Heat-sensitive umbrella type packer for sublevel mining

A packer, heat-sensitive technology, applied in the directions of sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve the problem that the overlying stratum cannot be sealed, the sealing effect is not very ideal, and the quality of the mined minerals is unfavorable. impact and other issues, to achieve the effect of reducing the degree of mutual pollution, huge social and economic benefits, and improving the purity of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment describe in further detail:

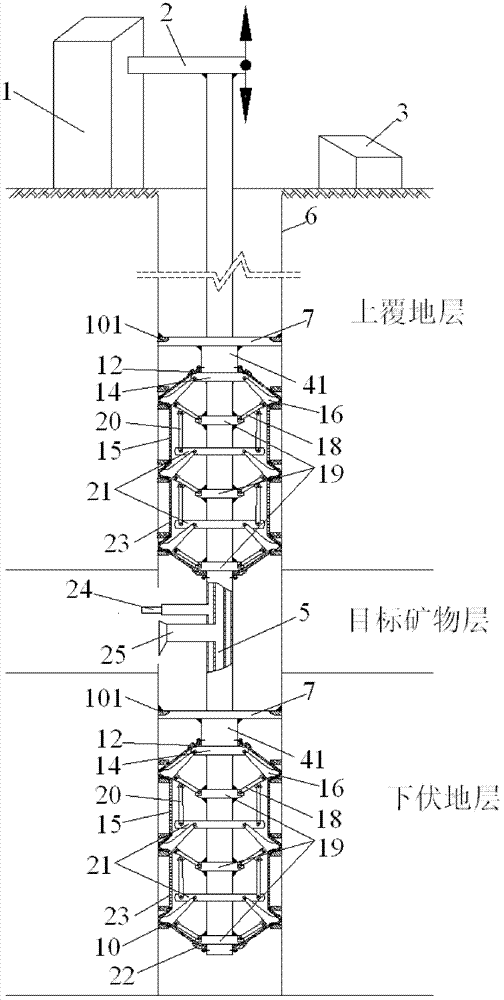

[0049] figure 1 It is an overall schematic diagram of the first embodiment of the present invention, as shown in the figure, a heat-sensitive umbrella packer for staged mining, including a power module, a sealing module and a production module; the power module includes a drilling rig 1 , power head 2 and pump 3;

[0050] The isolation module has an upper and lower two-level umbrella-shaped isolation bar system with the same structure, which are respectively located at the lower boundary between the target mineral layer and the overlying stratum, and at the upper boundary between the target mineral layer and the underlying stratum;

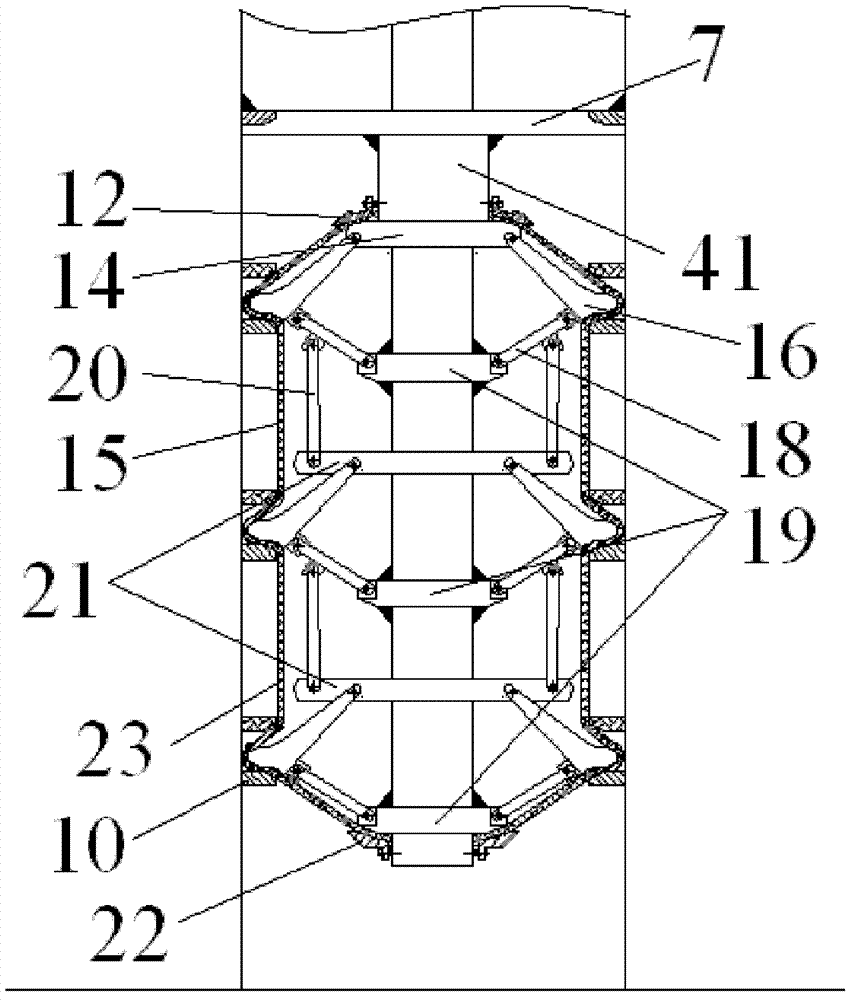

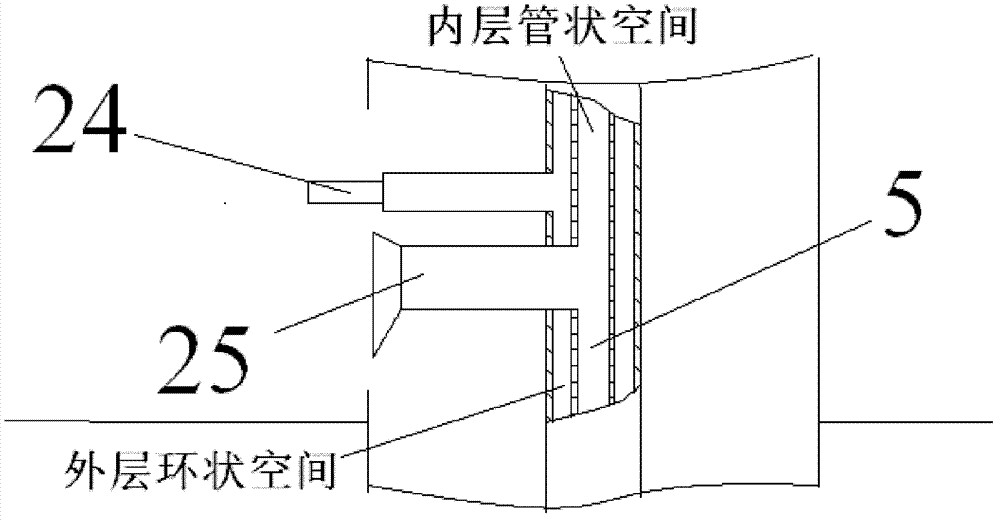

[0051] figure 2 It is a schematic diagram of the umbrella-shaped packing rod system at the lower part of the isolation module. The lower pressure plate 19 and the lower gland 22 of the umbrella-shaped packing rod system are fixedly connected to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com