Fine coal slurry sealing method

A technology of fine coal and slurry sealing, which is applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc., can solve the problems of large material consumption, poor sealing effect, inconvenient operation, etc., so as to reduce mining costs, Suitable for promotion, implementation, deployment and simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

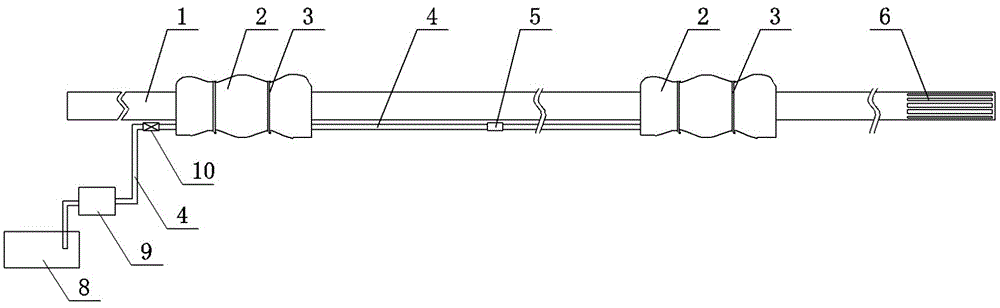

[0011] Embodiment 1: a kind of fine coal slurry hole sealing method, at first configuration raw material: to figure 1 Add the following weight percentage composition in the agitator 8 in the: fine coal powder 60~70%, cement 25~35%, white latex 4~6%, stir and make fine coal mixture; Add water again and continue to stir, make water and The proportion of fine coal mixture is 0.3-0.5.

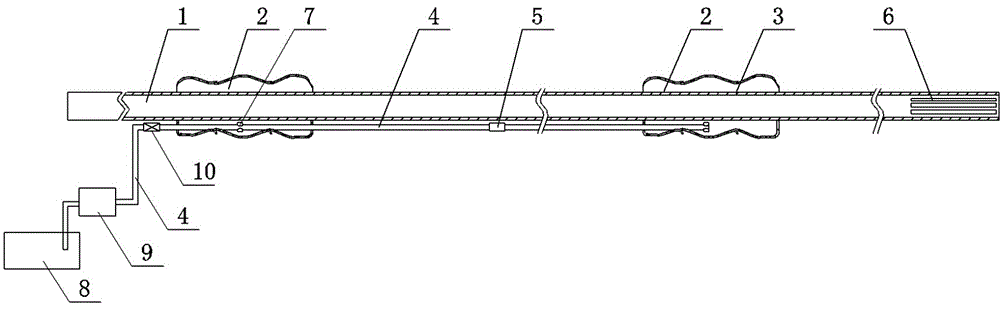

[0012] Secondly, if figure 1 and figure 2 , using a grouting pump to transport and press the fine coal slurry into the grouting port of the grouting sealing device. Front and rear bladders 2 are sequentially fixed on the body of the gas extraction pipe 1, and the distance between the bladders 2 at both ends of the gas extraction pipe 1 is 3m to 15m. A grouting pipe 4 is connected through each bladder 2, and the grouting tube 4 communicates with the inner cavity of the bladder 2 through a branch pipe, and a one-way valve 7 is installed on the branch pipe, and the end of the grouting pipe 4 is fi...

Embodiment 2

[0013] Embodiment 2: The content is basically the same as in Example 1, and the similarities are not repeated. The difference is: the weight percentages of the components of the fine coal mixture: fine coal powder 65~70%, cement 27~30%, white latex 5~ 6%. Then add water and continue stirring, so that the ratio of water to fine coal mixture is 0.4-0.5.

Embodiment 3

[0014] Embodiment 3: content is basically the same as embodiment 2, and similarity is not repeated, and difference is: fine coal powder 68%, cement 27%, white latex 5%. Add water again and continue to stir so that the ratio of water to fine coal mixture is 0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com