Method for eliminating bending deformation of rolling mill-type heavy part

A heavy-duty parts, bending deformation technology, applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of uneven force, unqualified products, bending deformation, etc., to eliminate bending deformation, improve production efficiency, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

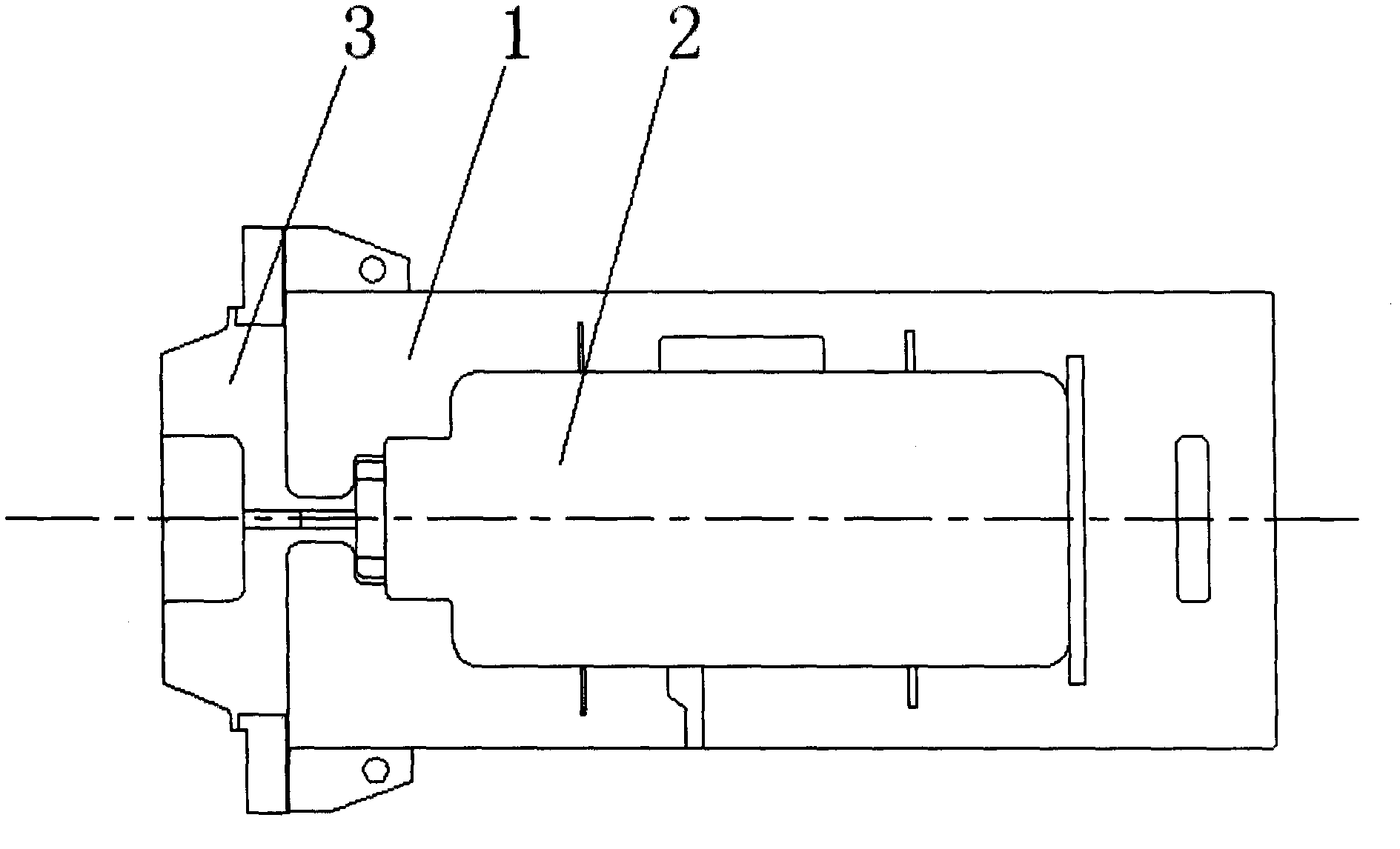

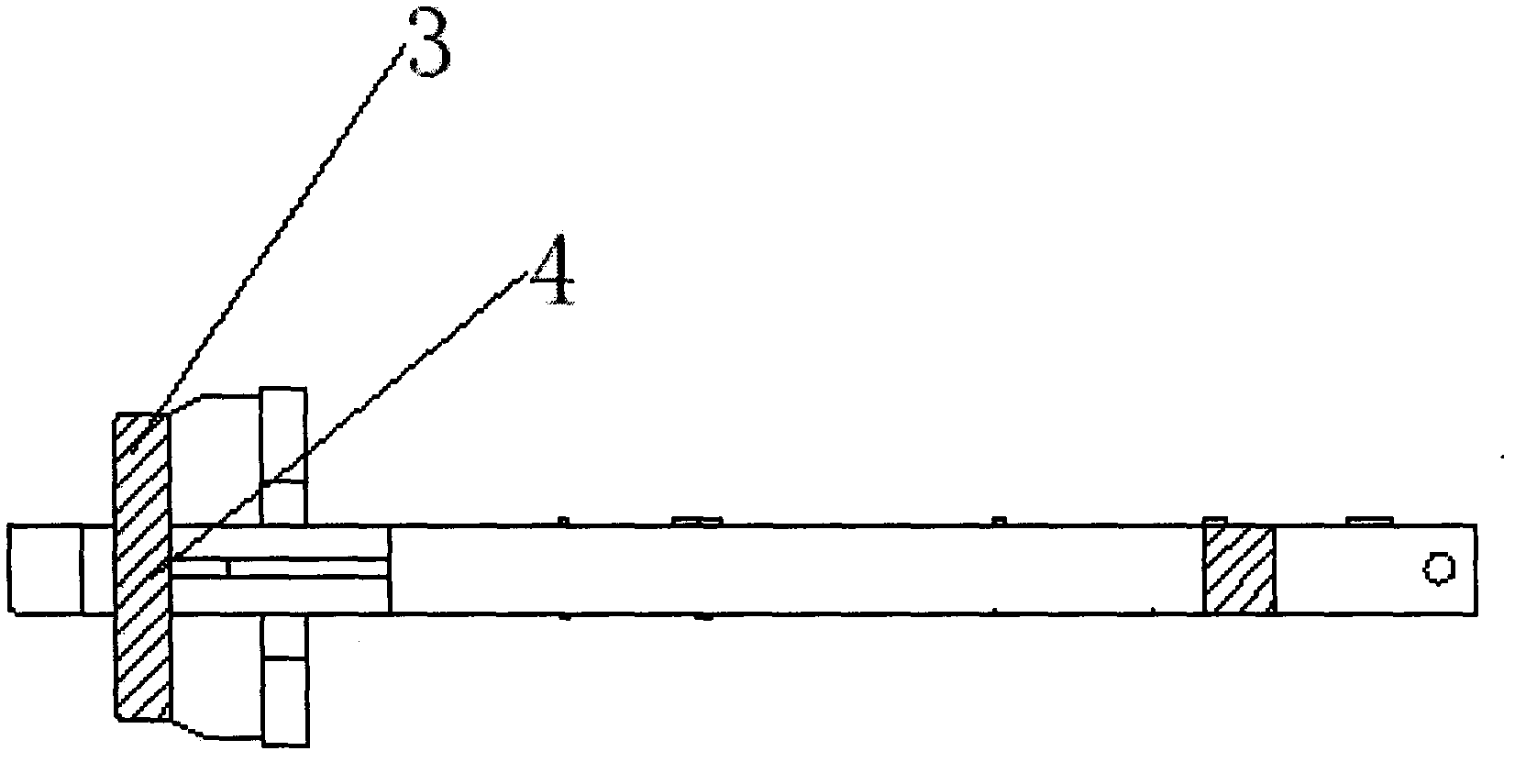

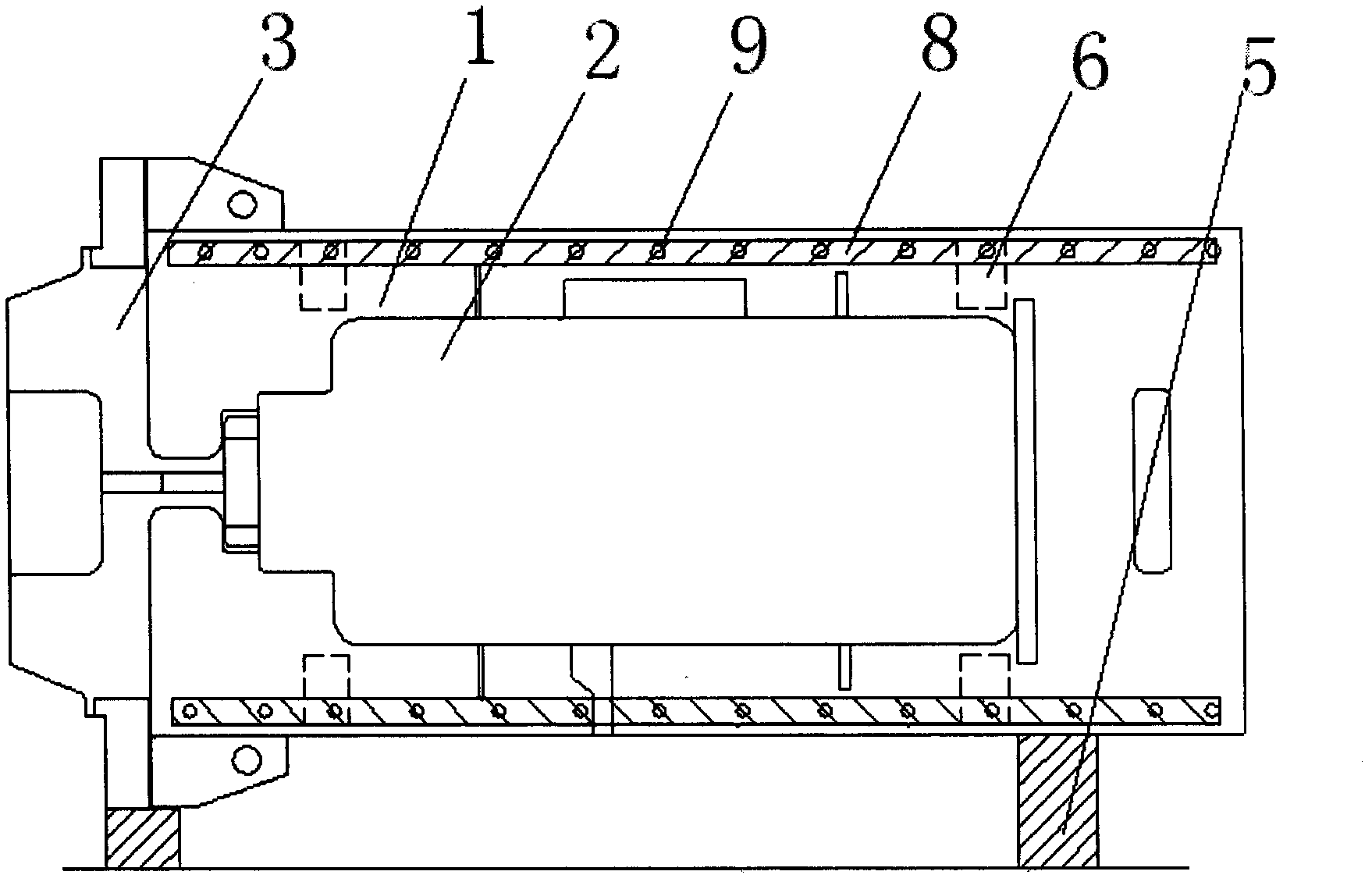

[0027] refer to Figure 1 to Figure 4 As shown, the method for eliminating bending deformation of heavy-duty rolling mill parts includes the following steps: Step 1, place the workpiece 1 flat on the workbench, and then process the side stand pad support when the workpiece 1 is laterally sideways on the side of the workpiece 1 Surface 4; step 2, place the workpiece 1 sideways on the workbench, place a side stand block 5 of the same height under the support surface 4 of the side stand block, and process