical control device,

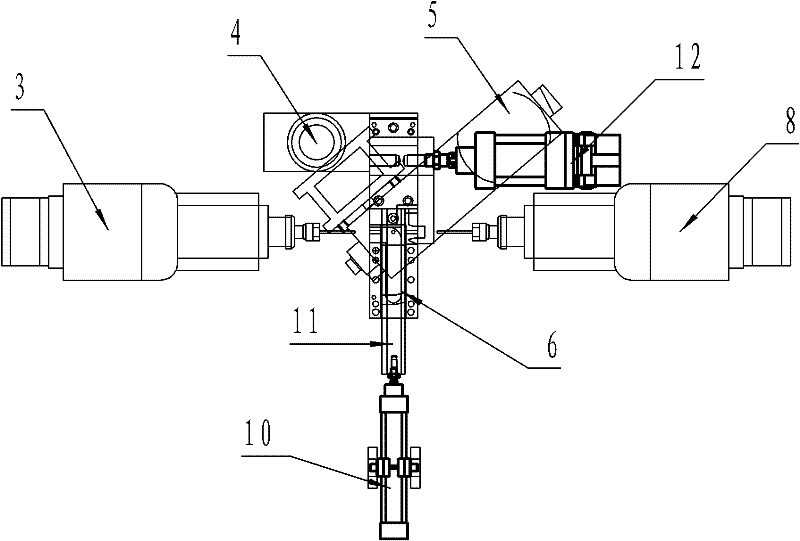

[0024] The drilling equipment includes a horizontal power head 3 installed on the horizontal base 2 of the machine head, a vertical power head 5 installed on the vertical adjustment mechanism 4, and an inclined direction power head 8 installed on the inclined base 9 of the machine head;

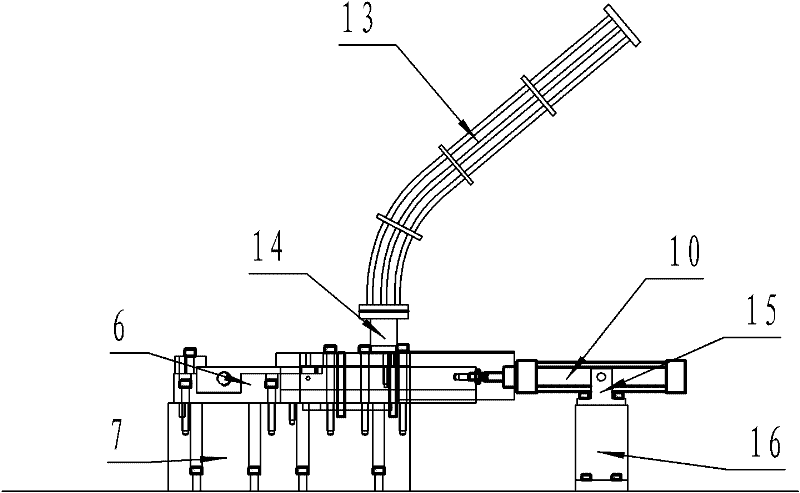

[0025] The feeding device includes a feeding curved groove 13 and a feeding straight groove 14 connected thereto,

[0026] The workpiece clamping device includes a fixture 6 installed on the fixture support seat 7, a small cylinder 10 for pushing the pusher block 11 and a large cylinder 12 for pushing and clamping the pusher plate, and the small cylinder is installed through the small cylinder bracket 15 On the small cylinder base 16, the large cylinder is installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com