Float coal pressing device of stamping coke oven coal side-charging car

A technology of tamping coke ovens and side loading, which is applied in charging devices, coke ovens, petroleum industry, etc., can solve the problems of environmental pollution, disrupted production rhythm, and insufficient humanization, and achieves convenient, fast, accurate, and effective operation. The effect of good and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

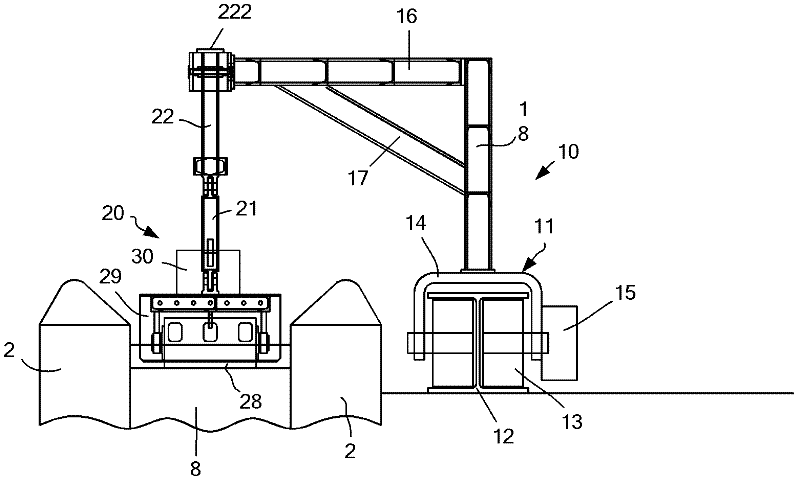

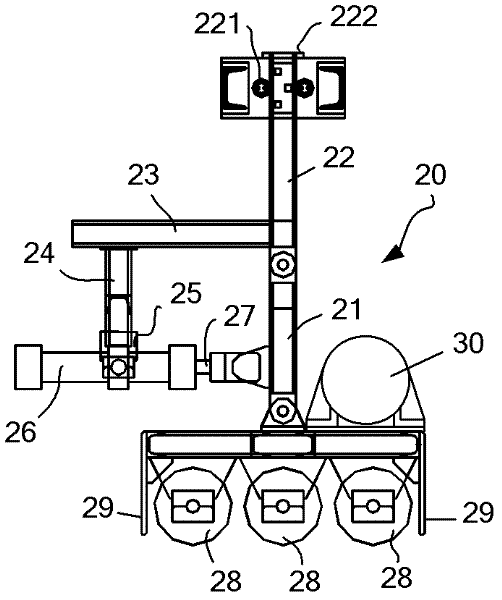

[0024] Such as figure 2 As shown, the present invention includes a bracket 10 and a vibrating base 20 . The support 10 is the main supporting structure of the present invention, supporting the vibrating seat 20;

[0025] The main body of the support 10 is a columnar structure, and a reciprocating mechanism 11 is installed at the bottom, which can move along the extension direction of the coal tank 8 . This reciprocating mechanism 11 can adopt refitting car to realize. In this embodiment, since the working position is relatively fixed, the reciprocating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com