the upper and lower sides of the workpiece 1 on the processing reference surface. Two measurement datum planes 8, and ensure that the flatness of the measurement datum planes 8 is less than 0.05mm, select a plurality of measurement datum points 9 on the measurement datum planes 8 at equal intervals P in the transverse direction, and the distance P should be selected according to the shape of the workpiece 1 In general, the spacing P is selected from 300mm to 500mm, and the flatn...

Embodiment 2

[0029] On the basis of Example 1, as a further optimization of the technical solution of the present invention, in step 1, when the workpiece 1 is placed flat on the workbench, it is necessary to first use the "three-point alignment method" to eliminate the distortion of the workpiece 1. "Three-point alignment method" is to set two reference pads and two auxiliary reference pads of the same height under the workpiece 1, and then use a jack as the third reference point to detect the two auxiliary pads by adjusting the height of the jack. For the height change of the position of the reference block, a shim is added to an auxiliary reference block with a large height change, so that when the height of the jack is adjusted, the height variation of the two auxiliary reference blocks is the same. By this method, the twisting deformation generated when the workpiece 1 is placed flat can be overcome, so that the bending deformation of the workpiece 1 can be more completely eliminated. ...

Embodiment 3

[0031] On the basis of Embodiment 1, as a further optimization of the technical solution of the present invention, in order to facilitate the elimination of the bending deformation of the workpiece 1, in step 2, when selecting the measuring reference point 9, it is necessary to ensure that the supporting surface 6 of the flat pad corresponds to A measurement reference point 9 is provided at a position on the measurement reference plane 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com