Water flow accelerating pipe

A technology for accelerating pipes and water flow, which is applied in the main water supply pipeline, sewage pipeline system, water supply pipeline system, etc., and can solve the problems of increased consumption of water pumps, increased energy consumption, and increased electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

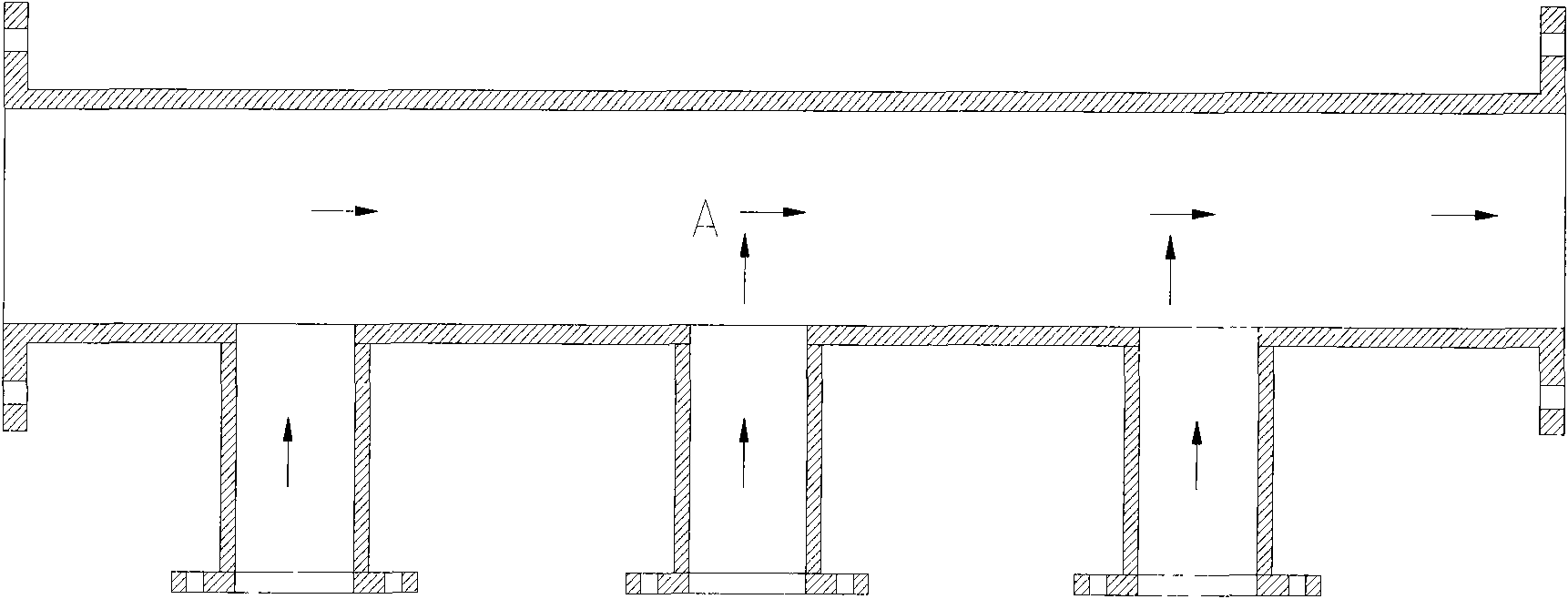

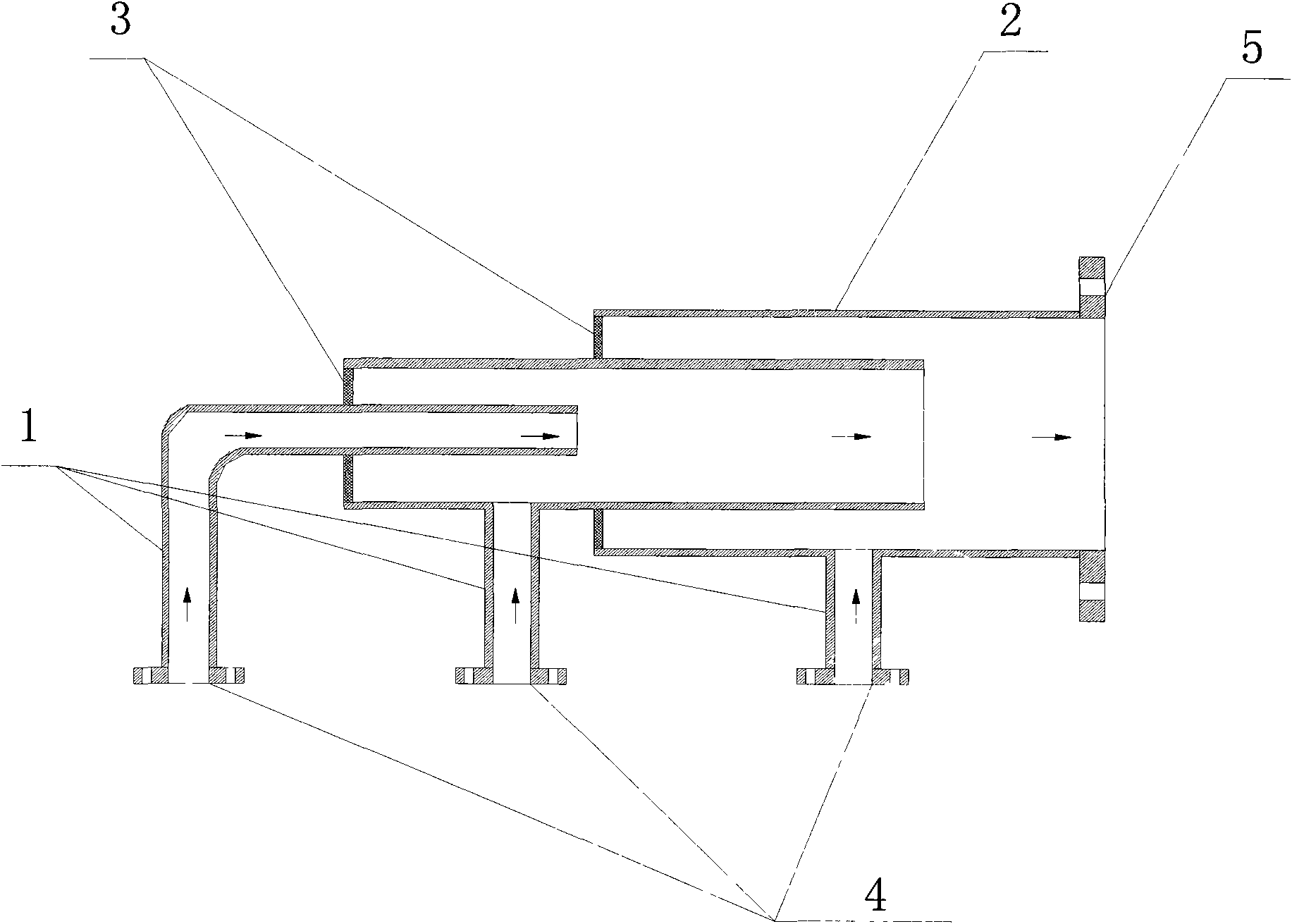

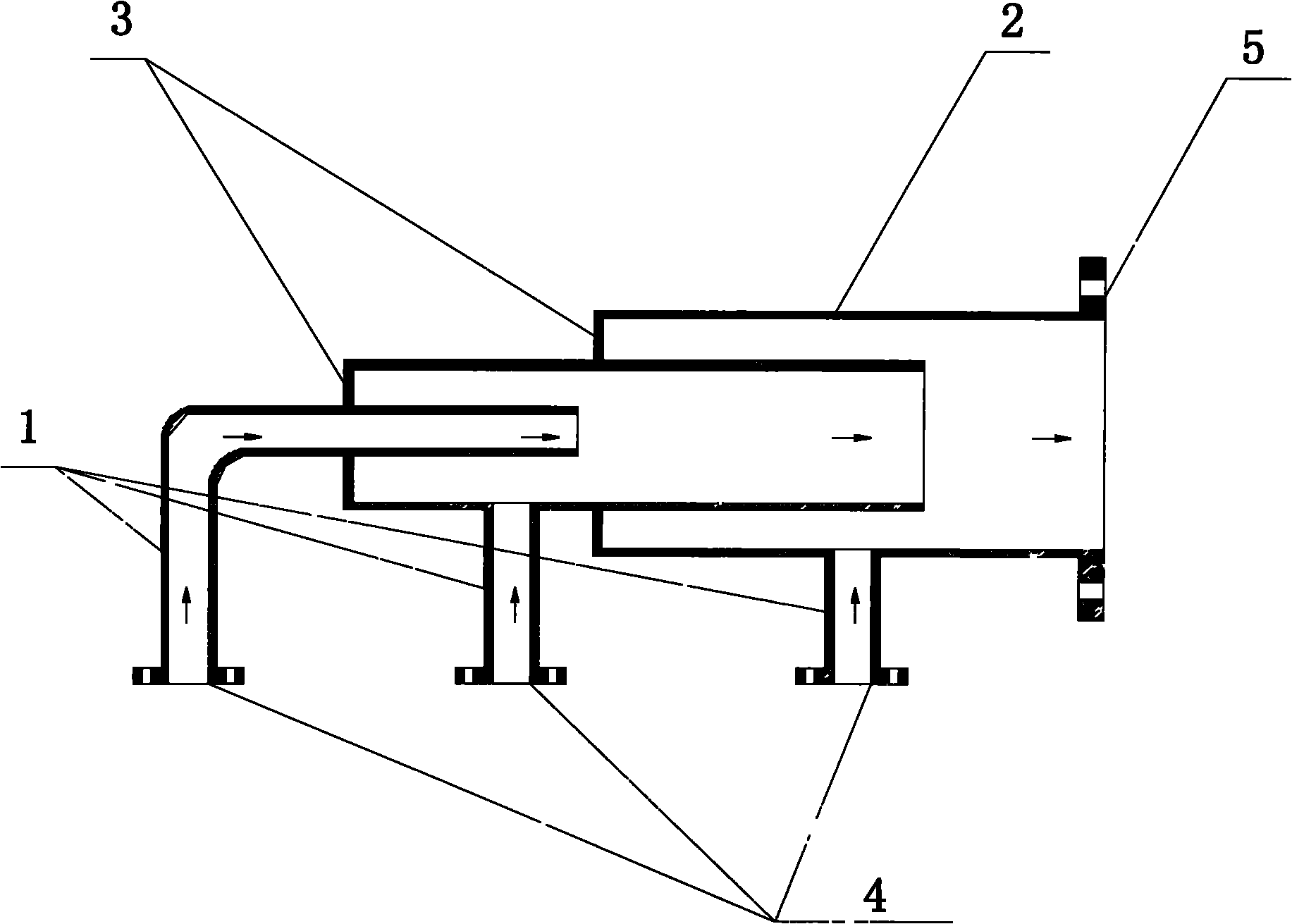

[0008] Such as figure 2 A water flow accelerating tube shown: it is composed of a branch pipe 1, a combination pipe 2, a sealing plate 3, and a flange 4. One end of the branch pipe 1 is welded to the combination pipe 2, and the other end is a water inlet connection port, and the water inlet branch 1 pipe Combination pipe 2 is composed of multiple pipes with different diameters welded by sealing plate 3. The combination pipe 2 is also welded with a flange nozzle 5 connected to the water outlet main pipe. The size of the pipe combination 2 is according to the flow direction (The arrows in the figure indicate the direction of water flow) are arranged from small to large. The small pipes extend into the large pipes and extend to the position of the connecting branch beyond the large pipes. The diameter of the large pipes is enough to satisfy itself and the previous stage. In this way, when the water in the small pipe enters the large pipe, it avoids direct impact on the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com