Method of backfilling and sealing holes with coal cuttings in gas pre-drainage drilling holes

A gas drainage and pre-draining technology, which is used in gas drainage, earth-moving drilling, sealing/sealing, etc., can solve the problems of high consumption of materials, inconvenient operation, and poor sealing effect, so as to reduce mining costs and deploy Simple and convenient, suitable for promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

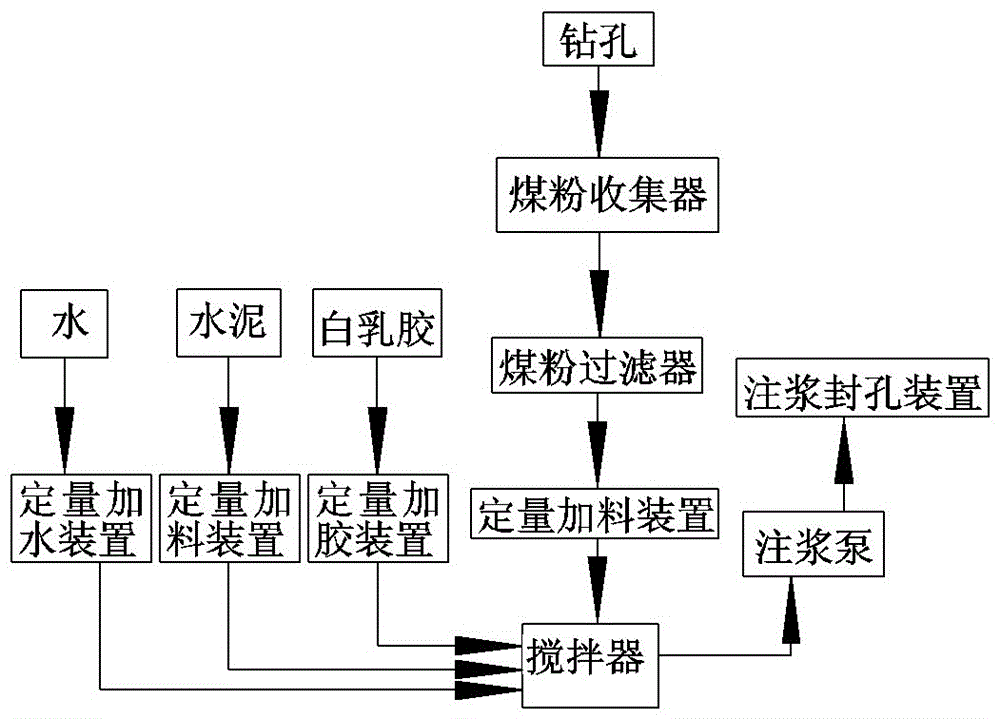

[0016] Embodiment 1: A method for backfilling and sealing holes with coal cuttings in gas pre-extraction drilling holes, see figure 1 , while using drilling tools to drill holes in the coal seam, the coal powder is collected and filtered or pulverized to keep the particle size of the coal powder not greater than 1mm; then, the filtered fine coal powder is input into the mixer and added cement and lime The latex is stirred to make a fine coal mixture.

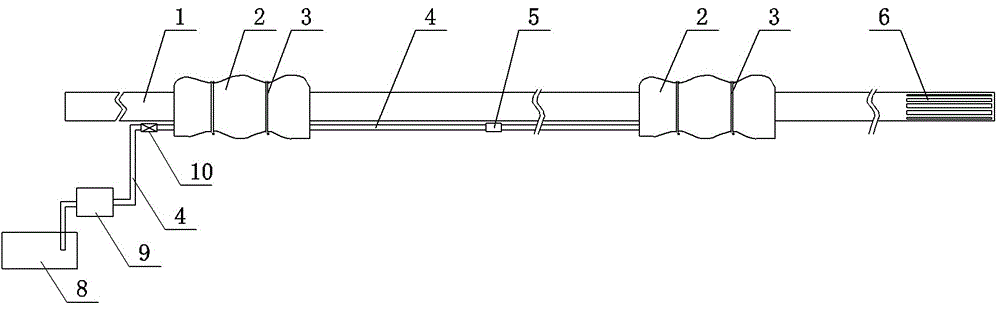

[0017] The raw materials for making the fine coal powder mixture can use a quantitative feeding device or a quantitative liquid feeding device. Among them, the quantitative feeding device can be controlled by a valve, and the quantitative feeding device can be used such as Figure 5 the structure described. Figure 5 Among them, the quantitative feeding device includes a recumbent cylindrical silo 11 and a revolving drum 14 installed in the cylindrical silo. The upper and lower sides of the cylindrical silo 11 are respectively...

Embodiment 2

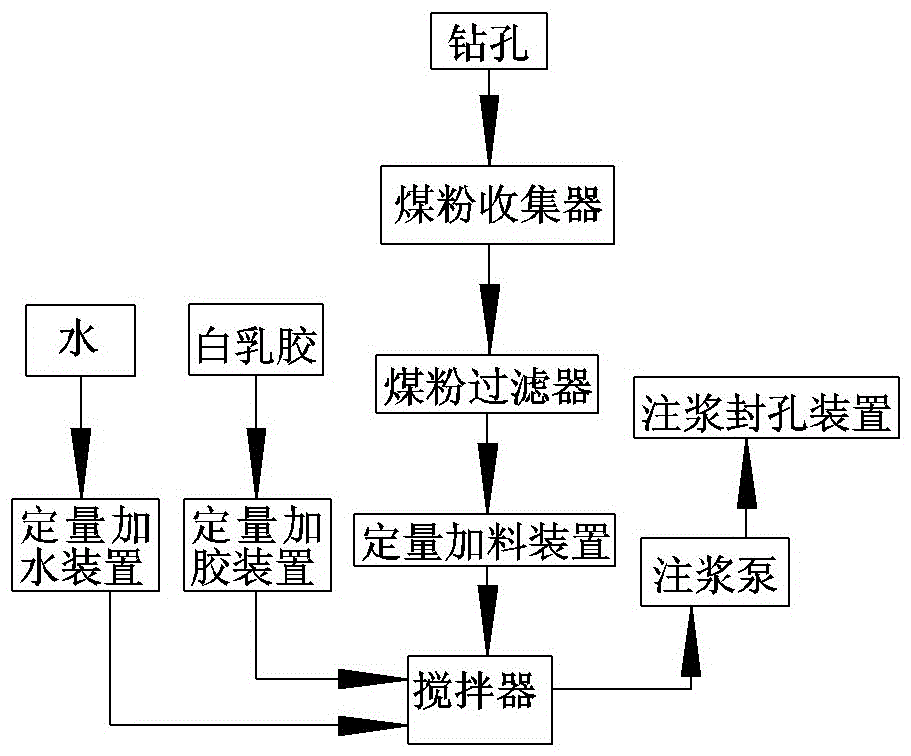

[0021] Embodiment 2: The content is basically the same as in Example 1, and the similarities are not repeated. The difference is: the weight percentages of the components of the fine coal mixture: fine coal powder 65~70%, cement 27~30%, white latex 5~ 6%. Then add water and continue stirring, so that the ratio of water to fine coal mixture is 0.4-0.5.

Embodiment 3

[0022] Embodiment 3: content is basically the same as embodiment 2, and similarity is not repeated, and difference is: fine coal powder 68%, cement 27%, white latex 5%. Add water again and continue to stir so that the ratio of water to fine coal mixture is 0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com